Electrolyte vacuum boiling type high speed electro-deposition method and device thereof

A technology of vacuum boiling and electrolyte, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of harmful oxides, slow deposition speed, low deposition speed, etc. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

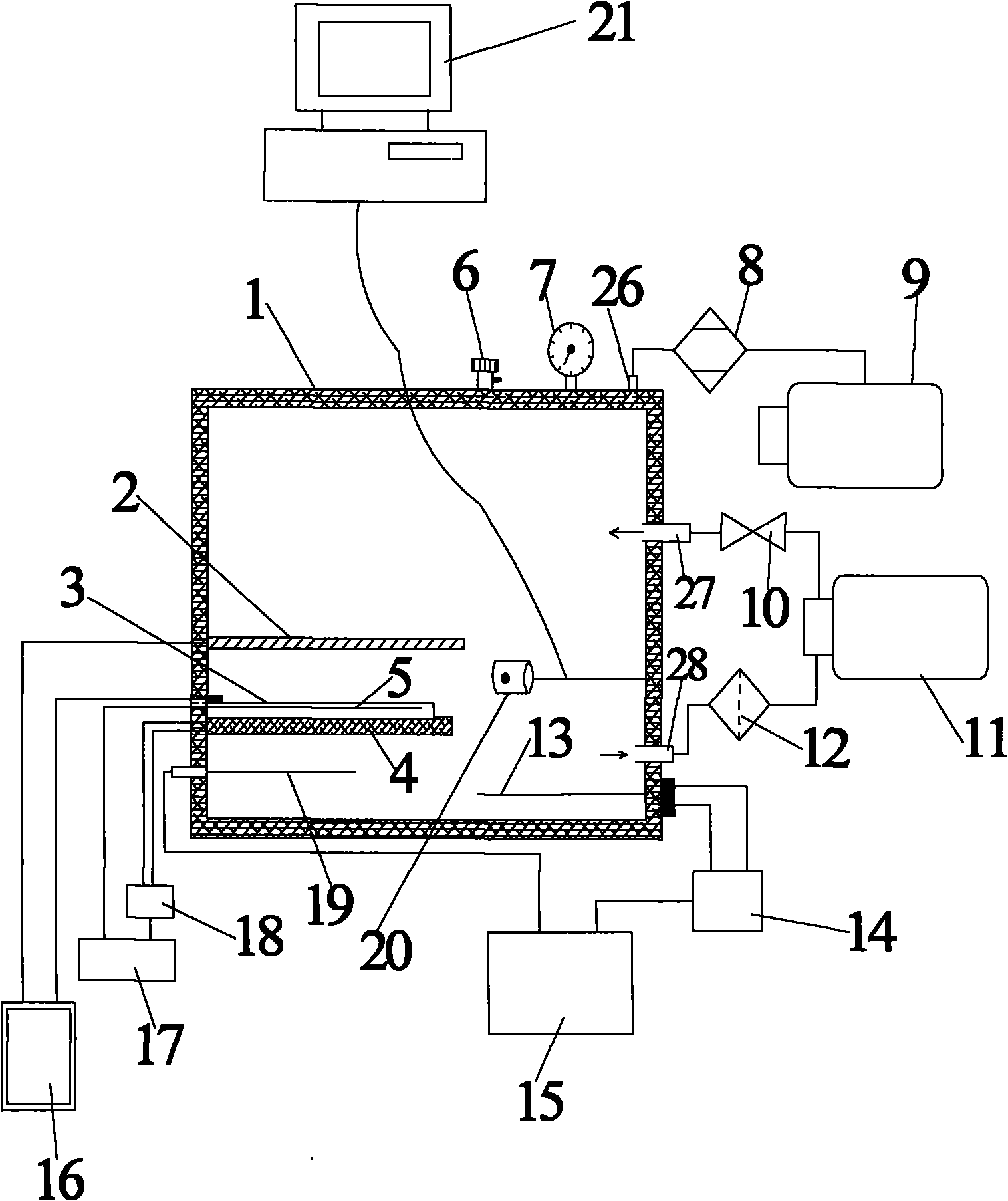

[0046] The concrete operating steps of the inventive method are:

