New process for producing multi-layer composite high-elasticity rubber hoses

A production process, multi-layer composite technology, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of tear resistance, fatigue resistance and poor safety, poor product quality consistency, breaking and hurting people, etc. Fatigue performance and safety are improved, the color of the adhesive layer can be changed, and the effect of strong fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

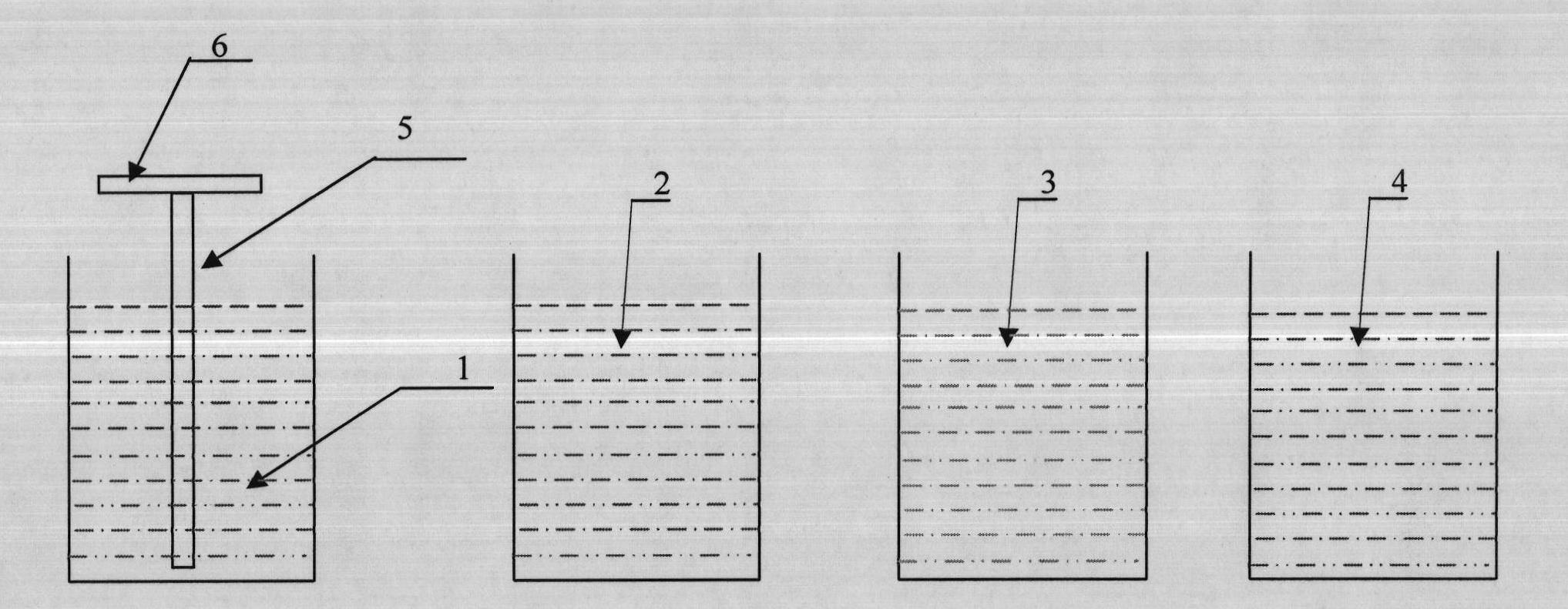

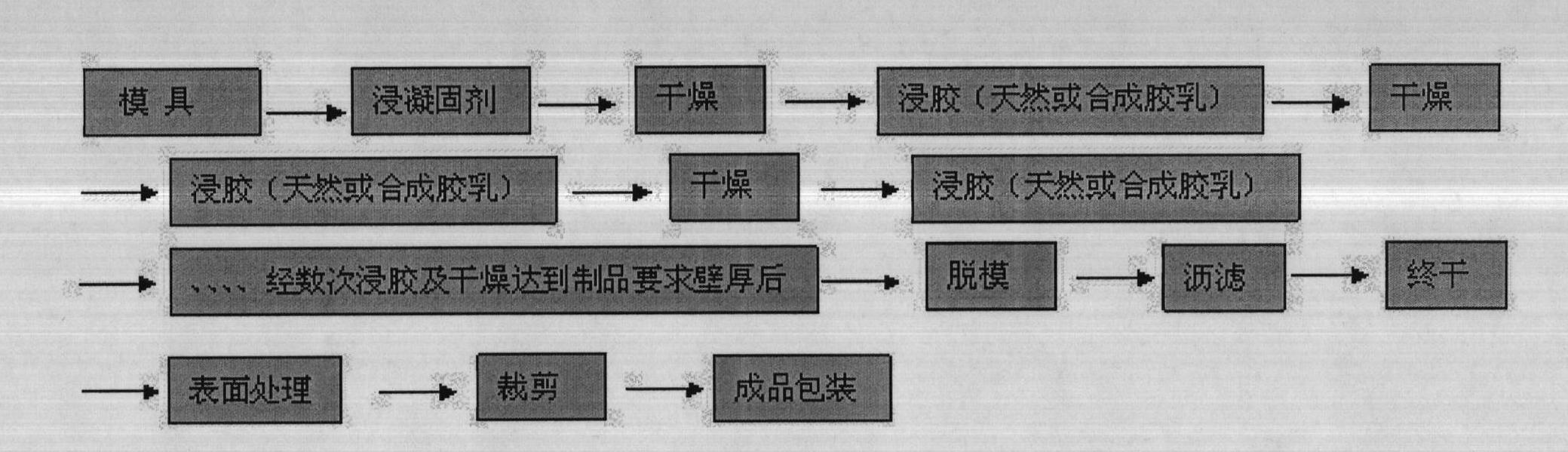

[0037] Three-layer composite hose, see figure 1 and image 3 , produced by a simple production process.

