Plasma ignition and combustion stabilization device for IGBT (insulated gate bipolar transistor) rectification power supply

A plasma ignition and stable combustion device technology, which is applied in the direction of burners, burners, and combustion methods for burning powder fuels, can solve the problems of unsuccessful ignition and unstable combustion, and achieve improved power factor, stable operation, and safe work The effect of zone width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

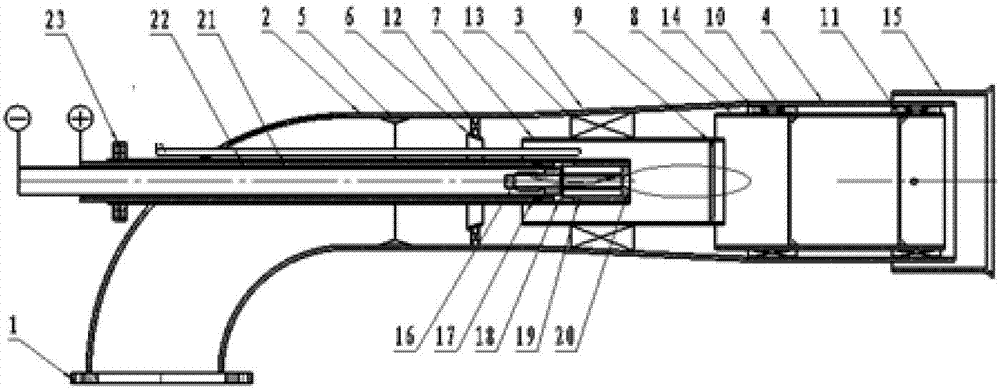

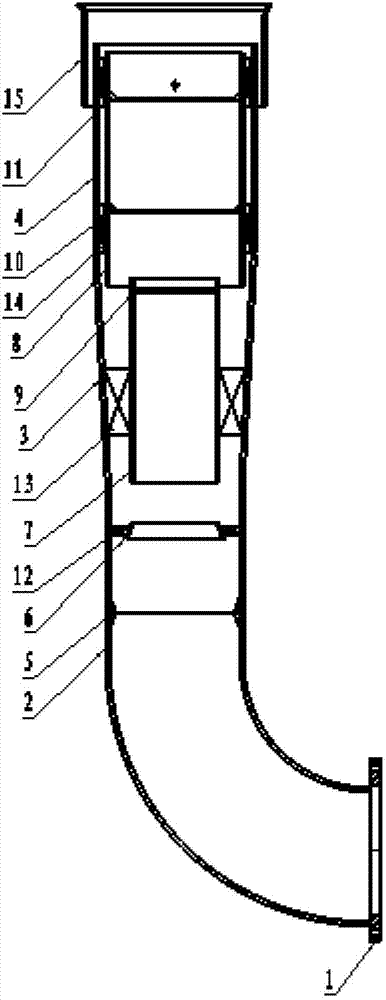

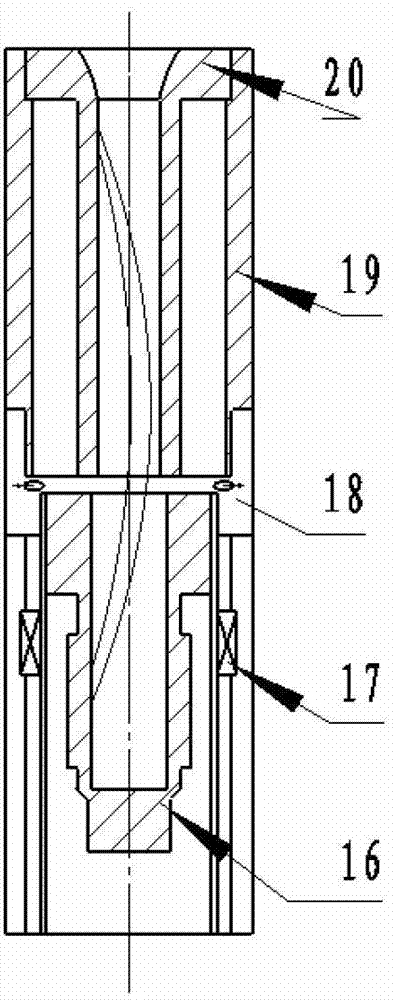

[0032] like figure 1 , 2 , 3, a kind of IGBT (insulated gate bipolar) transistor rectification power supply plasma ignition and stable combustion device of the present invention includes a collision type coal powder concentration staged combustion coal powder burner and a parallel flow arc plasma spray gun, wherein the collision type The pulverized coal concentration staged combustion pulverized coal burner includes primary air powder inlet 1, straight pipe section 2, conical pipe section 3, outer nozzle 4, collision concentration block 5, collision concentration ring 6, inner combustion chamber 7, outer combustion chamber 8, The disturbance block 9 of the inner combustion chamber, the rear disturbance block 10 of the outer combustion chamber, the front disturbance block 11 of the outer combustion chamber, the collision concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com