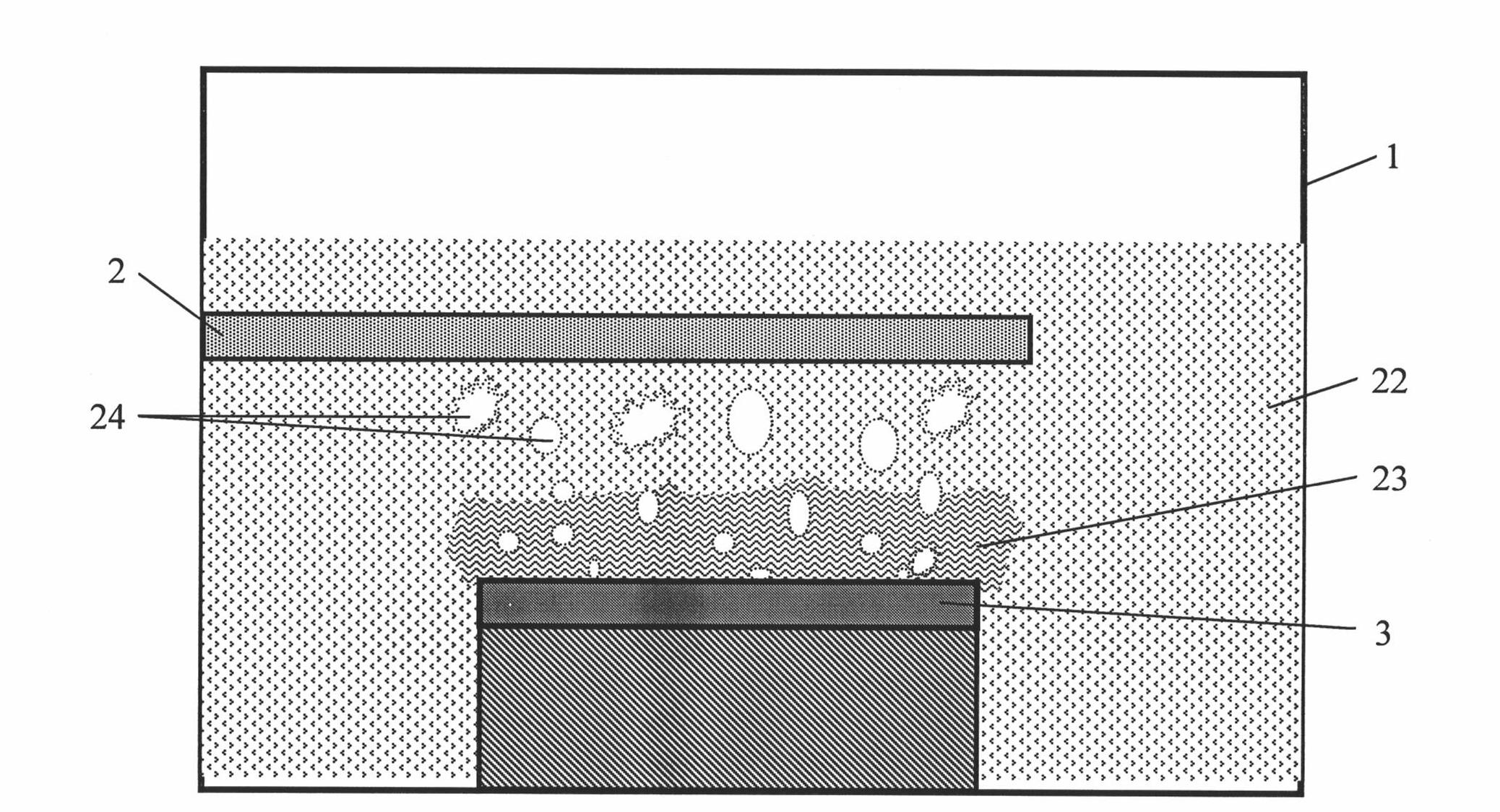

[0047] a. The negative electrode 3 that thermocouple 5 is housed is fixedly pasted on the stainless steel heating plate 4 (heating plate 4 is fixed on the side wall of electrodeposition tank 1) that has corrosion-resistant electric insulating layer outside, then the electrolysis with anode bag The nickel anode plate 2 is fixed on the side wall of the electrodeposition tank 1 (wherein the anode and the cathode are relatively horizontally arranged up and down, the distance between the two is 35mm, the area ratio of the anode and the cathode is 2.5:1, and the cathode 3 and the anode 2 are respectively connected to the power supply 16 Negative and positive poles), add an appropriate amount of sulfamate electrolyte 22 to the electrodeposition tank 1 (see Table 1 for the composition of the electrolyte, the liquid level of the electrolyte added exceeds the upper surface of the anode by 25 mm) and then seals the electro...

Embodiment 2

[0055] In this embodiment, the current density used is 51A / dm 2 , other implementation steps and electroforming conditions are the same as in Example 1.