[0038] For the specific rubber hose manufacturing device, see figure 1 , process flow image 3 . Immerse the cylindrical stainless steel mold 5 (also can be other metals, plastics, rubber etc.) that handle or formwork 6 has been installed in the calcium chloride aqueous solution tank 1 of 35% w / w for 10 seconds, slowly mention, Dry in an oven at 105°C for 3 minutes, cool to room temperature, then slowly insert natural rubber latex or synthetic latex with a concentration of 50% w / w mixed with blue color paste and vulcanizing agent into tank 2 for 10 seconds, then slowly Slowly lift the mold, turn it slowly for 20 seconds, put it in a 90°C oven to dry for 3 minutes, take it out and cool it to room temperature, and the three-layer composite rubber hose can be completed Figure 5The first layer of blue film①. This mold with the first layer of adhesive film is put into th...

Embodiment 2

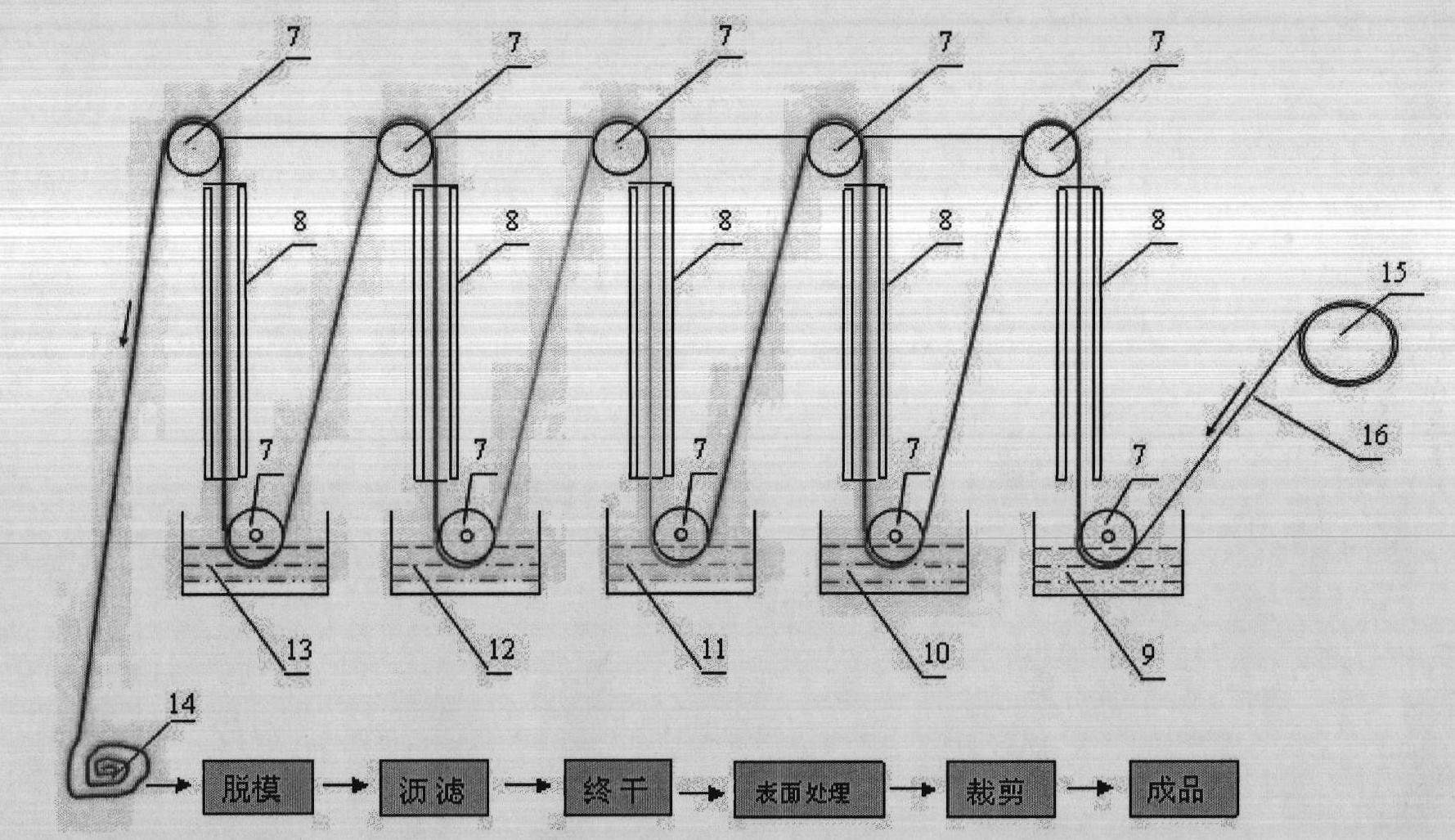

[0041] Four-layer nano-reinforced composite hose, see figure 2 and image 3 , produced by a continuous production process.

[0042] First select the bundled flexible cylindrical rubber strip 16 according to the inner diameter of the rubber hose product, press image 3 The process is first assembled on the production line. Tank 9 is loaded with a calcium chloride aqueous solution coagulant with a concentration of 30% w / w; tank 10 is filled with natural rubber latex or synthetic latex with a concentration of 50% w / w of green color paste and vulcanizing agent; tank 11 is loaded with Cooperate with the natural rubber latex or synthetic latex that the concentration of yellow color paste, vulcanizing agent and nano-calcium carbonate particle is 50%w / w; Tank 12 is filled with the concentration that is equipped with blue color paste, vulcanizing agent and nano-calcium carbonate particle is 50% Natural latex or synthetic latex of w / w; Groove 13 is filled with the concentration of 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com