LDPE(Low-Density Polyethylene) high-foaming sheet and packing material

A packaging material and high-foaming technology, applied in the field of foamed plastics, can solve the problems of poor moisture resistance and light resistance, low strength, affecting tear resistance and cushioning, and achieve the effect of good resilience and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of LDPE high-foaming sheet: mix 90 parts of LDPE granules, 2 parts of talcum powder, 0.008 parts of color masterbatch and 0.008 parts of antistatic agent according to parts by mass, put them into the extruder for melting and kneading; Add 0.5 part of butane and 0.05 part of monoglyceride to the middle part of the machine and continue mixing to obtain a rubber compound; the rubber compound is extruded from the machine head and die, and after cooling, traction, flattening and winding Serve as LDPE high foaming material.

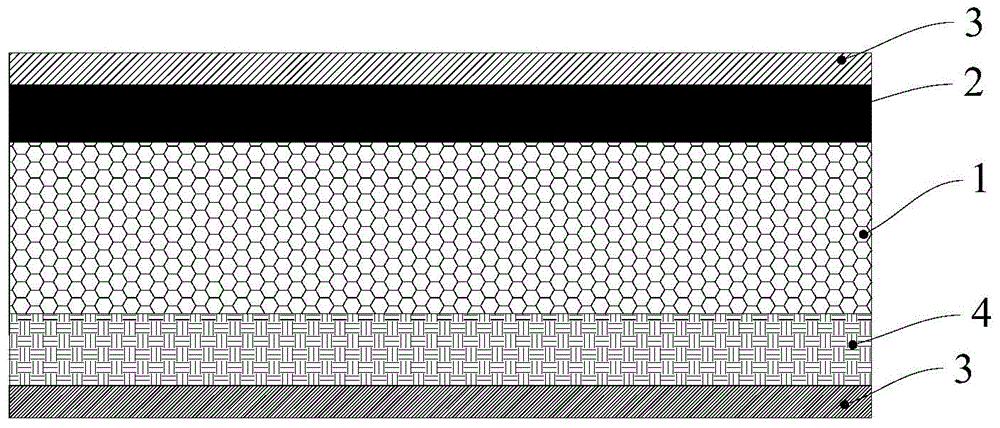

[0034] Preparation of packaging materials: Place the above-mentioned LDPE high-foaming sheet, aluminized film, woven cloth, etc. on the substrate frame, and pull the substrate according to the order of the auxiliary rollers and transmission equipment, and the PE plastic particles are molded by the screw. After melting, it is extruded in a linear form from the die of the flat die head. After high-temperature stretching, it adheres to the surfa...

Embodiment 2

[0036] Except the proportioning of raw materials in the preparation of LDPE high-foaming sheet, other is the same as embodiment 1. In this example, the raw material ratio of LDPE high foaming sheet is 100 parts of LDPE colloidal particles, 5 parts of talcum powder, 2 parts of butane, 0.15 parts of monoglyceride, 0.02 parts of color masterbatch and 0.02 parts of antistatic agent.

Embodiment 3

[0038] Except the proportioning of raw materials in the preparation of LDPE high-foaming sheet, other is the same as embodiment 1. In this example, the raw material ratio of LDPE high foaming sheet is 95 parts of LDPE rubber particles, 3.5 parts of talcum powder, 1 part of butane, 0.1 part of monoglyceride, 0.01 part of color masterbatch and 0.01 part of antistatic agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com