Complex reverse osmosis membrane

A technology of reverse osmosis membrane and compound, applied in the field of water treatment, to achieve the effect of improving performance, improving compactness, reducing engineering investment and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

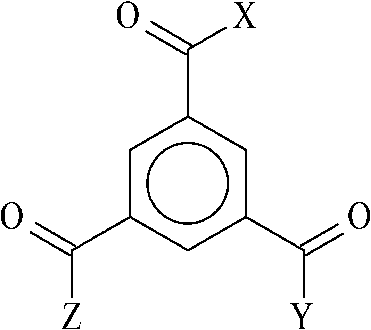

[0035] A porous polysulfone support membrane composed of a DMF solution containing 16% polysulfone was used and placed in a 3.5% m-phenylenediamine (MPDA) solution for about 1 minute. The amine solutions each contained 0.1 wt% sodium dodecylsulfonate (SDBS) surfactant. The support film soaked in MDPA was placed on a paper towel and rolled with a rubber roller to remove excess solution on the front and back. The above steps and the amount of polyamine used are the same as those in the prior art for preparing the polyamide layer. This support layer was then contacted with an organic solution listed in Table 1 containing 0.15% (wt / v%) of acid chloride (-COCl) for 50 seconds to form a polyamide layer. Then keep it in an oven at 140° C. for 10 minutes to obtain the final composite reverse osmosis membrane.

[0036] Use an aqueous solution containing 32800ppm of sodium chloride, pH 7.5, and test under the condition of 800psi for 1 hour to obtain the initial performance of the memb...

Embodiment 7

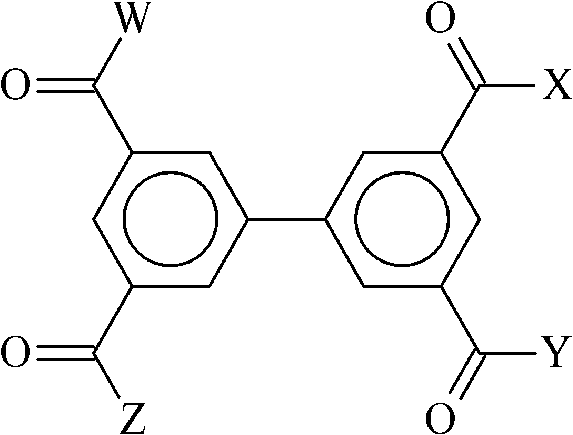

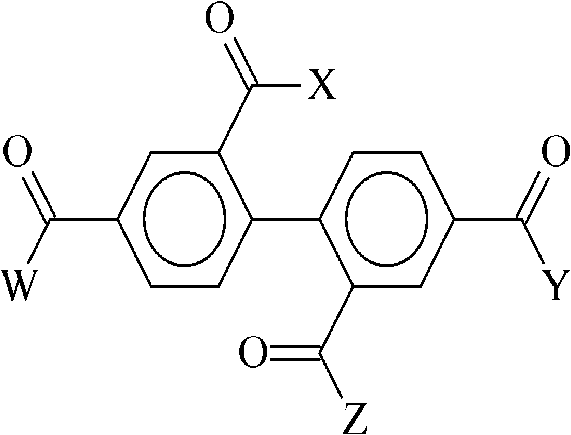

[0041] Except that 2,2',4,4'-biphenyl tetracarbonyl chloride was used instead of 3,3',5,5'-biphenyl tetracarbonyl chloride, a composite reverse osmosis membrane was prepared by the same operation as in Example 4. Then using the same test method as in Example 4, the initial desalination rate of the membrane was 99.80%, and the water flux was 19.3GFD. After running for 6 hours, the desalination rate was 99.75%, and the water flux was 19.0GFD.

Embodiment 8

[0043]Except that 3,3',5,5'-biphenyltetracarbonyl bromide was used instead of 3,3',5,5'-biphenyltetracarbonyl chloride, a composite reverse osmosis membrane was prepared by the same operation as in Example 4 . Then using the same test method as in Example 4, the initial desalination rate of the membrane was 99.78%, and the water flux was 19.9GFD. After running for 6 hours, the desalination rate was 99.72%, and the water flux was 19.2GFD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com