A three-component supersoft antibacterial yarn of fine denier polyester, antibacterial polyester and cotton and its manufacturing method

A technology of fine denier polyester and a manufacturing method, applied in textiles, papermaking, yarn and other directions, can solve the problems of poor wearing comfort, large twist of antibacterial yarn, poor softness, etc., and achieve good antibacterial performance, obvious antibacterial effect, and evenness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

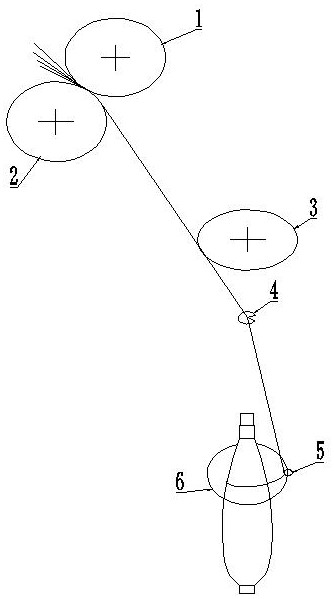

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0024] The invention provides a three-component supersoft antibacterial yarn of fine denier polyester, antibacterial polyester and cotton, which comprises fine denier polyester fiber accounting for 30%, antibacterial polyester fiber accounting for 20%, and cotton fiber accounting for 50%. Make 14.8tex (40S) blended yarn by blending process.

[0025] Its manufacture method comprises the following steps:

[0026] S1. Raw material selection: the model of fine denier polyester fiber is 0.89dtex×38mm, and the model of antibacterial polyester fiber is 1.56dtex×38mm;

[0027] S2. Raw material pretreatment: discharge the antibacterial polyester fiber and fine denier polyester fiber evenly in the disc according to the bag weight, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com