High-efficiency heavy metal adsorption and antibacterial nanofiber membrane and preparation method thereof

A nanofiber membrane, heavy metal technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing and other directions, can solve problems such as hidden dangers in life, and achieve the effect of large contact area, uniform fiber size, excellent antibacterial and heavy metal adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

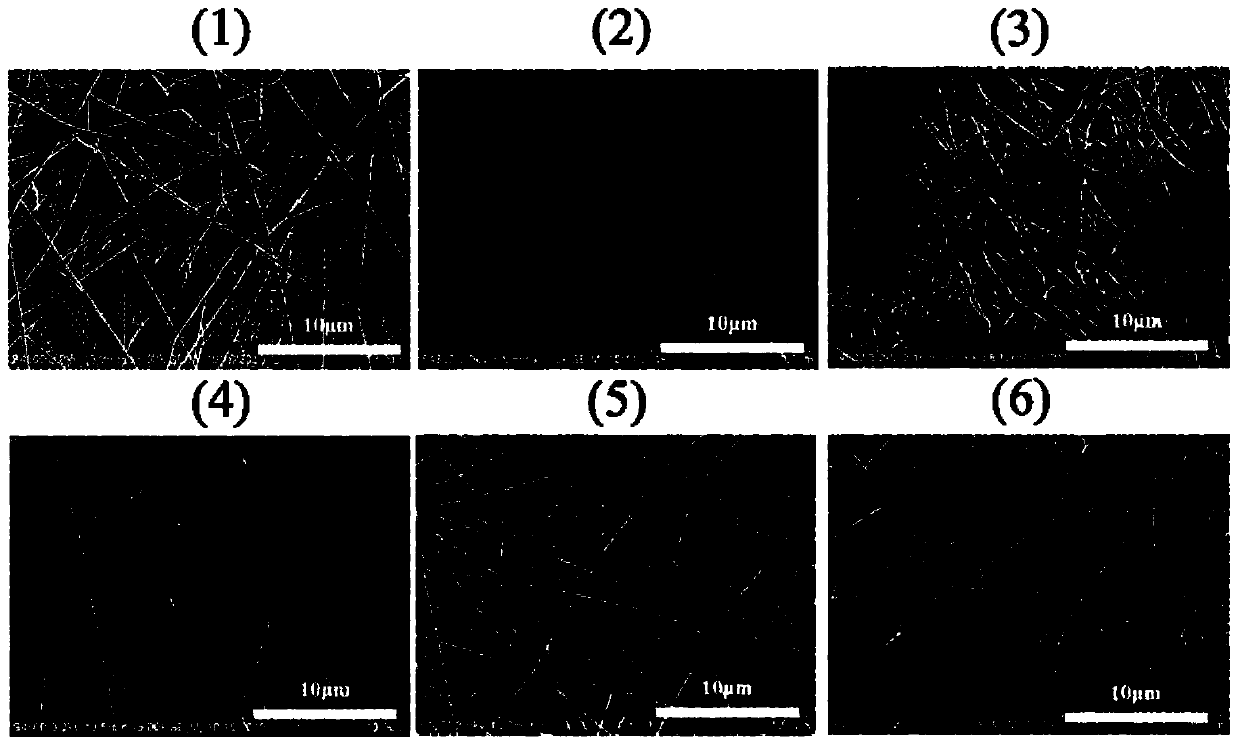

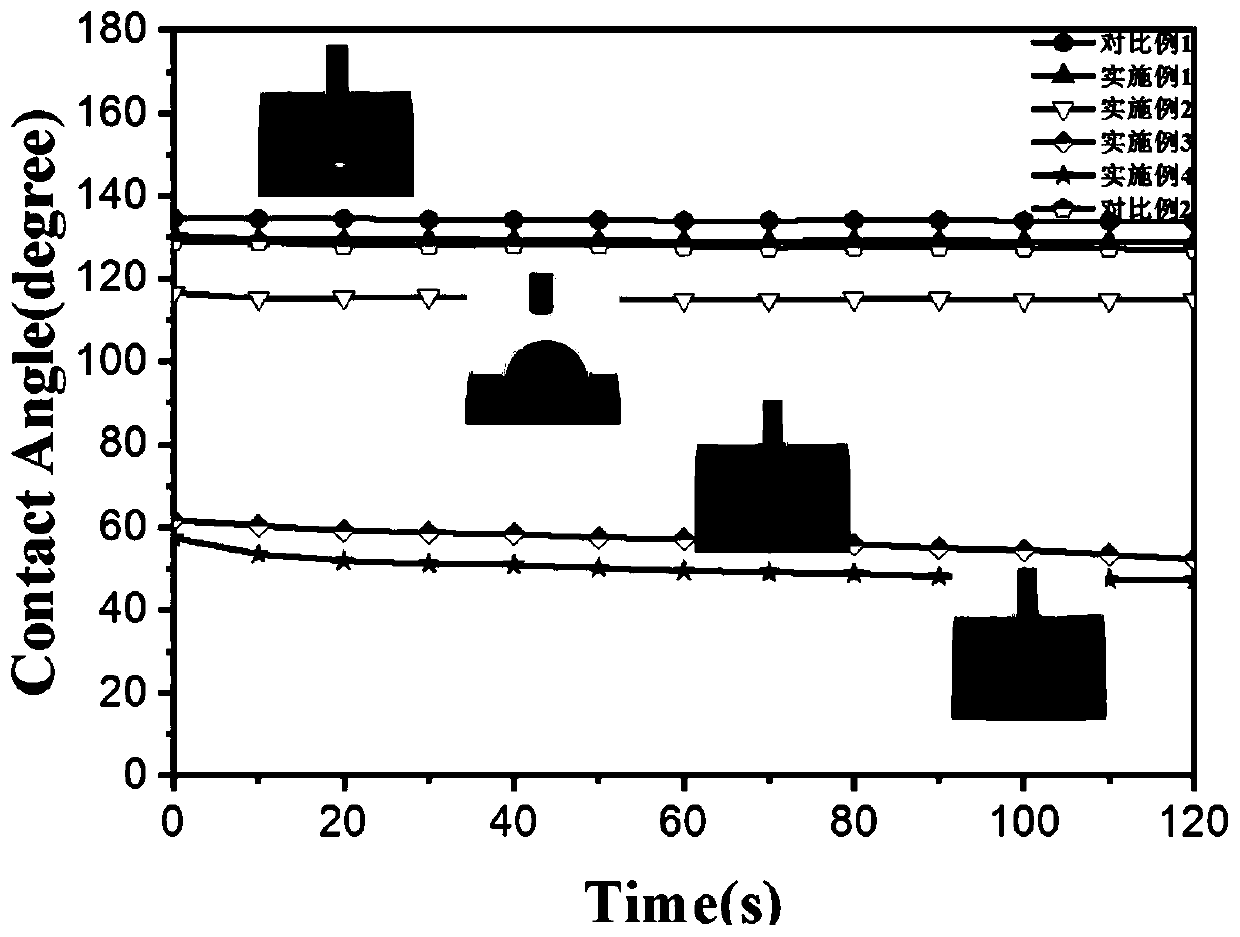

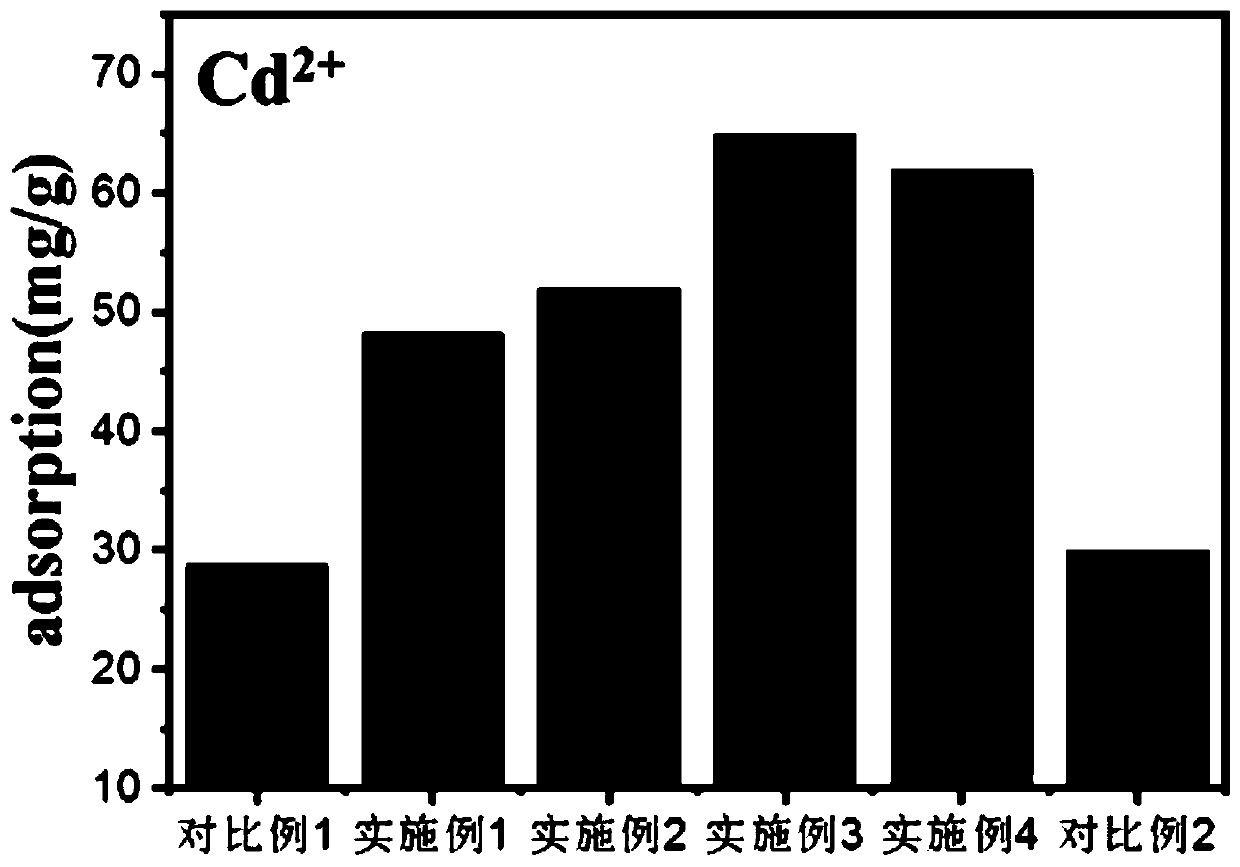

[0031] Step (1) First, 9.8g of PES and 0.2g of 1-vinyl-3-butylimidazolium tetrafluoroborate were added to the reaction kettle at a temperature of 60°C, and the solution was blended for 6h; then, the solution was cooled to At room temperature, pour it into a PTFE mold to lay the film, volatilize the solvent on the obtained film, dry it in vacuum for 24 hours, and irradiate it at room temperature under the irradiation dose of 30kGy in Co-γ irradiation.

