Shell of electronic device and manufacturing method thereof

The technology of an electronic device and manufacturing method is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, and other household appliances. Insufficient strength and bonding precision, etc., to achieve the effect of improving use value and added value, more textured appearance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

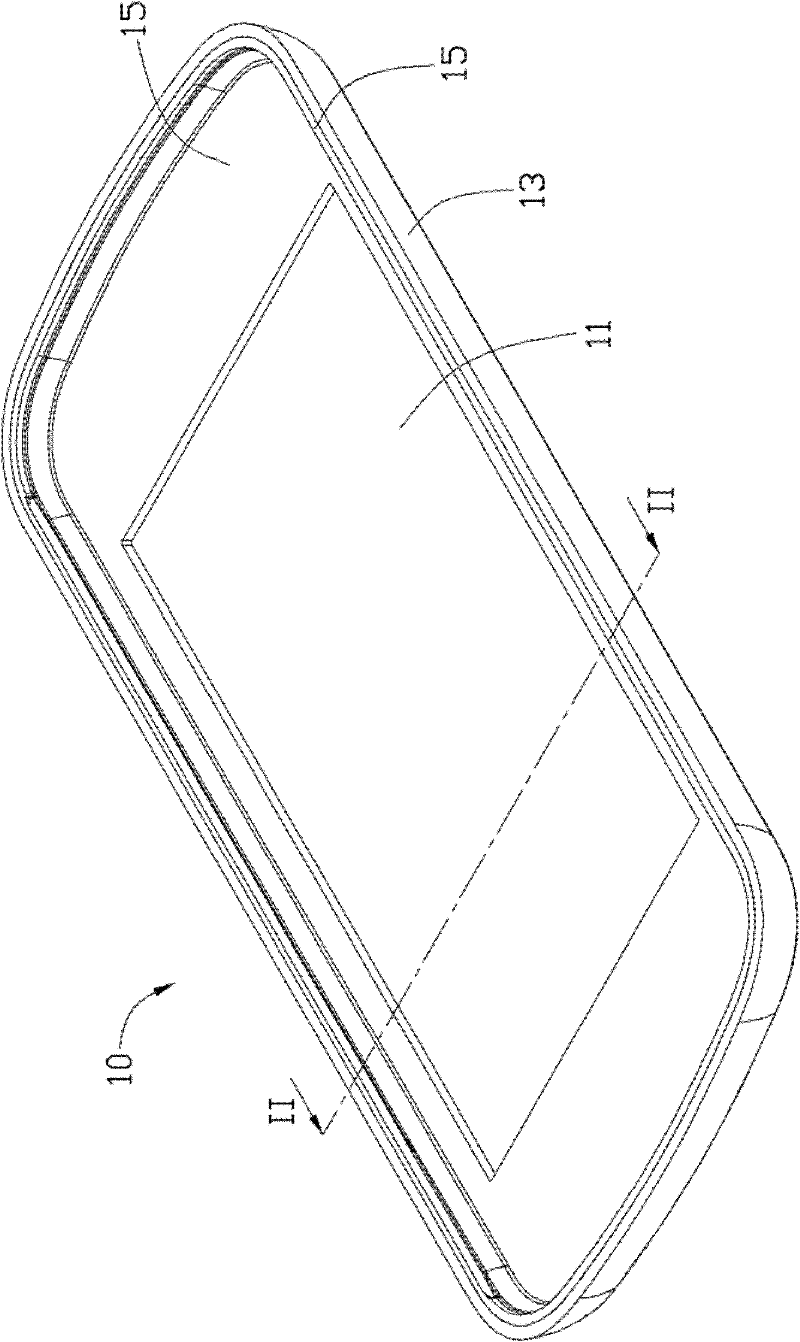

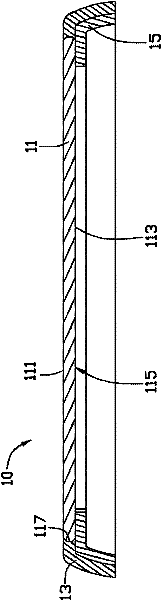

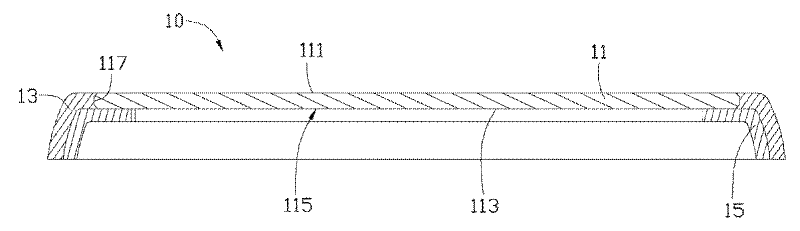

[0024] see figure 1 and figure 2 , the electronic device casing 10 of a preferred embodiment of the present invention includes a window 11, a first casing 13 combined with the window 11, and a window 11 combined with the first casing 13 respectively. The second housing member 15.

[0025] The window member 11 is a transparent glass panel, which includes an outer surface 111 , an inner surface 113 and a side wall 117 . A window portion 115 is formed on the inner surface 113, and the window portion 115 is used for reading information or information displayed on the electronic device. The sidewall 117 is formed as an arc surface. The thickness of the window member 11 is preferably 1.0-1.25mm. This window piece 11 has higher hardness (pencil hardness can reach 6H), and its Young's modulus is 70-75GPa (1×10 9 Pa), the tangential modulus is 30-35GPa. The light transmittance of the window member 11 is above 90%.

[0026] The first housing part 13 is combined with the side wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com