Antibacterial silk product with nano-copper and preparation method of antibacterial silk product with nano-copper

A nano-copper and silk technology, applied in textiles and papermaking, biochemical fiber treatment, enzyme/microbial biochemical treatment, etc., can solve problems such as low adhesion, poor bonding fastness, and restrictions on application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

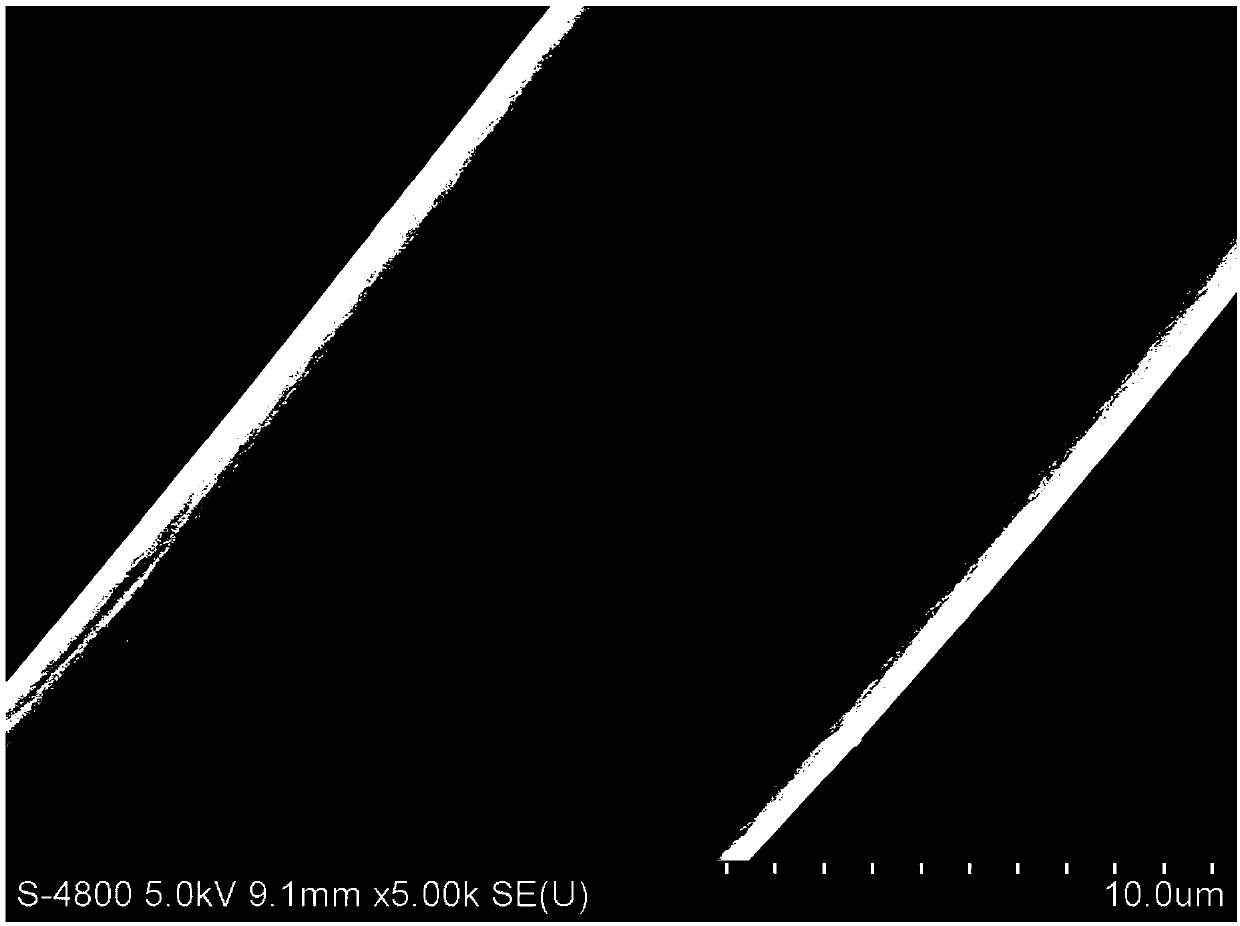

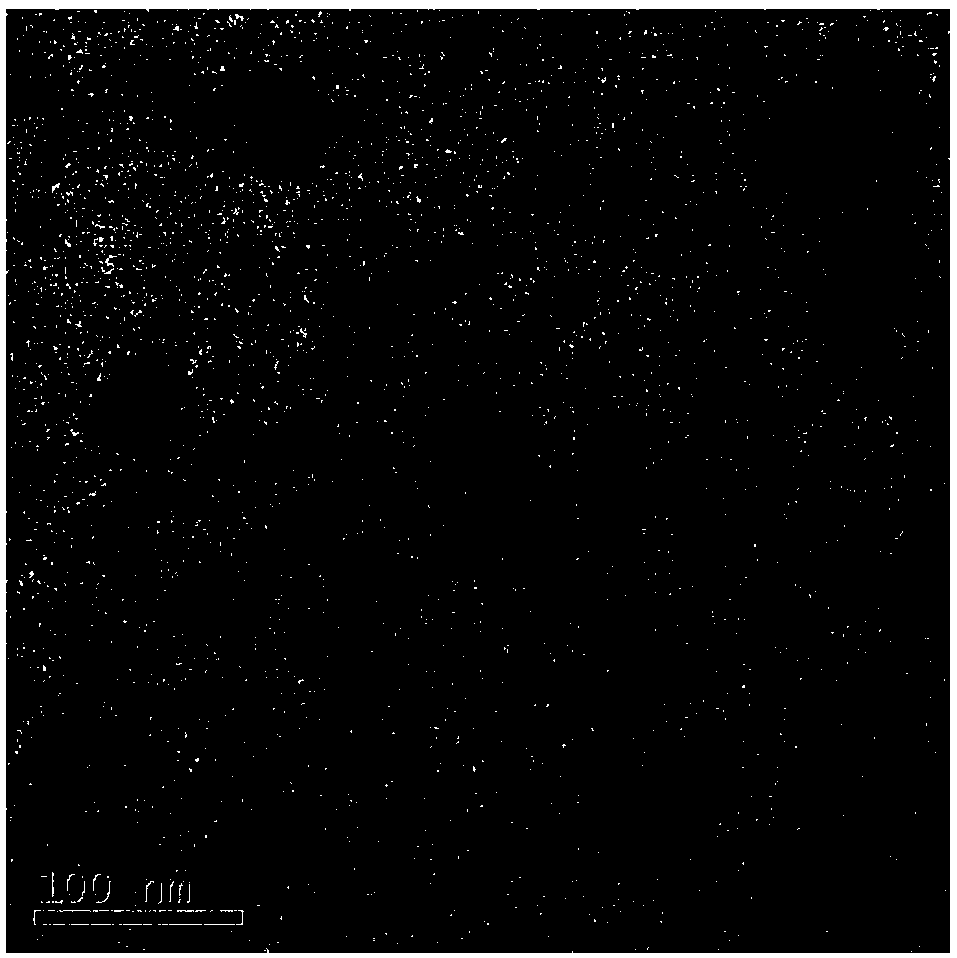

[0034]Prepare an aqueous solution of formic acid with a mass fraction of 90%, then add copper nitrate to the formic acid solution, stir for 5 minutes in the dark to dissolve, and prepare a copper nitrate formic acid solution with a mass concentration of 5%; at 15°C, immerse the natural degummed mulberry silk with a mass concentration of 0.5 % Monascus phosphate buffer solution, after 20 minutes, add the above-mentioned copper nitrate formic acid solution, keep it in the dark for 1 hour, at a temperature of 4°C; add sodium borohydride to the solution soaked in silk, and stir for 0.5 hours in the dark; The obtained silk is fully washed with water, and after natural drying, the antibacterial mulberry silk fiber product is obtained; after testing, the nano-copper content in the fiber is about 9.5wt%; the X-ray diffraction test is carried out, and the X-ray diffraction angle 2θ is 43.53°, 50.24°, 74.91° °, 89.88°, these characteristic diffraction angles are consistent with the peak ...

Embodiment 2

[0037] Prepare an aqueous solution of formic acid with a mass fraction of 98%, then add copper sulfate pentahydrate to the formic acid solution, stir for 15 minutes in the dark to dissolve, and prepare a copper sulfate formic acid solution with a mass concentration of 10%; at 10°C, immerse the