Self-aromatic natural antibacterial deodorization non-woven cloth and application thereof

A natural antibacterial, non-woven fabric technology, applied in the field of textile and weaving, can solve problems such as affecting the application of silver ion antibacterial agents, silver ions turning black, poor discoloration resistance, etc., to ensure washing resistance and antibacterial and deodorizing effects, Uniform fragrance release and long fragrance lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this embodiment, the preparation of the self-aromatic fiber includes the preparation of an aromatic sustained-release body, the preparation of a self-aromatic masterbatch, and the preparation of the self-aromatic fiber. The specific preparation process and steps are as follows:

[0049] 1) Preparation of aromatic sustained-release body: In this process, the aromatic sustained-release body adopts spray drying microcapsule technology, the polymer of the capsule wall adopts gum arabic, and the fragrance type of the aromatic essential oil in the capsule core chooses jasmine essential oil, which is calculated according to the mass percentage. , Arabic gum: Jasmine essential oil is 40%:60%, the emulsifier is Span-80, and its mass accounts for 1% of the jasmine essential oil. The preparation process includes the following steps:

[0050] Step 1: Weigh 40 parts of gum arabic in deionized water to form a solution with a concentration of 15% to form a water phase, and place the wate...

Embodiment 2

[0065] In this embodiment, the specific preparation process and steps of the natural antibacterial and deodorizing fiber are as follows:

[0066] 1) Preparation of natural antibacterial and deodorant composition: In this process, the components are calculated in parts by weight, and the proportions are as follows: 8 parts of chitosan, 15 parts of aloe oil, 8 parts of chitin, and catechins 10 parts, 40 parts of tea polyphenols, 25 parts of tea seed oil, 2 parts of tea saponin, 15 parts of grape seed extract, 25 parts of citric acid, 25 parts of amino acid chelate, 3 parts of amino acid derivative, of which, amino acid chelate The compound is composed of zinc glycinate, zinc threonine, zinc lysine and zinc methionine in a ratio of 1:1:1:1 by mass. The amino acid derivatives are composed of lysine lauryl ester and glutamic acid fiber. The plain ester and aspartate cellulose ester are configured according to the mass ratio of 0.1:0.45:0.45. The specific preparation process includes ...

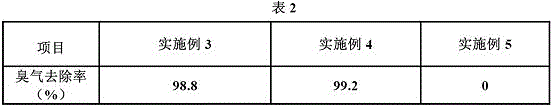

Embodiment 3

[0083] The self-aromatic natural antibacterial and deodorizing nonwoven fabric of this embodiment includes two-component fibers, self-aromatic fibers, and natural antibacterial and deodorizing fibers. The self-aromatic fibers are prepared in Example 1, and the natural antibacterial and deodorizing fibers are prepared in Example 2. The bi-component fiber is made of 20 parts of polyethylene and 100 parts of polypropylene, melted and extruded into the composite spinning box through a twin-screw extruder. The spinning process is the same as that in Example 1 or Example 2. Ethylene and polypropylene pass through the skin layer spinneret holes and the core layer spinneret holes of the skin-core composite spinneret respectively, and then compound into the composite holes of the composite plate to form two-component fibers. The preparation steps of the self-aromatic natural antibacterial and deodorizing nonwoven fabric of this embodiment are as follows:

[0084] Step 1: Accurately weigh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com