After-treatment method for cashmere water ripple panne velvets

A water ripple and post-finishing technology, which is applied in the processing of textile materials, continuous processing of textile materials, fiber treatment, etc., can solve problems such as dull hand feeling, uneven water ripples, uniformity of suede surface, etc., and achieve good hygroscopicity And air permeability, soft and bright natural luster, suede plump effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

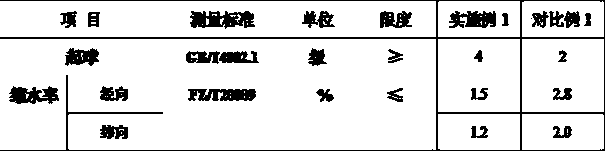

Embodiment 1

[0018] Use pure cashmere as raw material (average diameter 13-17 μm, average length 35mm) to prepare cashmere silk scarves according to the existing technology, and carry out the finishing process according to the following process steps: gray fabric inspection→repair→overlapping→washing→dehydration →Primary shrinking→rinsing→dehydration→secondary shrinking→rinsing→dehydration→drying→intermediate inspection→steel wire fluffing→water softening→water rolling→thorn fruit pulling→rolling storage→drying→shearing→steaming→inspection → Finished product. Wherein, the solution used for washing is an aqueous solution containing 0.1wt% fatty alcohol sulfate sodium salt and 0.1wt% sodium alkylsulfonate, the cleaning temperature is 30-40°C, and the cleaning time is 10-15 minutes; Rinse afterward for 5 minutes. The solution used for one shrinkage contains: 1wt% penetrant JFC, 8wt% octadecyl sulfosuccinate, 7wt% fatty alcohol phosphate, 3wt% crosslinking agent CS-260 and pH regulator NaOH,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com