Molded stone architectural product having a foam core

a technology of foam core and molded stone, which is applied in the direction of ceramic shaping apparatus, building components, constructions, etc., can solve the problems of heavy natural stone, limited use of natural stone, and high cost of natural stone, and achieve the effect of better suppor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

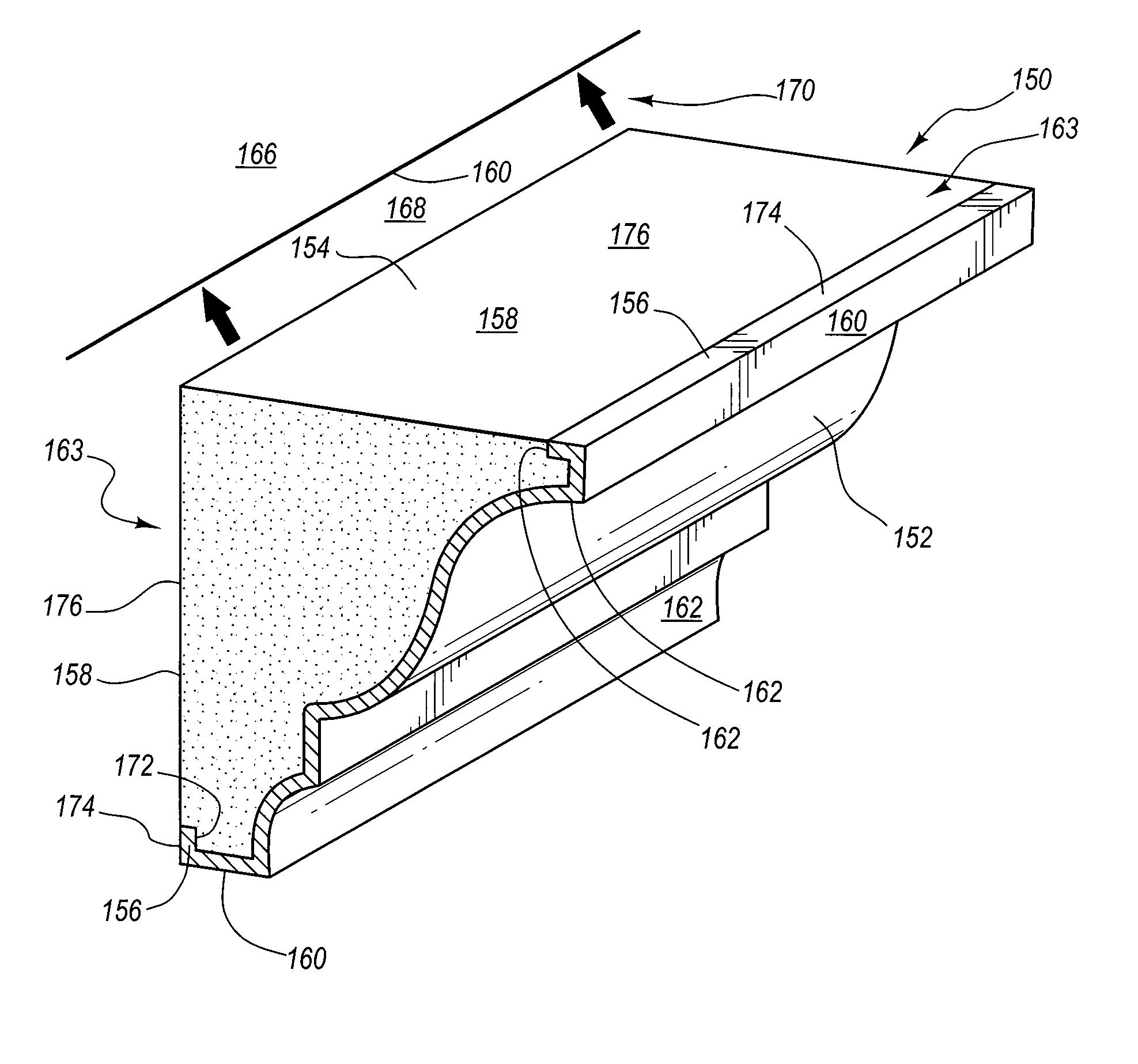

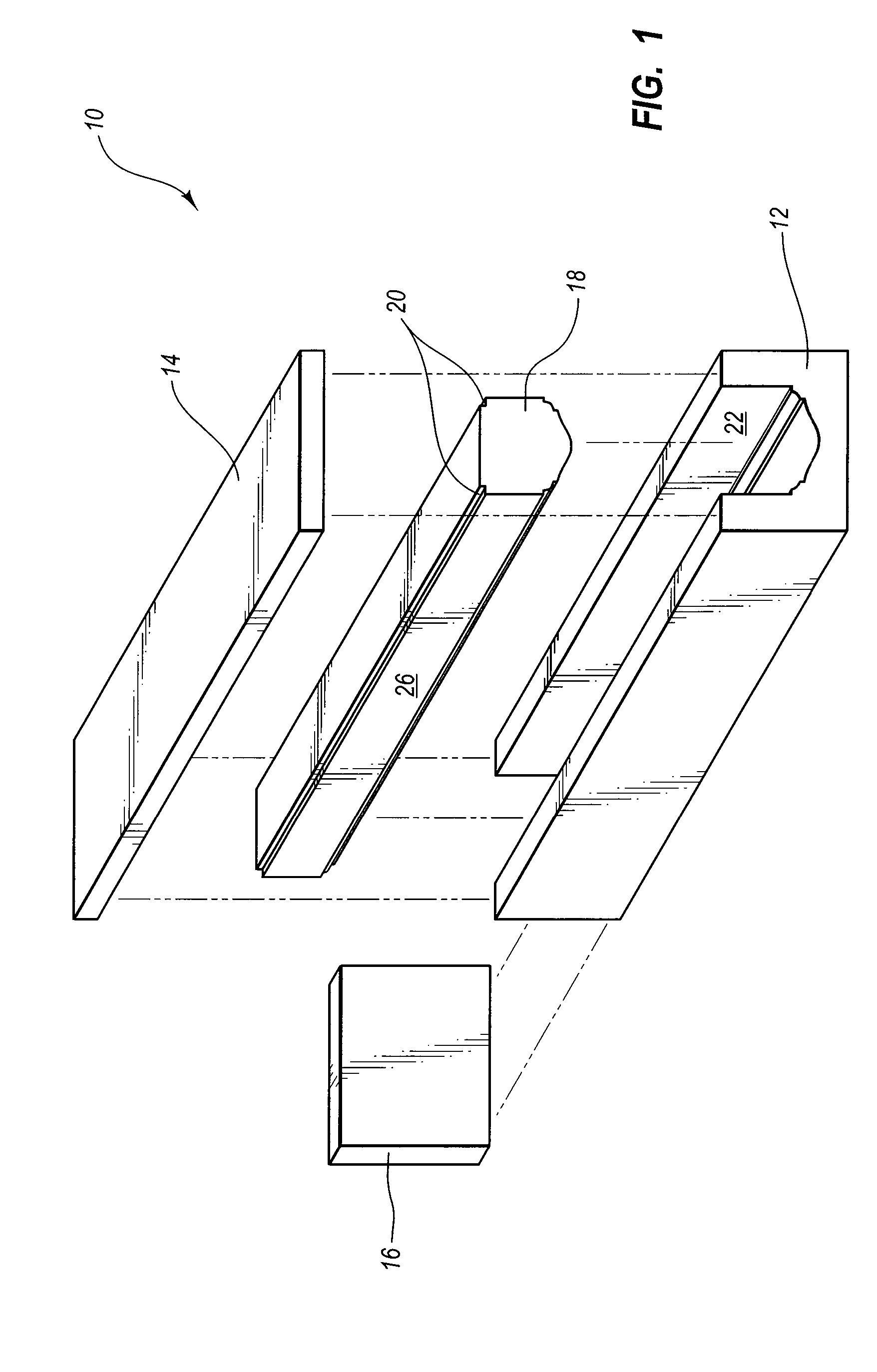

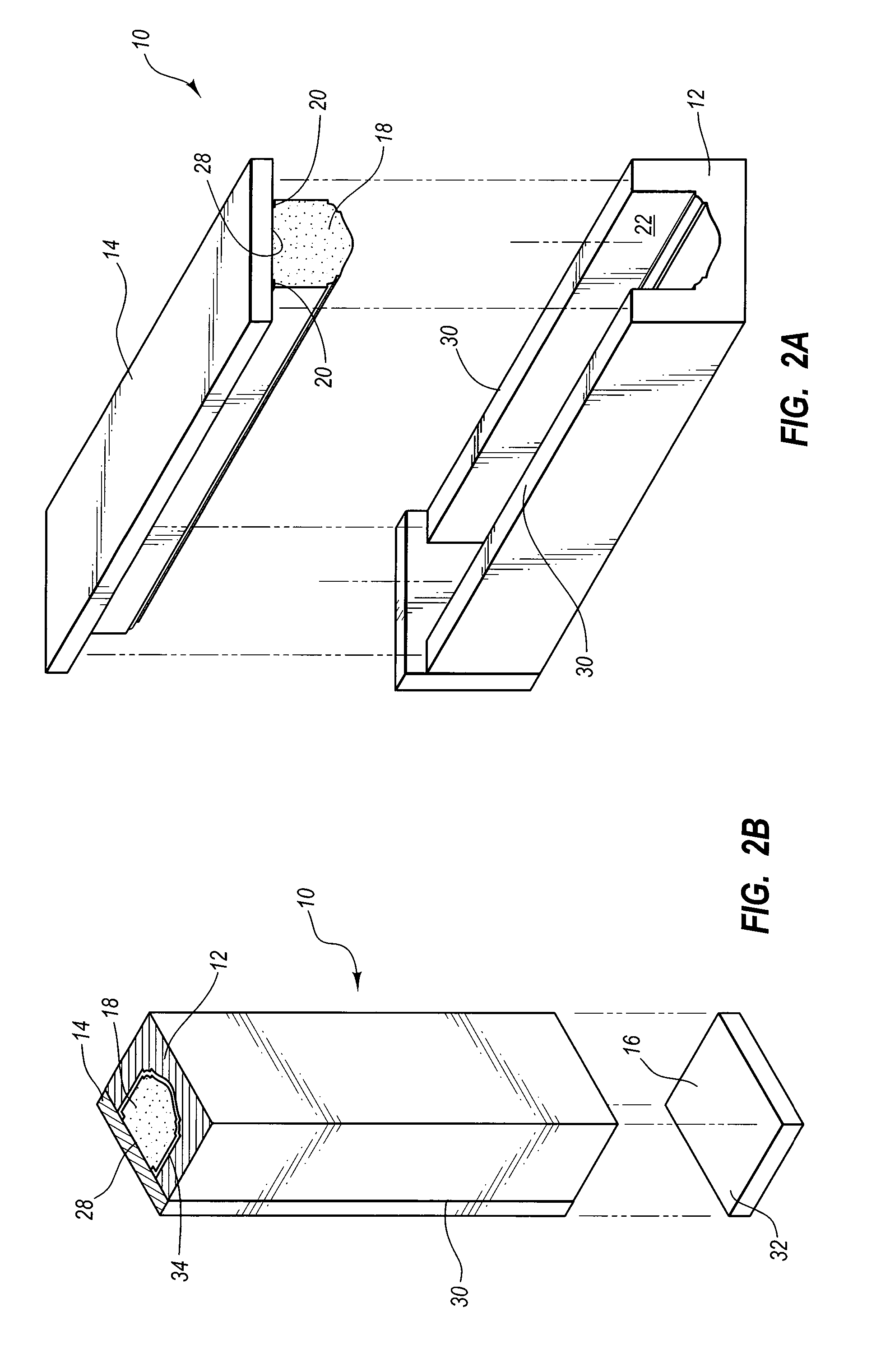

[0005] The present invention has been developed in response to the present state of the art, and in particular, in response to the problems and needs in the art that have not yet been fully solved by currently available architectural stone products. The present invention relates to a method of preparing a mold which is used to manufacture architectural cast stone products containing a foam core. As used herein, an architectural cast stone product is a three dimensional decorative and / or functional structure that is intended to have a stone-like appearance for exterior or interior applications. Examples of architectural cast stone products include but are not limited to columns, caps, bases, balustrades, barrel vaulting, window sills, crown molding, wall caps, keystones, fireplace mantles, column caps and bases, moldings around doors, wall caps, trim stones, quoins, and door and window surrounds.

[0006] The architectural cast stone product of the invention may include a foam core and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com