Preparation method of plant oil from blackberry seeds

A salad oil and seed technology, which is applied in food preparation, edible oil/fat, food science, etc., can solve the problem that seed oil has not been developed and utilized, achieve crystal clear appearance, improve enterprise economic benefits, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

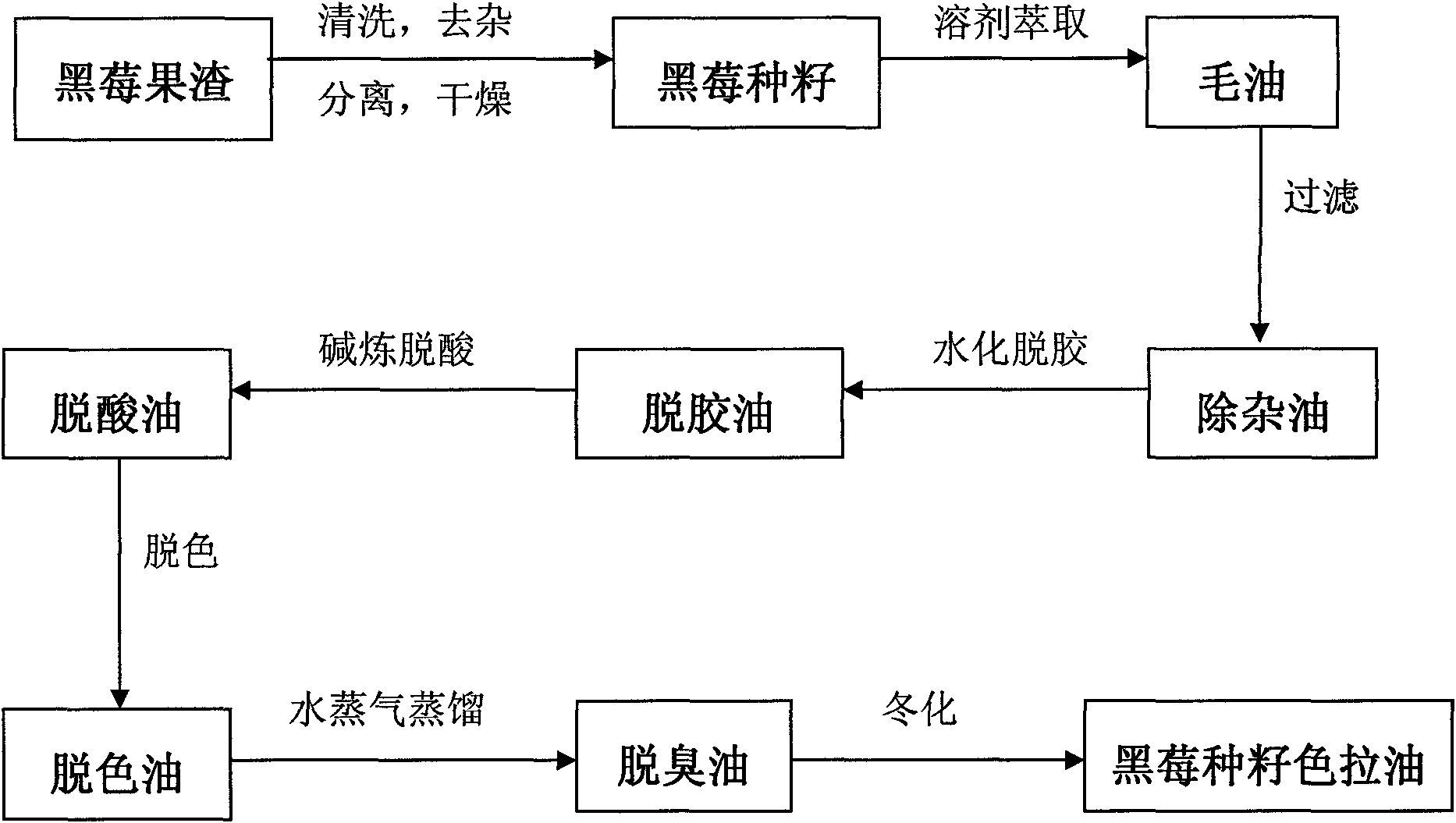

Method used

Image

Examples

Embodiment example 1

[0024] Implementation case 1: Take 100kg of blackberry wet pomace as an example to process blackberry seed salad oil.

[0025] Take 100kg of blackberry wet pomace, wash, remove impurities and separate to obtain pure, mildew-free blackberry seeds. The seeds were placed in an air blast drying oven and kept at 50° C. for 4 hours to obtain 21.2 kg of seeds with a moisture content of 6.83%. The dried seeds were crushed, passed through a 20-mesh sieve, extracted with a mixture (1:1) of n-hexane and petroleum ether (30-60), the amount of solvent was 95kg, and the temperature was kept at 40°C for 2 hours. The mixture after the extraction enters a rotary evaporator, and the solvent is recovered at 0.095~0.097Mpa and 40°C to obtain 2.756 kg of blackberry seed crude oil, an acid value of 2.31 mg KOH / g, an iodine value of 160.16 g / 100 g, and a refractive index of 1.4780 ( 25°C), saponification value 193.76mg KOH / g, peroxide value 30.40mmol / kg, unsaponifiable matter 27.73g / kg.

[0026] H...

Embodiment example 2

[0027] Implementation case 2: Take 50kg of dried blackberry pomace as an example to process blackberry seed salad oil.

[0028] Get 50kg of dried blackberry pomace after natural air-drying, separate by sieving, remove impurities such as pericarp, and obtain pure, mildew-free blackberry seeds with a moisture content of 11.71%. The seeds were placed in an air blast drying oven and kept at 50° C. for 3.5 hours to obtain 25.7 kg of seeds with a moisture content of 7.62%. The dried seeds were crushed, passed through a 20-mesh sieve, extracted with a mixture (1:1) of n-hexane and petroleum ether (30-60), the amount of solvent was 95kg, and the temperature was kept at 42°C for 2 hours. The extracted mixture enters a rotary evaporator, and the solvent is recovered in batches under the conditions of 0.095-0.097Mpa and 40°C. A total of 3.169kg of blackberry seed crude oil is obtained, the acid value is 2.82mg KOH / g, the iodine value is 183.52g / 100g, and the refractive index Rate 1.4788...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com