Construction curtain wall ceramic

A coating and curtain wall technology, applied in the field of coating compositions based on inorganic substances, can solve the problems of poor fire resistance and weather resistance, and achieve the best anti-corrosion performance, diverse colors, and wide space effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

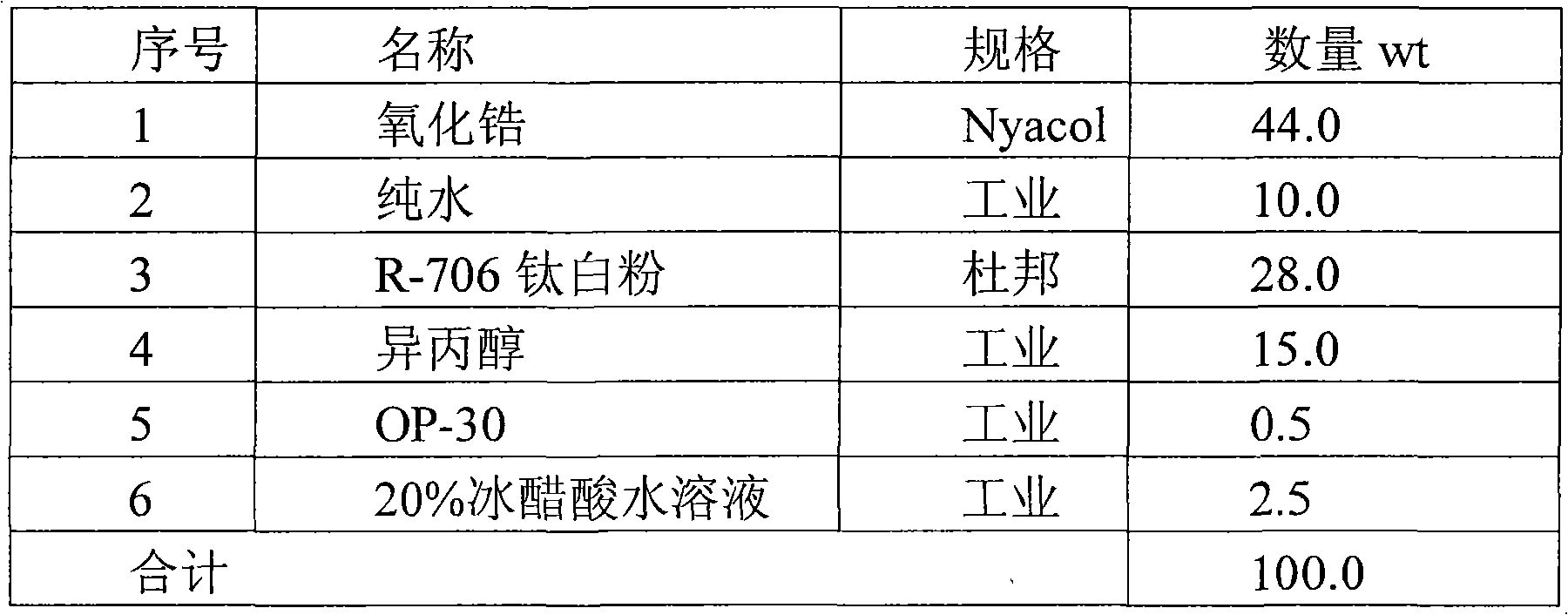

[0046] Component A of white ceramic coating for building curtain wall

[0047]

[0048] Building curtain wall white porcelain coating component B

[0049]

[0050] Among them, KH560 is γ-glycidyl etheroxypropyl trimethoxysilane. The pH value of component A needs to be controlled between 3.5-4.3.

[0051] A component manufacturing process:

[0052] 1. Add material 1 into the container, add material 2, material 5 and material 6 under stirring, and stir evenly.

[0053] 2. Add material 3 and stir evenly.

[0054] 3. Use a sand mill to grind to a fineness of ≤25um.

[0055] 4. Slowly add material 4 under stirring, and mechanically stir evenly.

[0056] B component manufacturing process:

[0057] Add material 1 into the container, slowly add material 2 under stirring, and stir evenly.

[0058] Painting:

[0059] After the aluminum profile is degreased, it is sandblasted with 120 mesh corundum sand (the same below). Mix the above coatings according to A:B=2:1 (weight ra...

