Preparation method for polyolefin film with anti-bacterial function

A polyolefin and film technology, applied in the field of polyolefin film and its preparation, can solve the problems of antibacterial coating and film fastness, inability to achieve bactericidal effect, large amount of bactericide added, etc., to achieve balanced mechanical properties, control Effects of thickness and variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of preparation method of polyolefin film with antibacterial function, the preparation method of described polyolefin film with antibacterial function comprises the following steps:

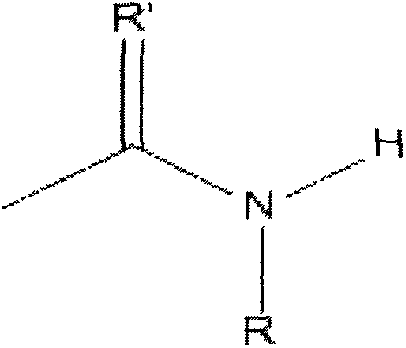

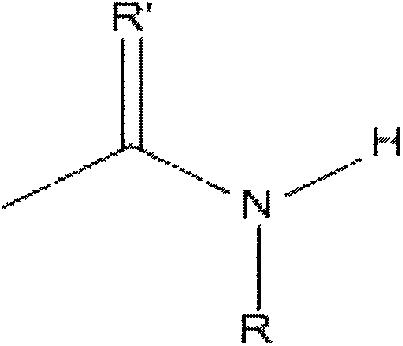

[0043] A Preparation of polyolefin masterbatch containing amine structural functional monomer

[0044] Mix the polyolefin material, the functional monomer containing double bonds and amine structure, and the initiator according to the following mass ratio, wherein,

[0045] Polyolefin 100

[0046] Functional monomer with double bond and amine structure 1~10

[0047] Initiator 0.1~4

[0048]Add it into the hopper of a twin-screw extruder, extrude through melt reaction, and pelletize into antibacterial polyamide chips. Among them, the temperature settings of each heating zone of the screw are: Zone 1: 230°C; Zone 2: 240°C; Zone 3: 250°C; Zone 4: 245°C; Zone 5: 245°C; Zone 6: 250; Zone 7: 250°C ; Head: 260 ° C; residence time 2 ~ 3min. The pressure is 15MPa.

[0049] That is, the ...

Embodiment 1

[0072] 1000 kg of polyethylene (PE), 10 kg of AAM, and 1 kg of DCP were dried for 2 hours, then mixed evenly, and nitrogen was introduced into the container of the screw extruder for 5 minutes to remove oxygen. The mixed material is put into the hopper of the twin-screw extruder, extruded through melting reaction, and granulated into antibacterial particles. Among them, the temperature settings of each heating zone of the twin-screw extruder are: zone 1 temperature: 130°C; zone 2: 150°C; zone 3: 160°C; zone 4: 165°C; zone 5: 170°C; zone 6: 170°C ; Zone 7: 165°C; Machine head: 175°C; residence time: 2-3 minutes. The pressure is 15MPa.

[0073] Add the above-prepared polyolefin antibacterial masterbatch into a film blowing machine at a processing temperature of 150° C. to prepare a film with an amine structure having a covalent bond on the surface.

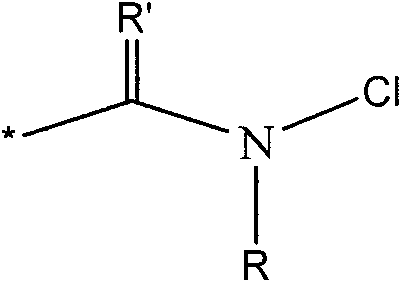

[0074] Soak the above film in a mixed solution of TX-100 with a concentration of 1500 ppm active chlorine and 0.05% mass fractio...

Embodiment 2

[0076] 1000 kg of polypropylene (PP), 10 kg of MAM, and 1 kg of DCP were dried for 2 hours, then mixed uniformly, and nitrogen was introduced into the container of the screw extruder for 5 minutes to remove oxygen. The mixed material is put into the hopper of the twin-screw extruder, extruded through melting reaction, and granulated into antibacterial particles. Among them, the temperature settings of each heating zone of the twin-screw extruder are as follows: zone 1 temperature: 150°C; zone 2: 160°C; zone 3: 170°C; zone 4: 175°C; zone 5: 180°C; zone 6: 175°C ; Zone 7: 170°C; Machine head: 185°C; residence time: 2-3 minutes. The pressure is 15MPa.

[0077] The polyolefin antibacterial masterbatch prepared above is added into a film blowing machine to prepare a film with an amine structure having a covalent bond on the surface.

[0078] Soak the above film in a mixed solution of TX-100 with a concentration of 1500 ppm active chlorine and 0.05% mass fraction for 30 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com