Cushioning flooring material and manufacturing method therefor

A technology of floor material and buffer layer, applied in building structure, floor, covering/lining, etc., can solve the problems of environmental burden, residue, surface treatment layer wear and may disappear, etc., to prevent interlayer noise, appearance, etc. gorgeous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

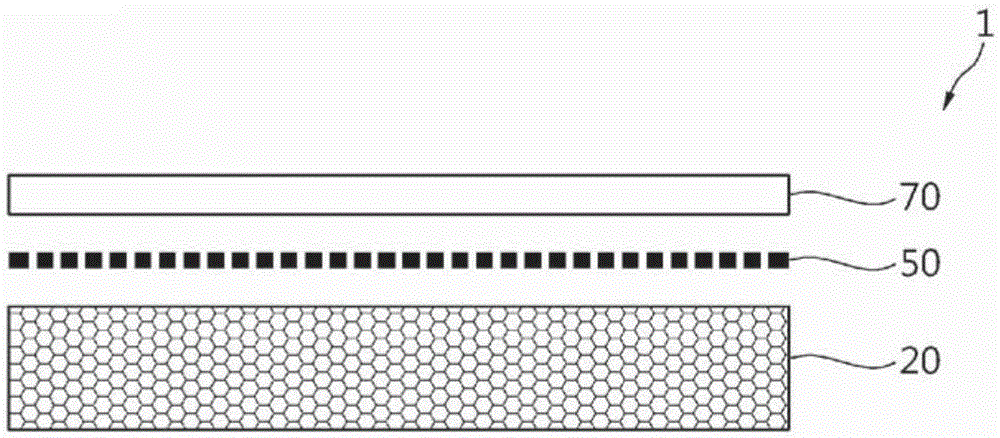

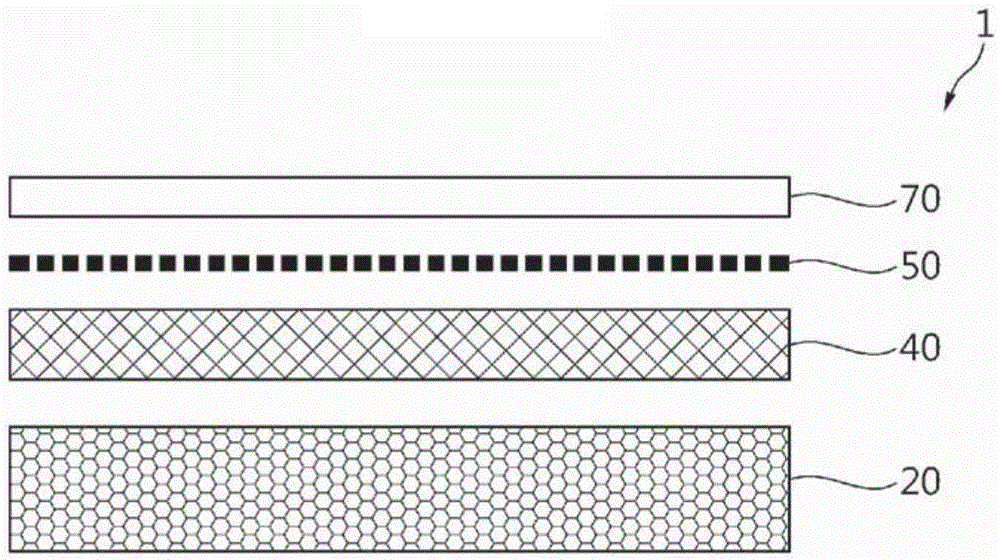

[0130] From the bottom to the top, the balance layer 10, buffer layer 20, backing paper layer 30, dimensionally stable layer 40, printing layer 50, transparent layer 60, elastic layer 70', and surface treatment layer 80 are stacked in sequence, and the transparent layer 60 A transparent PVC film is used, and the elastic layer 70' uses an elastic layer in which a composite resin of acrylic elastic resin and polylactic acid is mixed at a mixing ratio (weight ratio) of 60:40, and based on 100 parts by weight of the composite resin, The PEwax of 1 weight part of resin meter as lubricant has been mixed, and the elastic layer of making with the thickness of 0.2mm, thus made the buffer floor material 1 (referring to that the total thickness of the present invention is 4.5mm) Figure 5 ).

Embodiment 2

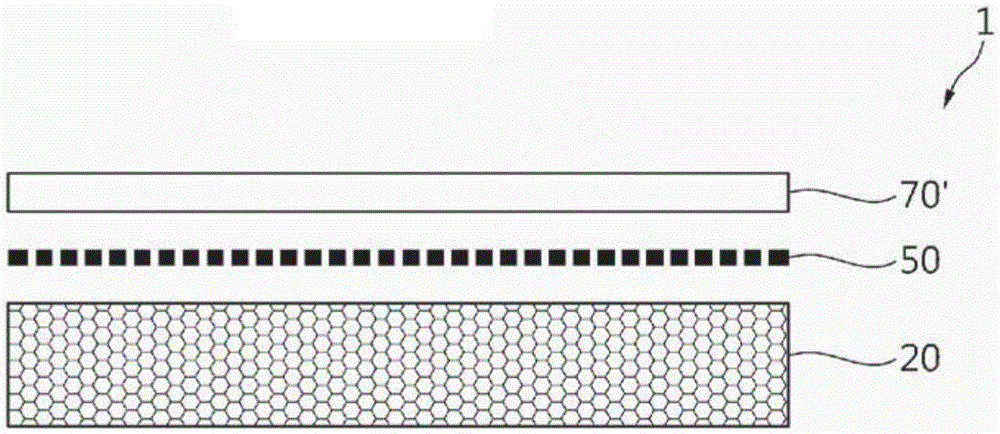

[0132] In Example 1, the same method as in Example 1 was carried out except that the elastic layer 70' manufactured with a thickness of 0.5 mm was used instead of the transparent layer 60.

experiment example 1

[0136] The TVOC (Total Volatile Organic Compounds) emission of the buffer floor materials of Examples 1 and 2, and the commercialized existing floor material (Comparative Example 1) in which the transparent layer 60 constitutes the surface layer was compared. , and the results are shown in Table 1 below.

[0137] The measurement method of TVOC emission is carried out according to the Ministry of Environment Announcement No. 2010-24, the small chamber method of the indoor air quality engineering experiment standard, and the sample of the floor material as the experimental material is put into the mass spectrometer / high performance liquid In a small chamber with a volume of 20 L connected to chromatography (MS / HPLC), the TVOC released from the sample is collected from the small chamber and directly flows into the mass spectrometer / high performance liquid chromatography, thereby determining the The method of TVOC in the inflowing air is carried out, and other experimental conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com