Waterproof cement additive and cement containing same

An additive and cement technology, applied in the field of cement, can solve the problems of inconvenient storage and transportation of liquid resin, difficult construction and operation, non-corrosion and mildew resistance, etc., and achieves the effect of strong compactness, strong price advantage, and reduction of micro-cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] Example 1. A cement waterproof additive, the preparation method is as follows:

[0044] Dissolve 9.4g of polyvinyl alcohol into 120mL of distilled water, add 5.8mL of methyl acrylate and 0.4g of cerium ammonium sulfate as the initiator to the solution, place the system in a water bath and vent nitrogen through the system for half an hour, and then The temperature of the pot is adjusted to 70°C, and the cement waterproof additive is obtained by reacting for 8 hours, which is a graft copolymer emulsion.

example 2

[0045] Example 2. A cement waterproof additive, the preparation method is as follows:

[0046] The steps are the same as in Example 1, except that the ratio of polyvinyl alcohol: methyl acrylate is g: ml=2:1-1.7, and the weight ratio of the polyvinyl alcohol: initiator is 20-25:1. Initiator is cerium ammonium sulfate

example 3

[0047] Example 3. A cement waterproof additive, the preparation method is as follows:

[0048] The steps are the same as in Example 1, except that the ratio of polyvinyl alcohol: methyl acrylate is g: ml=1.62, and the weight ratio of the polyvinyl alcohol: initiator is 23.5.

[0049] The reaction formula is as follows:

[0050]

[0051]

[0052] Using the synthetic route shown in the figure above, polyvinyl alcohol and methyl acrylate are used for free radical polymerization under the catalysis of cerium sulfate to generate polyvinyl alcohol polymethyl acrylate copolymer and polymethyl acrylate homopolymer. figure 1 It is an emulsion of the polymer obtained after the reaction.

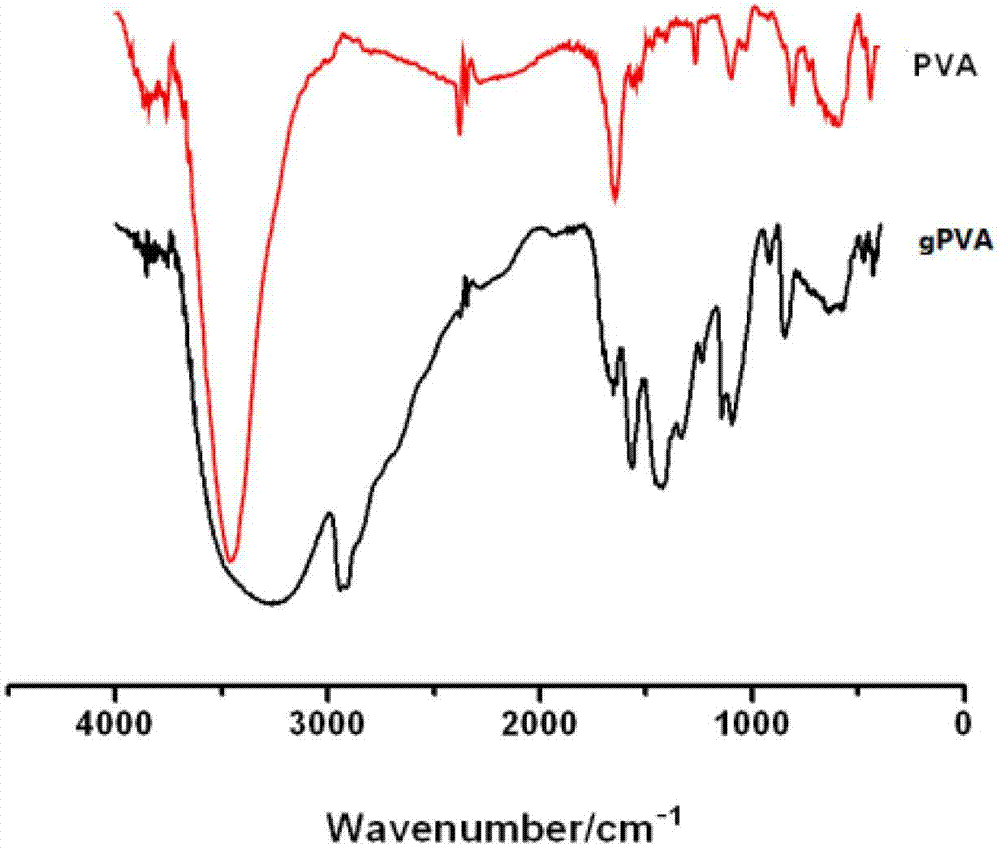

[0053] From figure 2 It can be seen in the infrared spectrum of gPVA that the stretching vibration peak of the hydroxyl group at 3249cm-1 is weakened, the hydrocarbon stretching vibration peak of the methyl group appears at 2930cm-1, and the ester appears at 1242cm-1. The stretching vibration peak of the carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com