Antibacterial and antistatic polyester resin slice

A polyester resin, antistatic technology, applied in the manufacture of conductive/antistatic filaments, single-component polyester rayon, chemical characteristics of fibers, etc., can solve problems such as adverse human health, accumulation of static electricity, etc.

Active Publication Date: 2013-10-16

CHANGSHU HULIAN PRINTING & DYEING

View PDF5 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the fiber filaments spun from the PET polyester chips will inevitably accumulate static electricity during use, which is not conducive to human health.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-3

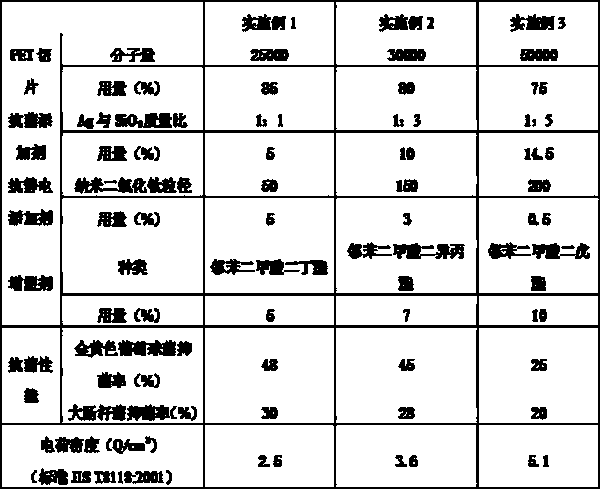

[0014] The antibacterial and antistatic polyester resin slice raw material formula of embodiment 1-3, antibacterial performance, antistatic performance are shown in Table 1:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an antibacterial and antistatic polyester resin slice which comprises the following raw materials in parts by weight: 75-85 parts of a PET (polyethylene glycol terephthalate) slice, 5-15 parts of an antibacterial additive, 0.5-5 parts of an antistatic additive and 5-10 parts of a plasticizer, wherein the molecular weight of the PET slice is 25,000-50,000 and the plasticizer is one of dibutyl-o-phthalate, diisopropyl-o-phthalate and diamyl-o-phthalate. Due to the application of the technical scheme, the antibacterial antistatic polyester resin slice has the following advantages: the antibacterial additive and the antistatic additive in the raw materials of the polyester resin slice are added at the same time, so that the polyester resin slice has antibacterial and antistatic performances at the same times; a textile prepared by the polyester resin slice is endowed with permanent antibacterial and antistatic performances; and the increasing requirement of people on the textile can be met.

Description

technical field [0001] The invention belongs to the field of spinning raw materials, and in particular relates to an antibacterial and antistatic polyester resin chip. Background technique [0002] With the continuous improvement of living standards, people's requirements for textile products are also constantly improving. Textiles with special properties such as anti-ultraviolet, antibacterial, odor absorption, antistatic, and infrared warmth are attracting more and more people's attention. [0003] In order to make textiles have the above properties, engineers have designed two methods: one is to add various nanomaterials to polyester melt, and then spin to form fibers, and then weave the fibers into cloth; The fabric is immersed in the solution containing the nanoparticle precursor, and the nanoparticle is attached to the fabric by adjusting the pH value and temperature of the solution. Among them, the textiles prepared by the latter method will lose their special proper...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L67/02C08K5/12C08K9/12C08K3/22D01F6/92D01F1/09D01F1/10

Inventor 邵峰

Owner CHANGSHU HULIAN PRINTING & DYEING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com