Paint for building curtain wall

A coating and curtain wall technology, applied in the field of inorganic-based coating compositions, can solve the problems of not bright enough color, poor weather resistance, expensive raw materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Building curtain wall white ceramic coating A component

[0046] serial number

name

Specification

Quantity wt

1

Aluminum oxide

Nyacol

44.3

2

pure water

industry

11.1

3

R-706 titanium dioxide

dupont

29

4

Isopropanol

industry

14.83

5

Kusumoto

0.60

6

Auxiliary 2

to import

0.17

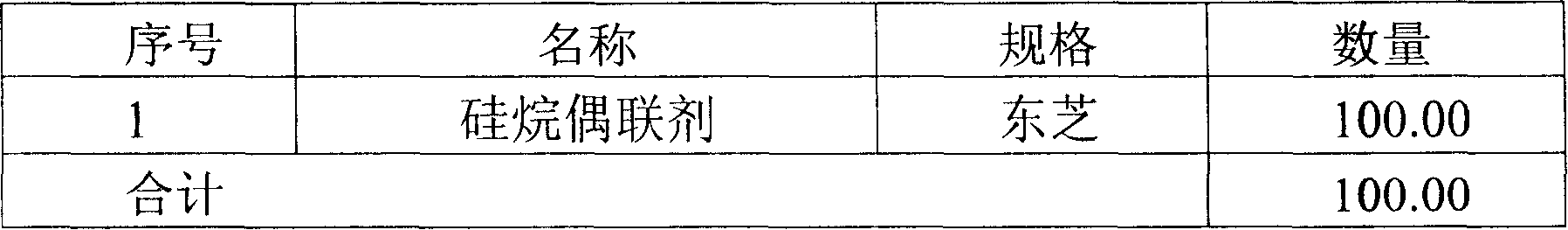

[0047] Building curtain wall white ceramic coating component B

[0048]

[0049] Process:

[0050] 1. Add material 1 into the container, add material 2, material 5 and material 6 under stirring, and stir evenly.

[0051] 2. Add material 3 and stir evenly.

[0052] 3. Grind until the fineness is qualified.

[0053] 4. Slowly add material 4 under stirring, mechanically stir evenly, and check the fineness.

[0054] Painting:

[0055] After the aluminum profile is degreased, it is sandblasted with ...

Embodiment 2

[0060] Embodiment 2 Building curtain wall blue ceramic coating A component

[0061] serial number

name

Specification

quantity

1

Zirconia

Nyacol

20-70

2

pure water

industry

5-30

3

R-930 titanium dioxide

Ishihara

50-10

4

HD555 cobalt blue

Kaibai

10-20

5

Isopropanol

industry

15-30

6

Auxiliary 1

to import

0.60

[0062] Building curtain wall blue ceramic paint component B

[0063] serial number

name

Specification

quantity

1

Organosilicon compound 1

to import

60-90

[0064] 2

Organosilicon compound 2

to import

10-40

[0065] A component: B component = 3:1-1:1 (weight ratio)

