Selenium-rich sweetener and its preparing method

A selenium-enriched sweetening and selenate technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of unacceptable by farmers, the use of fruits and melons, and high prices, and achieve obvious fruit cracking prevention, obvious effects, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

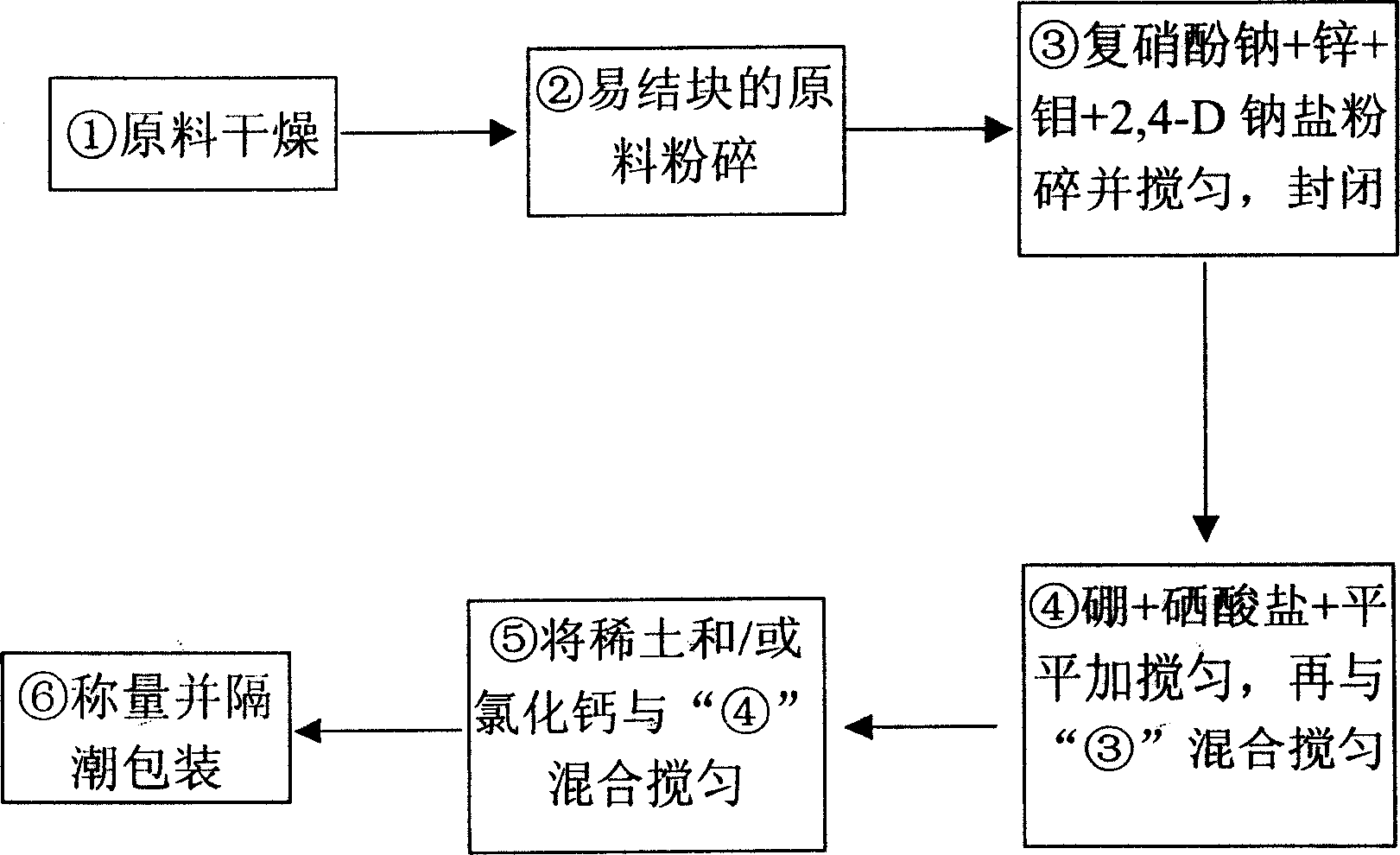

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 (unit: 10 grams, the same below)

[0033] The weight of each component or raw material is as follows (the purchased raw materials are powdery or crystalline):

[0034] Selenic acid 20, sodium nitrophenolate 10, rare earth 20, 2,4-D sodium salt 0.6, Pingpingjia 0.6, ammonium dimolybdate 12.5, zinc sulfate heptahydrate 12.5, borax 23.8.

[0035] In actual operation, the above raw materials are not weighed first, but whichever is used, such as sodium binitrophenolate, zinc sulfate heptahydrate, ammonium dimolybdate and 2,4 -D sodium salt. The weight unit is 10 grams, such as selenic acid 20 (10 grams), the actual weighing is 200 grams.

[0036] ① First, dry the raw materials to be used in the drying room (the so-called drying is generally based on common sense of life and hand feel, and it is mainly for the convenience of the next crushing process).

[0037] In a closed room with a dehumidifier and an air conditioner, that is, the humidity in the room does ...

Embodiment 2

[0045] The weight of each component, i.e. raw material, is as follows:

[0046] Sodium selenate 15, sodium nitrophenolate 6, anhydrous calcium chloride 35, 2,4-D sodium salt 0.5, Pingping 0.5, ammonium tetramolybdate 8.5, zinc sulfate monohydrate 22, boric acid 12.5.

[0047]The preparation method is the same as in Example 1 (only the specific raw materials and rare earths of selenate, molybdenum, zinc, boron have changes: sodium selenate replaces selenic acid, anhydrous calcium chloride replaces rare earth, ammonium tetramolybdate replaces ammonium dimolybdate , zinc sulfate monohydrate replaces zinc sulfate heptahydrate, and boric acid replaces borax), and the product appearance is also with embodiment 1.

Embodiment 3

[0049] The weight of each component, i.e. raw material, is as follows:

[0050] Sodium selenite 18, sodium nitrophenolate 8, rare earth 15, anhydrous calcium chloride 15, 2,4-D sodium salt 0.4, Pingping 0.4, ammonium heptamolybdate 10.2, zinc sulfate monohydrate 16.5, boric acid 16.5.

[0051] Preparation method is the same as embodiment 1 (only the concrete raw material of selenate, molybdenum, zinc, boron and the content of rare earth have change namely: sodium selenite replaces selenic acid, rare earth and anhydrous calcium chloride replace single rare earth, heptamolybdenum Ammonium acid replaces ammonium dimolybdate, zinc sulfate monohydrate replaces zinc sulfate heptahydrate, and boric acid replaces borax), and the product appearance is also with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com