Weakly-acidic high transparent soap and preparation method thereof

A transparent soap and weakly acidic technology, applied in the direction of chemical instruments and methods, surface active non-soap compounds and detergent compositions, shaped soap, etc., can solve the problems of long production time, unfavorable continuous operation, single chain length, etc., to achieve Large-scale industrial production, conducive to continuous production, and the effect of accelerating hardening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

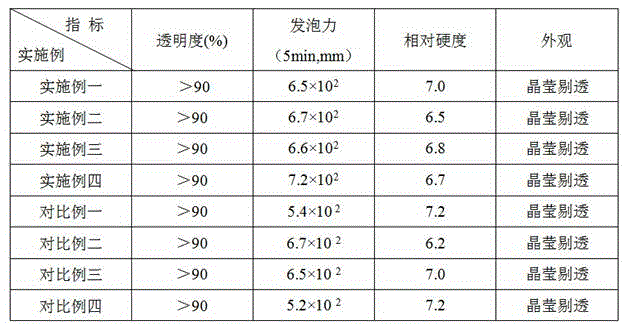

Examples

Embodiment 1

[0043] Lauroyl Glutamate 18%

[0044] Myristoyl Glutamate 6%

[0045] Hexadecyl Glutamic Acid 4%

[0046] Lauryl Glycine 9%

[0047] Lauroyl Sarcosine 5%

[0048] Lauramide Hydroxypropyl Betaine 5%

[0049] Moisturizer 15%

[0050] Alcohol 5%

[0051] Triethanolamine 24%

[0052] Deionized water 7%

[0053] Butylated hydroxytoluene 2%.

[0054] Clear Soap Preparation:

[0055] (1) Take humectant and water according to the ratio, mix and heat to 80°C, and keep the temperature constant.

[0056] (2) Add lauroyl glutamic acid, myristoyl glutamic acid, palmitic acid glutamic acid, lauroyl glycine and lauroyl sarcosine to dissolve and mix well.

[0057] (3) Add lauramide hydroxypropyl betaine and dibutyl hydroxytoluene to dissolve and mix well.

[0058] (4) Add triethanolamine dropwise to adjust the pH value to 6.5.

[0059] (5) Spray alcohol to eliminate foam on the surface of the liquid.

[0060] (6) Cool until hardened, demolded, and stamped.

Embodiment 2

[0062] Lauroyl Glutamate 17%

[0063] Myristoyl Glutamic Acid 5%

[0064] Palmitoyl Glutamic Acid 3%

[0065] Lauryl Glycine 8%

[0066] Lauroyl Sarcosine 8%

[0067] Lauramide Hydroxypropyl Betaine 6%

[0068] Moisturizer 18%

[0069] Alcohol 5%

[0070] Triethanolamine 23%

[0071] Deionized water 4%

[0072] Butylated Hydroxytoluene 3%

[0073] Clear Soap Preparation:

[0074] (1) Take humectant and water according to the ratio, mix and heat to 70°C, and keep the temperature constant.

[0075] (2) Add lauroyl glutamic acid, myristoyl glutamic acid, palmitic acid glutamic acid, lauroyl glycine and lauroyl sarcosine to dissolve and mix well.

[0076] (3) Add lauramide hydroxypropyl betaine and dibutyl hydroxytoluene to dissolve and mix well.

[0077] (4) Add triethanolamine dropwise to adjust the pH value to 6.

[0078] (5) Spray alcohol to eliminate foam on the surface of the liquid.

[0079] (6) Cool until hardened, demolded, and stamped.

Embodiment 3

[0081] Lauroyl Glutamate 17.5%

[0082] Myristoyl Glutamate 6.5%

[0083] Cetyl glutamate 4.5%

[0084] Lauryl Glycine 8.5%

[0085] Lauroyl Sarcosine 5.5%

[0086] Lauramide Hydroxypropyl Betaine 8%

[0087] Moisturizer 16%

[0088] Alcohol 5%

[0089] Triethanolamine 20%

[0090] Deionized water 6%

[0091] Butylated Hydroxytoluene 2.5%

[0092] Clear Soap Preparation:

[0093] (1) Take humectant and water according to the ratio, mix and heat to 75°C, and keep the temperature constant.

[0094] (2) Add lauroyl glutamic acid, myristoyl glutamic acid, palmitic acid glutamic acid, lauroyl glycine and lauroyl sarcosine to dissolve and mix well.

[0095] (3) Add lauramide hydroxypropyl betaine and dibutyl hydroxytoluene to dissolve and mix well.

[0096] (4) Add triethanolamine dropwise to adjust the pH value to 6.3.

[0097] (5) Spray alcohol to eliminate foam on the surface of the liquid.

[0098] (6) Cool until hardened, demolded, and stamped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com