Making method of integrated multifunctional wall module and multifunctional wall module

A manufacturing method and an integrated technology, applied in the fields of wooden house walls and building walls, can solve the problems of high cost, complicated manufacturing process, poor operability, etc., and achieve the advantages of simple installation and operation, simple production process and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

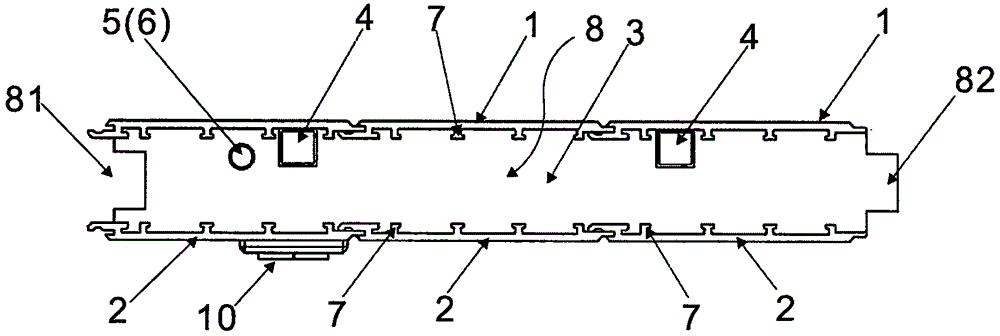

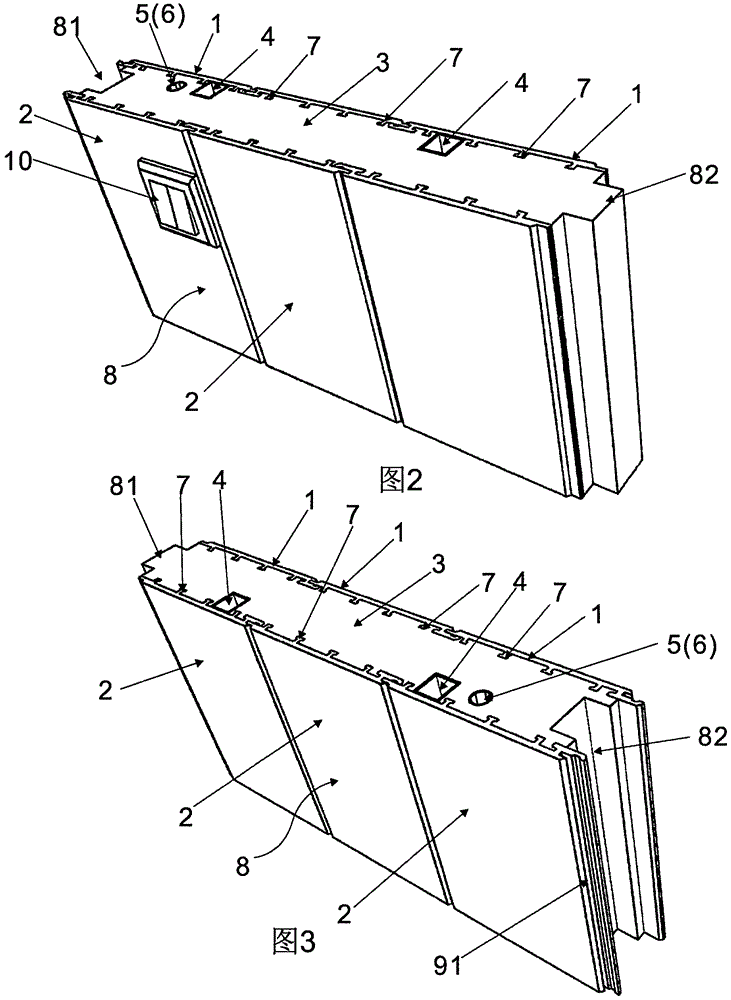

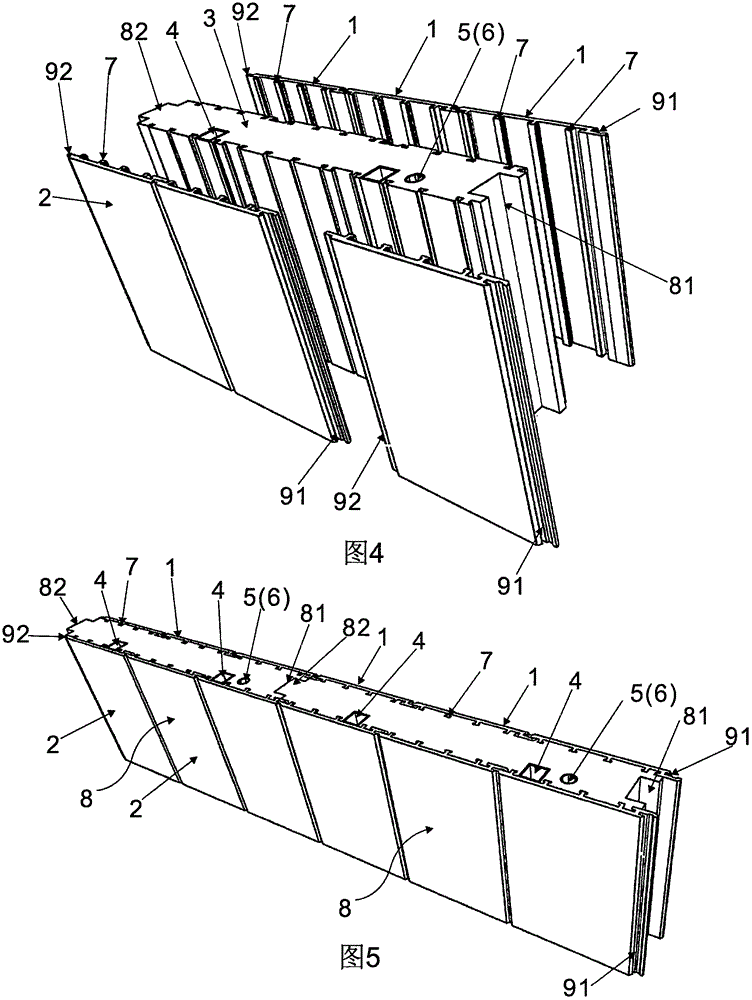

[0035] Such as Figure 1 to Figure 4 The one-piece multi-functional wall module shown includes an inner wall panel 1 and an outer wall panel 2, and the inner wall panel 1 and the outer wall panel 2 are filled and fixed by fluid thermal insulation materials 3 to form a One-piece wall module8.

[0036] Specifically, the inner wall panels 1 and the outer wall panels 2 are wood-based panels, solid wood panels, and aluminum panels. In order to meet the requirements of energy saving and environmental protection, artificial panels such as wood-plastic panels are preferred. One side of the wall module 8 is provided with an installation groove 81, and the other side is provided with an installation protrusion 82. When the installation groove 81 and the installation protrusion 82 act on two adjacent wall modules 8 when they are installed, a The installation groove 81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com