A manufacturing method for multi-color plastic mobile phone key

A kind of multi-color, manufacturing method technology, applied in the direction of telephone structure and other directions, can solve the problems of poor wear resistance, dirty, single color, etc., to achieve the effect of improving hardness and wear resistance, improving single color and colorful color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

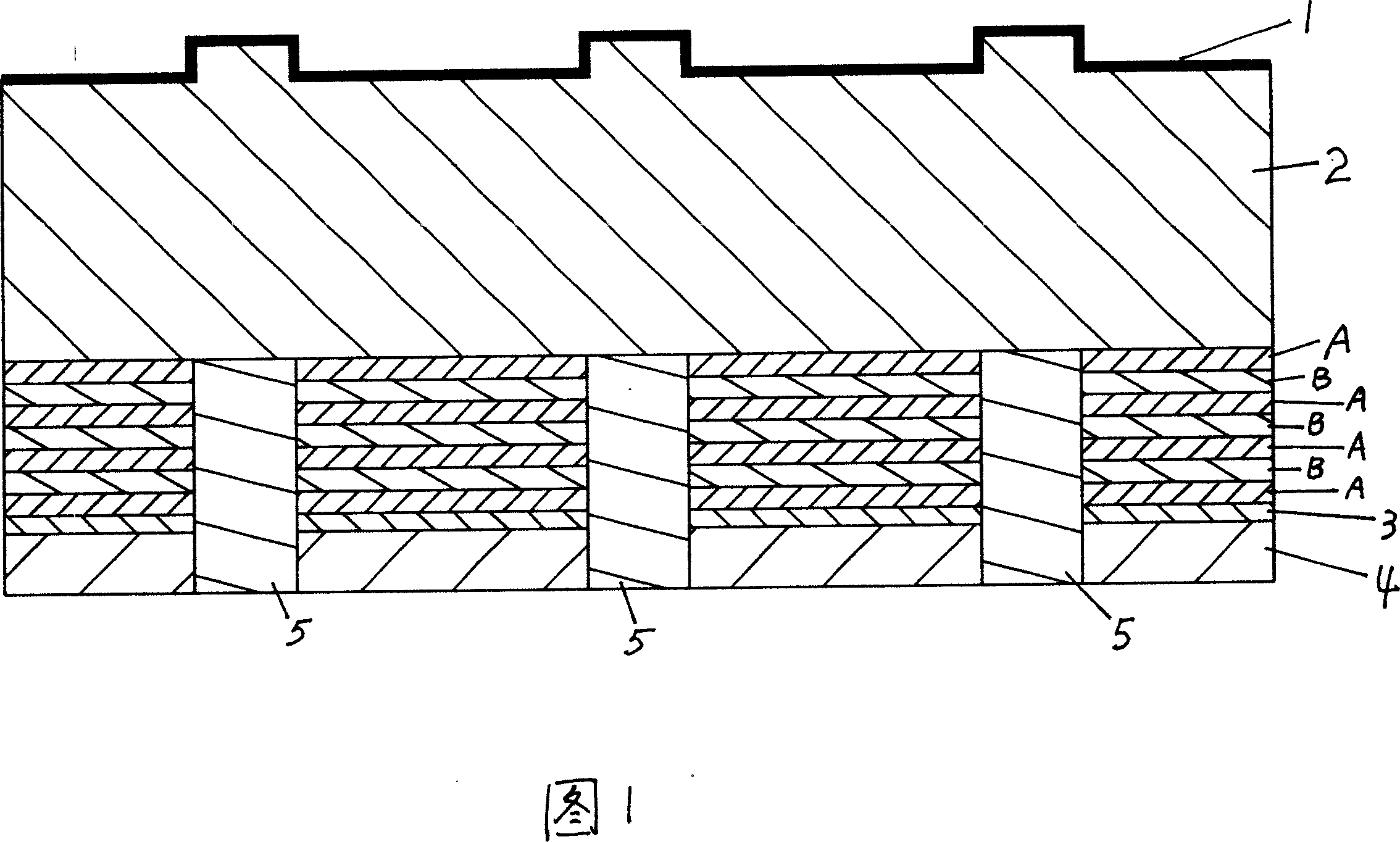

[0018] Set forth concrete implementation steps of the present invention below in conjunction with Fig. 1:

[0019] 1. Production of high-precision molds

[0020] Molds can be made according to customer product design requirements. Such as brushed pattern, CD pattern, mesh pattern, bright mist and other colors. The appearance design requirements of the product in this example are: a. CD grain effect on the back; b. high-gloss, high-gloss surface effect on the front; c. raised characters on the front. When designing the mold, the CD pattern effect is produced by electroforming on the back, and the high-gloss surface is polished after the characters are produced by EDM on the front to achieve a mirror effect.

[0021] 2. Precise injection molding blank

[0022] Before the injection molding process, the mold should be cleaned without oil or dirt. During the molding process, the injection molding parameters should be adjusted to form qualified products, and the surface should b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com