[0056] Table 2 Microhardness and deposition rate of Example 1, Example 2 and contrast nickel sheet

[0057]

[0058] Note: Operating conditions of Example 1: vacuum degree 5kPa, electrolyte temperature 35°C, cathode surface temperature 65°C, current density 7A / dm 2 ;Example 2 Operating conditions: vacuum degree 5kPa, electrolyte temperature 35°C, cathode surface temperature 65°C, current density 51A / dm 2 ;Contrast nickel sheet operating conditions: normal pressure, electrolyte constant temperature 50 ℃, current density 7A / dm 2 .

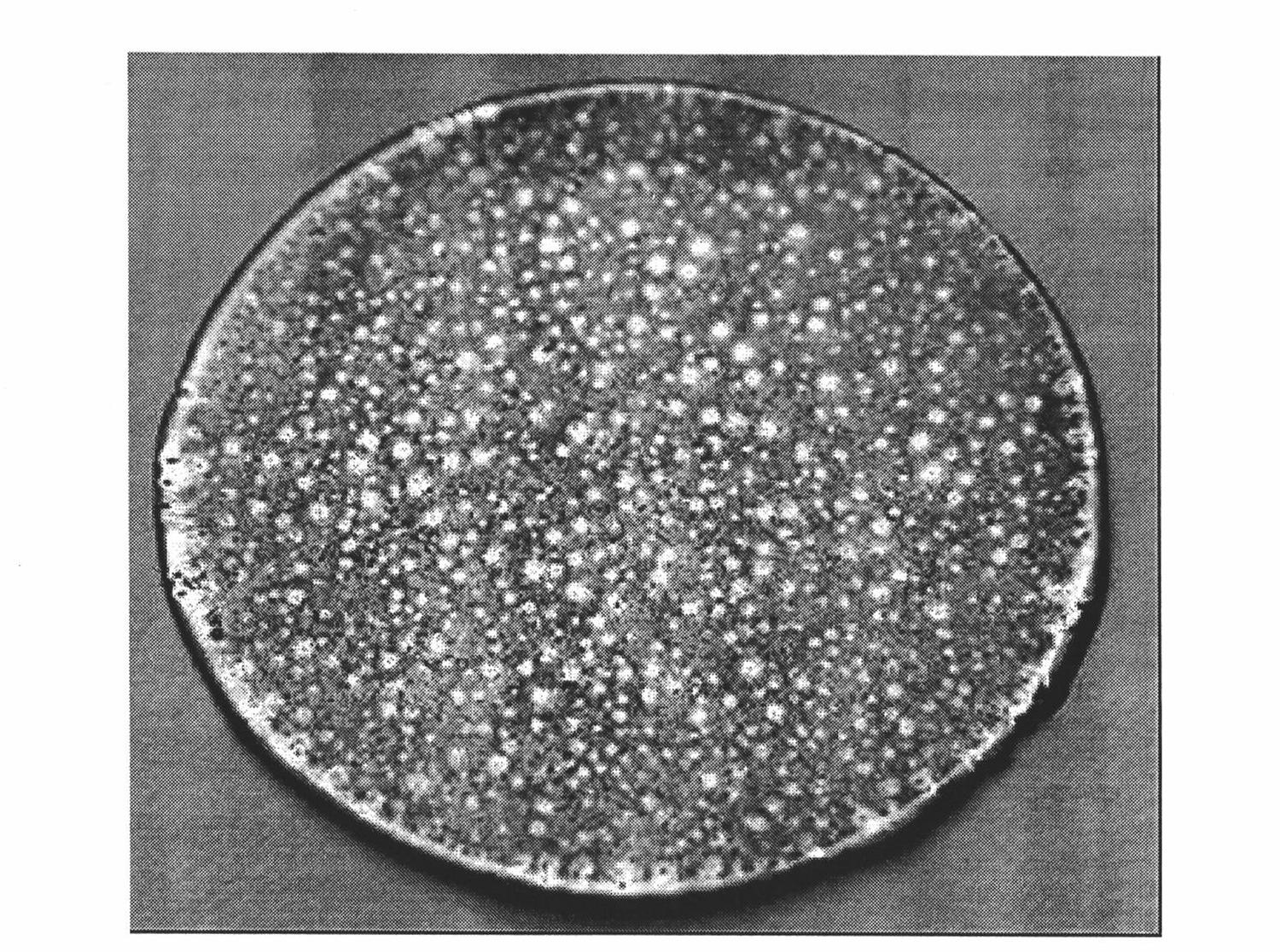

[0059] The topography of the electrodeposited nickel sheet prepared by the method described in Example 2 is shown in Figure 5 , the microhardness of the nickel sheet and the deposition rate during the electroforming process are shown in Table 2. Depend on Figure 5 It can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com