A kind of making method of linen cotton chenille jacquard fabric

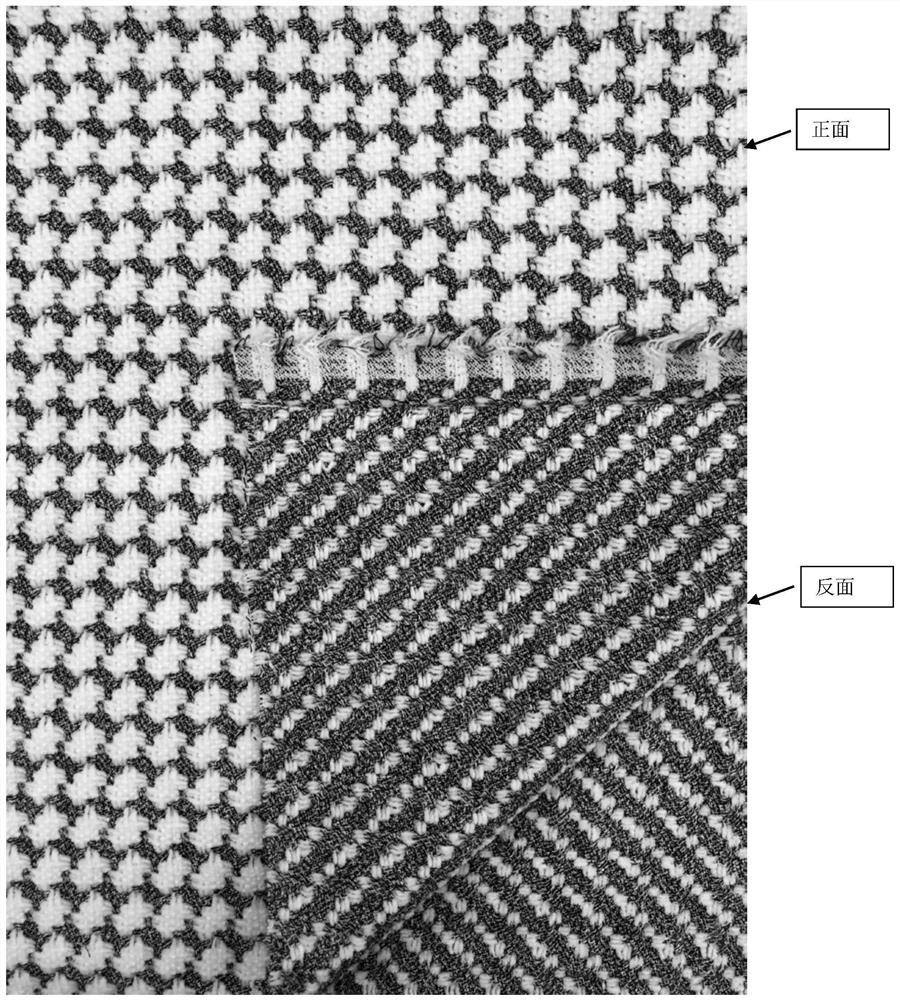

A production method, the technology of flax cotton, which is applied in the direction of digging fabrics, textiles, textiles and papermaking, etc., can solve the problems of poor velvet feeling, hard hand feeling of flax chenille yarn, poor stability, etc., and achieve full suede surface, antibacterial Good air permeability, soft and comfortable feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

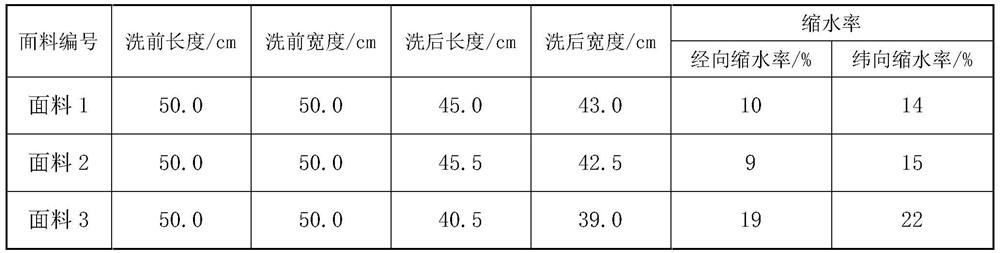

Embodiment 1

[0031] This embodiment relates to a kind of preparation method of linen cotton chenille jacquard fabric;

[0032] Hemp cotton yarn is used as feather yarn, and cotton yarn is used as core yarn to make hemp cotton chenille yarn. Wherein feather yarn adopts the hemp cotton yarn of 21s, and core yarn adopts the full cotton strand of 32s / 2, and the 4.5N hemp cotton chenille yarn that makes is called A yarn (roving) in the present invention;

[0033] The fabric design warp of this embodiment adopts 21s / 2 hemp cotton ab yarn (B yarn) and 4.5N hemp cotton chenille yarn (A yarn), and the weft yarn adopts 21s / 2 hemp cotton ab yarn (B yarn) and 4.5N hemp cotton Cotton chenille yarn (A yarn), the warp yarn density is designed to be 45 yarns / inch, and the weft yarn density is designed to be 51 yarns / inch.