Embodiment 2

[0061] Component A of blue ceramic coating for building curtain wall

[0062] serial number

name

Specification

Quantity wt

1

Zirconia

Nyacol

40.0

2

pure water

industry

12.0

3

R-930 titanium dioxide

Ishihara

20.0

4

HD555 cobalt blue

Kaibai

5.0

5

Isopropanol

industry

20.0

6

OP-10

industry

1.0

7

20% acrylic

industry

2.0

[0063] Building curtain wall blue ceramic paint component B

[0064] serial number

name

Specification

Quantity wt

1

Methyltriethoxysilane

to import

60.0-90.0

2

KH-560

to import

10.0-40.0

[0065] A component: B component = 1.5: 1 (weight ratio)

[0066] The performance of the coating film is tested, and the data are as follows:

[0067] Test items

Embodiment 3

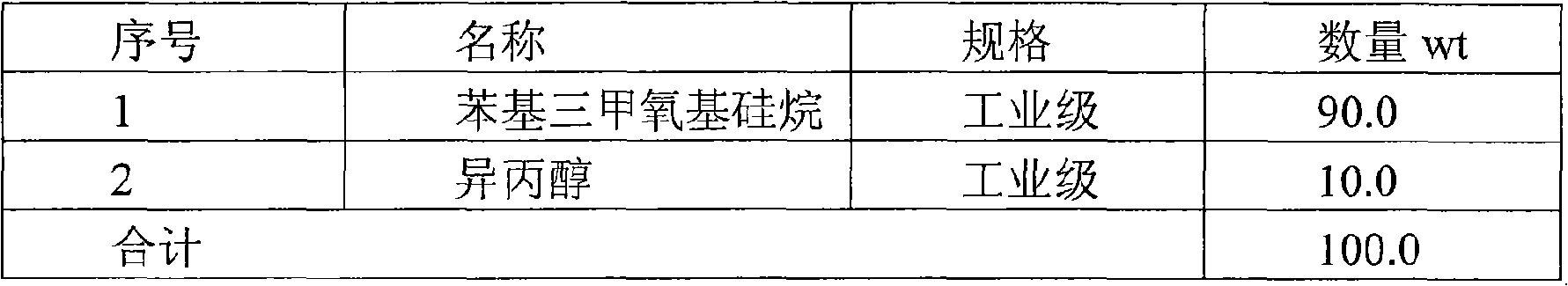

[0069] Component A of building curtain wall red ceramic coating

[0070] serial number

name

Specification

Quantity wt

1

Nyacol

50.0

2

pure water

industry

4.0

3

Tico655

Kaibai

23.0

4

Isopropanol

industry

20.0

5

Kusumoto

1.0

6

Aqueous solution of glacial acetic acid

industry

2.0

[0071] Tico655 in the table is an organic-inorganic composite pigment. The selected nonionic surfactant is polyoxyethylene alkylphenol condensate, and its HLB value is 8-10.

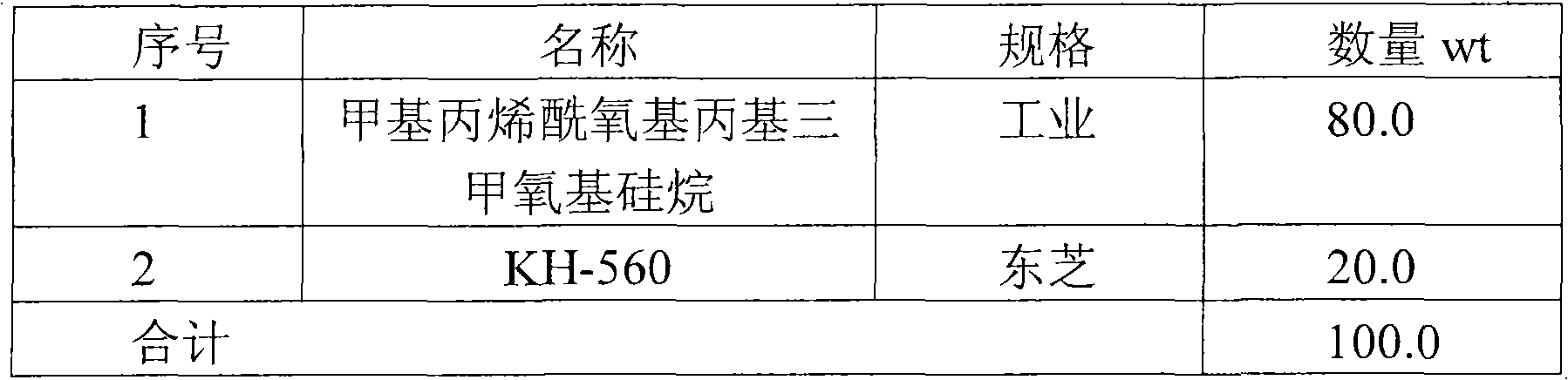

[0072] Component B of building curtain wall red ceramic coating

[0073]

[0074] A component: B component = 3: 1 (weight ratio)

[0075] The performance of the coating film is tested, and the data are as follows:

[0076] Test items

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com