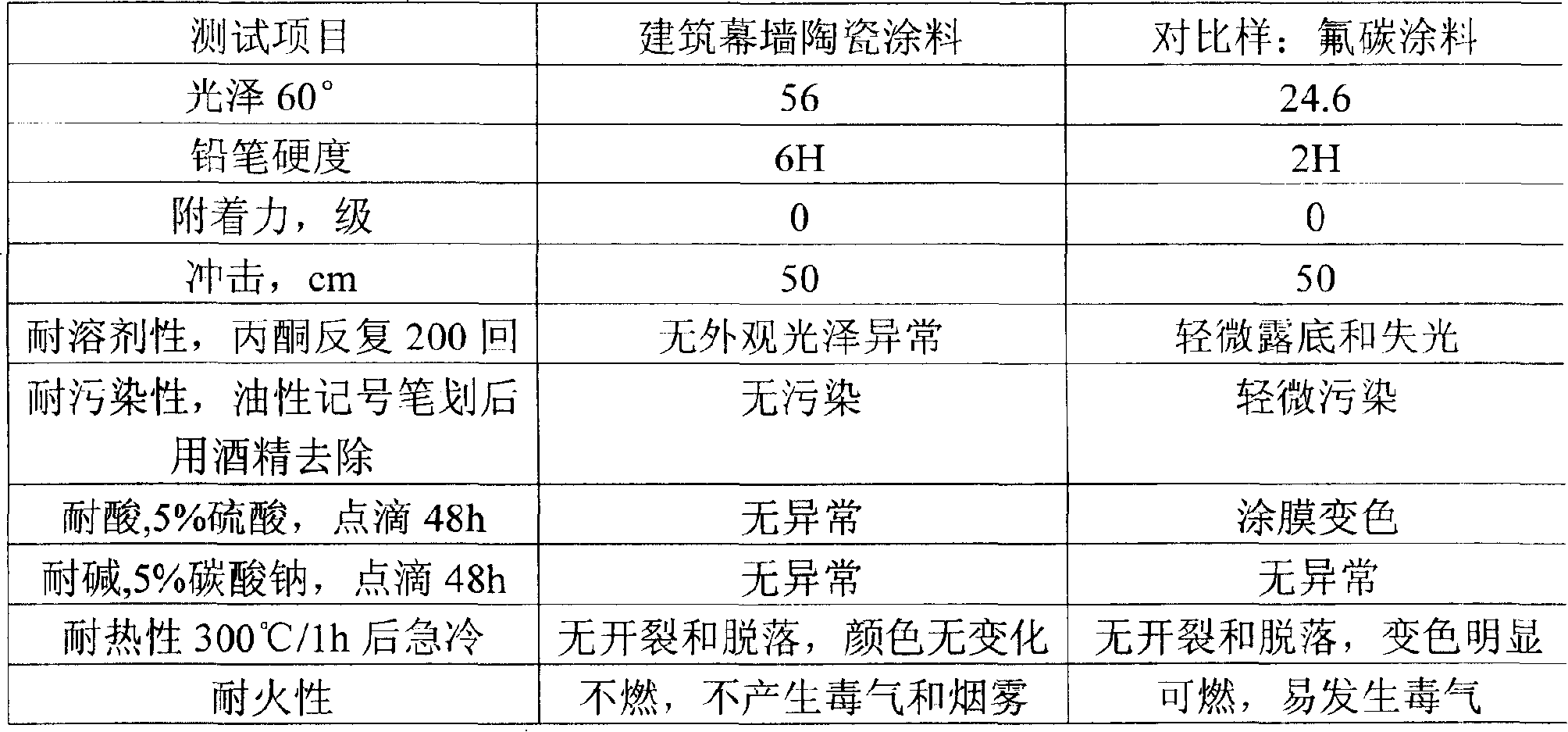

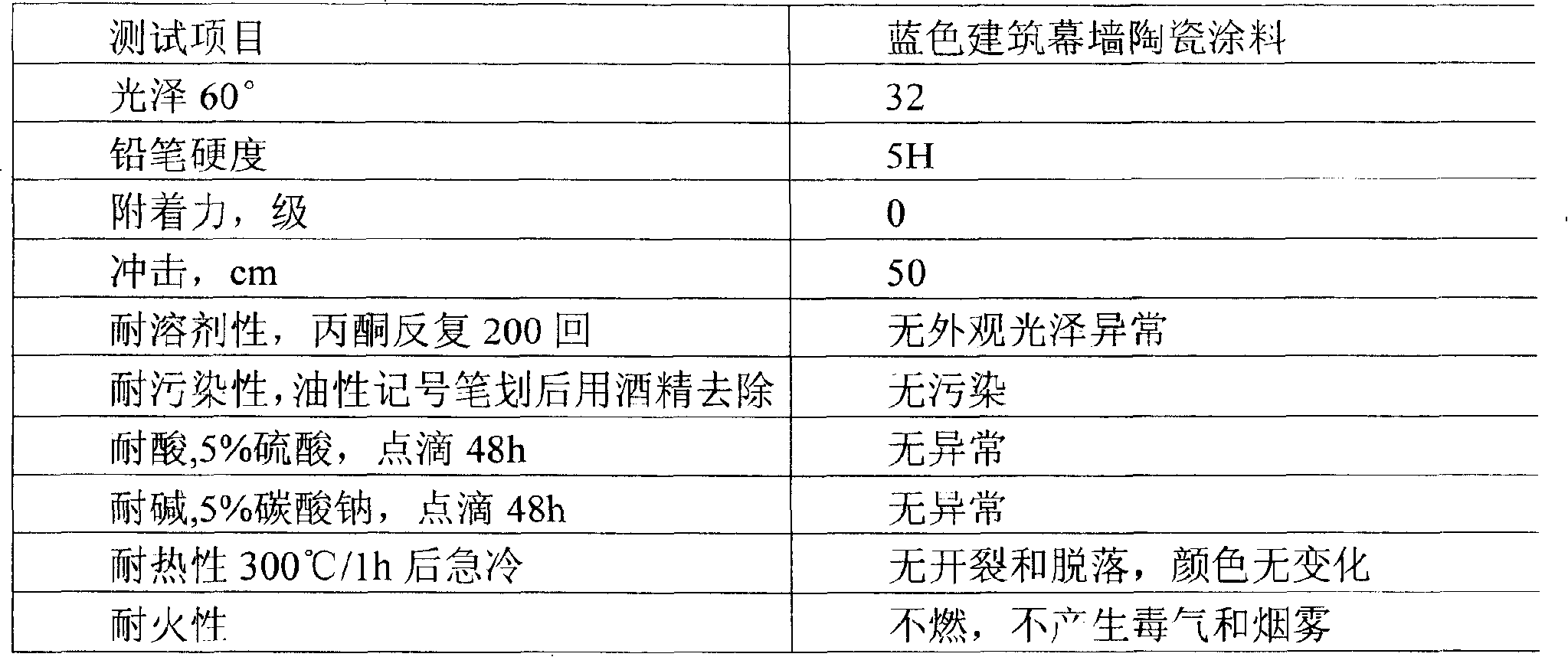

[0066] The performance of the coating film is tested, and the data are as follows:

[0067]

Embodiment 3

[0068] Embodiment 3 building curtain wall red ceramic coating A component

[0069] serial number

name

Specification

quantity

1

Nyacol

20-70

2

pure water

industry

5-30

3

Tico655

Kaibai

10-60

4

Isopropanol

industry

15-30

5

Auxiliary 1

to import

0.60

6

Auxiliary 2

to import

0.17

[0070] Building curtain wall red ceramic paint component B

[0071]

[0072] A component: B component = 3:1-1:1 (weight ratio)

[0073] The performance of the coating film is tested, and the data are as follows:

[0074]

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com