Antibacterial antistatic foamed elastomer material and preparation method thereof

An elastomer material, anti-static technology, applied in the field of foamed elastic materials, can solve the problems of bacteria breeding, poor long-term performance, poor dispersion of antibacterial agents, etc., and achieve excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

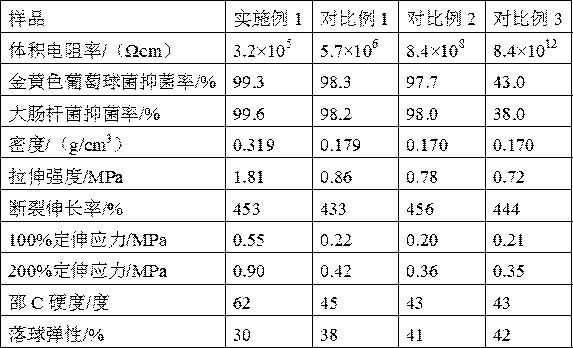

Examples

Embodiment 1

[0020] The embodiment of the present invention provides a preparation method of an antibacterial quaternary phosphonium salt modified tin antimony oxide conductive filler and a hybrid EVA foamed elastomer thereof. It includes the following steps:

[0021] (1) Weigh 15g of nano-antimony tin oxide, heat at 60°C for 4 hours, dry, and grind to obtain antimony tin oxide powder (average particle size 0.05 μm);

[0022] (2) Mix 100g of dodecyloxymethyltributylphosphorous chloride and 0.15g of polyvinyl alcohol into an aqueous solution with a concentration of quaternary phosphonium salt of 4mg / mL, and place tin antimony oxide in it to absorb to saturation (quaternary phosphonium Salt is kept in excess), filtered, heated at 60°C for 4 hours, dried, and ground to obtain quaternary phosphonium salt modified tin antimony oxide conductive filler;

[0023] (3) Then add a solution of 1.5 g of vinyl triperoxy-tert-butylsilane and 30 g of ethanol (the mass ratio of silane to quaternary phosph...

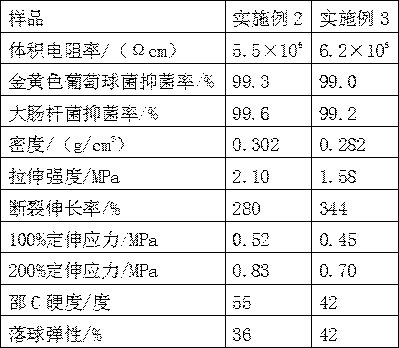

Embodiment 2

[0027] The embodiment of the present invention provides a preparation method of an antibacterial quaternary phosphonium salt modified tin antimony oxide conductive filler and a hybrid EVA foamed elastomer thereof. It includes the following steps:

[0028] (1) Weigh 15g of nano-antimony tin oxide, heat and dry at 60°C for 4 hours, and obtain tin antimony oxide powder after grinding;

[0029] (2) Weigh 100g of tetradecyltributylphosphorus chloride and 0.25g of polyvinyl alcohol to prepare an aqueous solution with a concentration of quaternary phosphonium salt of 4mg / mL, and place tin antimony oxide in it to absorb to saturation (quaternary phosphonium salt keeps Excessive amount), after filtering, fully wash with deionized water, heat at 60°C for 4 hours, dry, and grind to obtain quaternary phosphonium salt modified tin antimony oxide conductive filler;

[0030] (3) Then add a solution mixed with 1.5g of titanate coupling agent and 30g of ethanol (the mass ratio of titanate to ...

Embodiment 3

[0034] The embodiment of the present invention provides a preparation method of an antibacterial quaternary phosphonium salt modified tin antimony oxide conductive filler and a hybrid EVA foamed elastomer thereof. It includes the following steps:

[0035] (1) Weigh 15g of nano-antimony tin oxide, heat and dry at 60°C for 4 hours, and obtain tin antimony oxide powder after grinding;

[0036] (2) According to the mass ratio of polyquaternary phosphonium salt / polyvinyl alcohol = 100 / 0.45, prepare an aqueous solution of polyquaternary phosphonium salt with a concentration of 6 mg / mL, and place tin antimony oxide in it to absorb to saturation (keep the excess of quaternary phosphonium salt) , after filtering, fully wash with deionized water, heat and dry at 60°C for 4 hours, and grind to obtain polyquaternary phosphonium salt modified tin antimony oxide conductive filler;

[0037] (3) Then add the solution mixed with aluminate coupling agent / ethanol=5 / 100 mass ratio (the mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com