[0032] Step (2) Soxhlet extraction of the grafted blend obtained by the above irradiation with methanol for 24 hours, vacuum drying, and preparation of a solution with a concentration of 30%, and then preparing the nanofiber membrane by electrospinning the solution. Denoted as 2wt%-PES nanofiber membrane.

Embodiment 2

[0034] Step (1) First, 9.6g of PES and 0.4g of 1-vinyl-3-butylimidazolium tetrafluoroborate were added to the reaction kettle at a temperature of 60°C, and the solution was blended for 6h; then, the solution was cooled to At room temperature, pour it into a PTFE mold to lay the film, volatilize the solvent on the obtained film, dry it in vacuum for 24 hours, and irradiate it at room temperature under the irradiation dose of 30kGy in Co-γ irradiation.

[0035] Step (2) Soxhlet extraction of the grafted blend obtained by the above irradiation with methanol for 24 hours, vacuum drying, and preparation of a solution with a concentration of 30%, and then preparing the nanofiber membrane by electrospinning the solution. Denoted as 4wt%-PES nanofiber membrane.

Embodiment 3

[0037] Step (1) First, 9.4g of PES and 0.6g of 1-vinyl-3-butylimidazolium tetrafluoroborate were added to the reaction kettle at a temperature of 60°C, and the solution was blended for 6h; then, the solution was cooled to At room temperature, pour it into a PTFE mold to lay the film, volatilize the solvent on the obtained film, dry it in vacuum for 24 hours, and irradiate it at room temperature under the irradiation dose of 30kGy in Co-γ irradiation.

[0038] Step (2) Soxhlet extraction of the grafted blend obtained by the above irradiation with methanol for 24 hours, vacuum drying, and preparation of a solution with a concentration of 30%, and then preparing the nanofiber membrane by electrospinning the solution. Denoted as 6wt%-PES nanofiber membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com