natural degummed mulberry silk fiber in In the Monascus phosphate buffer solution with a concentration of 0.8%, add the above-mentioned copper sulfate formic acid solution after 30 minutes, and keep it in the dark for 5 hours at a temperature of 2°C; add sodium borohydride to the solution soaked in silk, and stir in the dark for 0.5 h; The obtained degummed mulberry silk is fully washed with water, and after natural drying, the antibacterial degummed mulberry silk is obtained; after testing, the nanometer copper content in the fiber is about 15wt%; mechanical property tests show that the tensile strength reaches more than 95% of that before treatment.

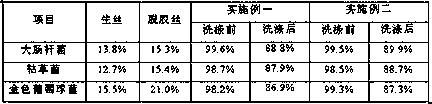

[0038] The antibacterial test adopt...

Embodiment 3

[0043] Prepare a trifluoroacetic acid ethanol solution with a mass fraction of 80%, then add copper fluoride to the solution, stir for 30 minutes in the dark to dissolve, and prepare a copper fluoride trifluoroacetic acid solution with a mass concentration of 10%; at 15°C, degummed natural tussah Immerse the silk in the Monascus phosphate buffer solution with a mass concentration of 0.6%, and then add the above-mentioned copper fluoride trifluoroacetic acid solution after 20 minutes, and keep it in the dark for 2 hours at a temperature of 1°C; add citric acid to the solution soaked in silk sodium, avoid light and stir for 1 hour; fully wash the obtained degummed natural tussah silk, and dry naturally to obtain antibacterial tussah silk fiber. After testing, the nano-copper content in the fiber is about 12wt%. X-ray diffraction test shows that a large amount of nano-copper exists inside the silk, and the X-ray diffraction test pattern shows the Nano-copper characteristic diffra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com