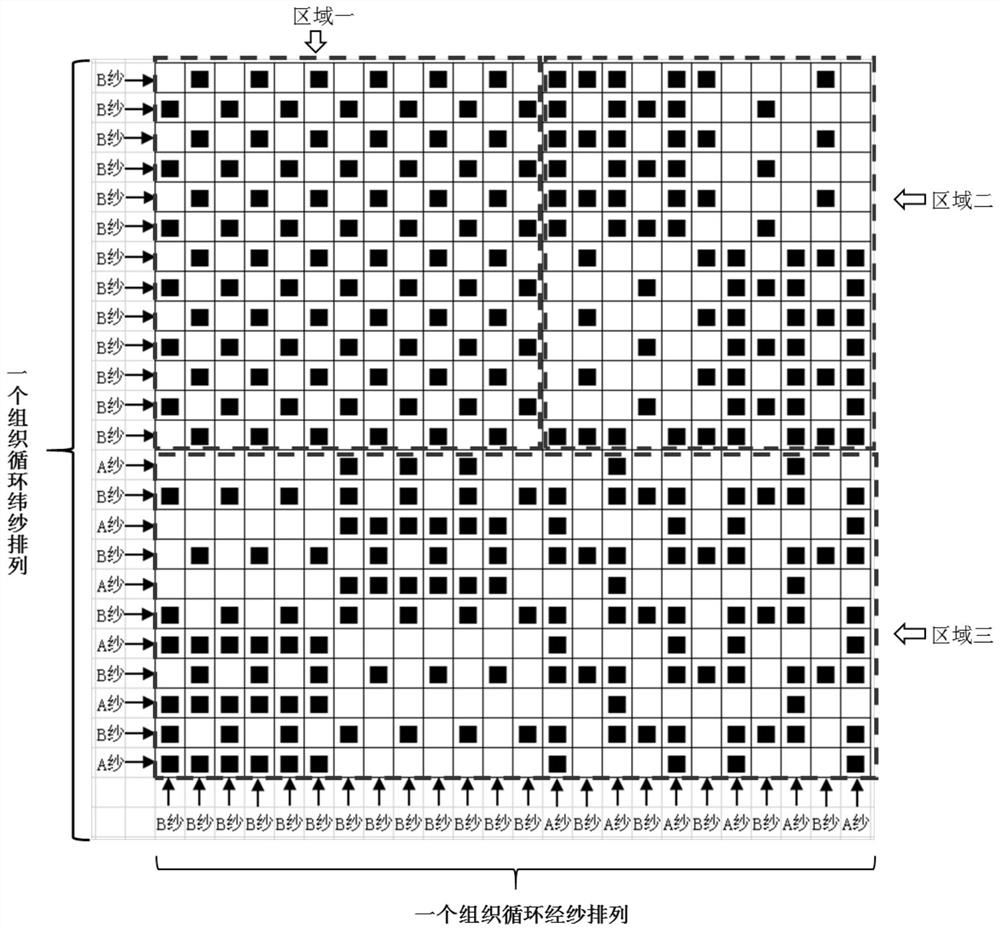

[0034] In this embodiment, delicate dobby weave is added to fabric weave design, and warp and weft yarns (thick and thin yarns) are designed according to a certain arrangement method ...

Embodiment 2

[0046] Present embodiment relates to a kind of preparation method of linen cotton chenille jacquard fabric, basically with embodiment 1, difference is:

[0047] 1. In the preparation of hemp cotton chenille yarn, the chenille core yarn is made of 32s / 2 cotton strands, and the feather yarn is made of 16s hemp cotton yarn. After the core yarn is twisted, the feather yarn is sandwiched between the two. It is set to 600 twist / m, the feather yarn clamping distance is set to 0.35mm, and the feather yarn axial density is 28 / cm, and flax cotton chenille yarn is spun on the chenille spinning machine; the hemp cotton chenille yarn produced The Seoul yarn also does not need to be softened, and it is soft to the touch and has a good velvet feel.

[0048] 2. In the weave and yarn arrangement design of the hemp cotton chenille fabric, the B yarn adopts 16s / 2 hemp cotton ab yarn.

Embodiment 3

[0050] Present embodiment relates to a kind of preparation method of linen cotton chenille jacquard fabric, basically with embodiment 1, difference is:

[0051] In the preparation of hemp cotton chenille yarn, the chenille core yarn adopts 32s / 2 cotton strands, the feather yarn adopts 32s hemp cotton yarn, the chenille core yarn adopts 32s / 2 cotton strands, and the feather yarn adopts For 32s hemp cotton yarn, the core yarn is twisted and the feather yarn is sandwiched between two yarns. The twist is set to 900 twists / m, the feather yarn clamp distance is set to 0.48mm, and the feather yarn axial density is 35 yarns / cm. The linen cotton chenille yarn is spun on the machine; the produced linen cotton chenille yarn also does not need to be softened, and it feels soft and has a good velvet feel.

[0052] 2. In the weave and yarn arrangement design of the hemp cotton chenille fabric, the B yarn adopts 32s / 2 hemp cotton ab yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com