Easy-to-clean knitted fabric

A knitted fabric and easy decontamination technology, applied in the field of knitted fabrics, can solve the problems of simple function and poor washability, and achieve the effects of improving durability and reducing stains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

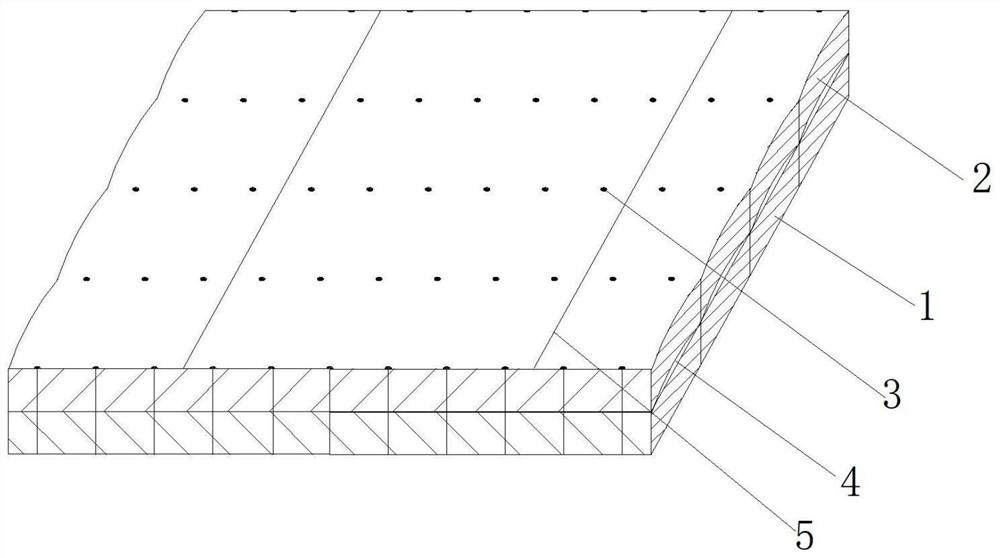

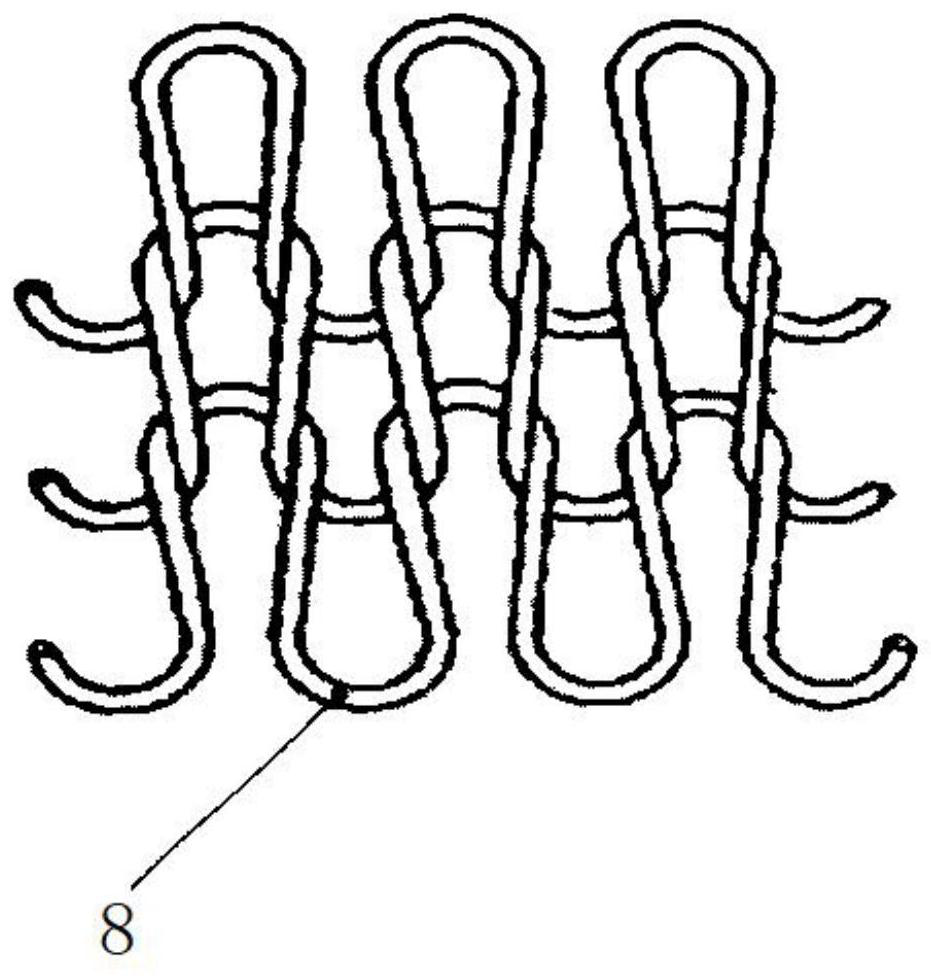

[0028] An easy-to-decontaminate knitted fabric is composed of a weft-knitted double-sided knitted fabric in which a front fabric 1 and a back fabric 2 are connected at connection points 3 .

[0029] The main points of its production process are as follows:

[0030] Raw yarn processing - yarn processing - knitting and weaving - fabric dyeing and finishing

[0031] In raw yarn processing stage:

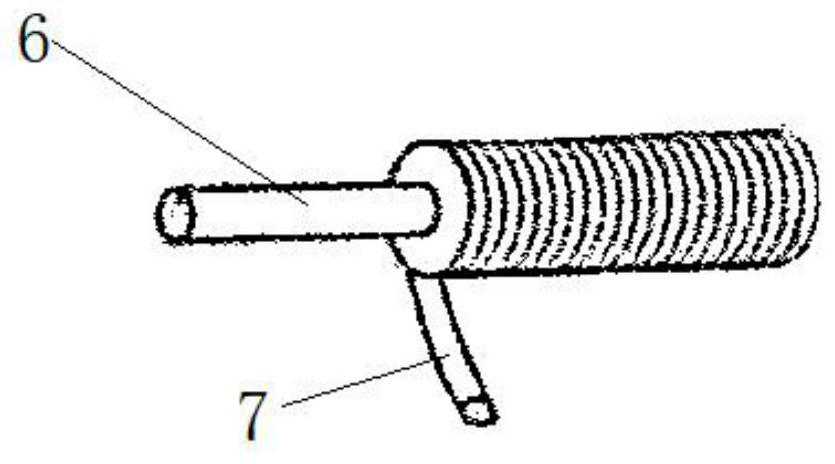

[0032] The polypropylene filament used as the core yarn 6 of the covered yarn is finished with a water-proof and oil-proof auxiliary agent.

[0033] Using HUNTSMAN's NB-NH waterproof and oil-proof finishing agent is used to treat polypropylene cheese.

[0034] The yarn treatment process is as follows:

[0035] Yarn preparation:

[0036] 1) Yarn winding density is controlled at 0.32-0.35g / cm 3 ,

[0037] 2) The weight of each bobbin should not exceed 850 grams.

[0038] Yarn pretreatment:

[0039] 1) Please choose a large bath ratio for the dyeing vat, generally controlled at 1...

Embodiment 2

[0068] An easy-to-decontaminate knitted fabric is composed of a weft-knitted double-sided knitted fabric in which a front fabric 1 and a back fabric 2 are connected at connection points 3 .

[0069] The main points of its production process are as follows:

[0070] Core yarn treatment - processing covered yarn - knitting and weaving - fabric dyeing and finishing

[0071] In raw yarn processing stage:

[0072] The polypropylene filament used as the covered yarn core yarn 6 is finished with a waterproof and oil-proof auxiliary agent.

[0073] Using HUNTSMAN's NB-NH waterproof and oil-proof finishing agent is used to treat polypropylene cheese.

[0074] The yarn treatment process is as follows:

[0075] Yarn preparation:

[0076] 1) Yarn winding density is controlled at 0.30-0.33g / cm 3 ,

[0077] 2) The weight of each bobbin should not exceed 900 grams.

[0078] Yarn pretreatment:

[0079] 1) The liquor ratio of the dyeing vat should be controlled at 1:7-8.

[0080] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com