Natural antibacterial and deodorizing finishing agent for non-woven fabrics and preparation method of finishing agent

A natural antibacterial, non-woven fabric technology, applied in textiles and papermaking, fiber treatment, biochemical treatment of velvet protectant/mothproof agent, etc., can solve the problem of silver ion antibacterial agent application, silver ion turning black, anti-discoloration Poor ability and other problems, to achieve the effect of ensuring washing resistance, antibacterial and deodorizing effects, long-lasting fragrance, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In the present embodiment, the preparation process and steps of the natural antibacterial and deodorant finishing agent for nonwovens are as follows:

[0041] (1) Preparatory work:

[0042] Ingredients of natural antibacterial deodorant composition: chitosan 2kg; aloe vera oil 6 kg; chitin 2.5 kg; catechin 3 kg; tea polyphenol 9 kg; tea seed oil 5 kg; tea saponin 0.4 kg; grape seed Extract 4.5 kg; citric acid 6 kg; amino acid chelate 6 kg; amino acid derivatives 2.5 kg; emulsifier 2 kg, deionized water 100 kg.

[0043] Ingredients of natural antibacterial deodorant finishing agent: polyoxyethylene sorbitan tristearate 10 kg; macrogol glyceryl ether 6 kg; ester quaternary ammonium salt 5 kg; natural antibacterial composition 10 kg; fragrance slow release Body 6 kg; deionized water 63 kg.

[0044] (2) Preparation process:

[0045] Step 1: Preparation of natural antibacterial and deodorant composition: first dissolve citric acid in deionized water and stir to obtain sol...

Embodiment 2

[0051] In the present embodiment, the preparation process and steps of the natural antibacterial and deodorant finishing agent for nonwovens are as follows:

[0052] (1) Preparatory work:

[0053] Ingredients of natural antibacterial deodorant composition: chitosan 2kg; aloe vera oil 6 kg; chitin 2.5 kg; catechin 3 kg; tea polyphenol 9 kg; tea seed oil 5 kg; tea saponin 0.4 kg; grape seed Extract 4.5 kg; citric acid 6 kg; amino acid chelate 6 kg; amino acid derivatives 2.5 kg; emulsifier 2 kg, deionized water 100 kg.

[0054] Ingredients of natural antibacterial deodorant finishing agent: polyoxyethylene sorbitan tristearate 15kg; macrogol glyceryl ether 8 kg; ester quaternary ammonium salt 7 kg; natural antibacterial deodorant composition 15kg; fragrance sustained release 4 kg body, 51 kg deionized water.

[0055] (2) Preparation process: According to the steps of Example 1, a natural antibacterial and deodorant finishing agent was prepared.

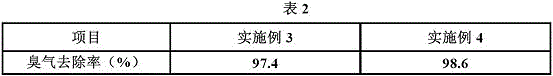

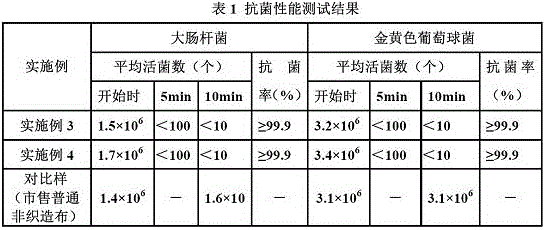

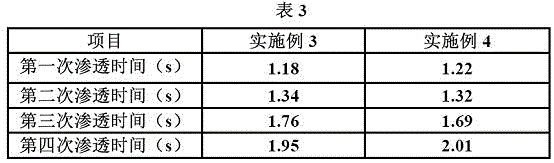

Embodiment 3

[0057] In this embodiment, the finishing agent of Example 1 is used to finish the polypropylene spunbonded nonwoven fabric, and the square gram weight of the polypropylene spunbonded nonwoven fabric is 18g / m 2 , the finishing steps are as follows:

[0058] Step 1: Dilute the natural antibacterial and deodorant finishing agent prepared in Example 1 to prepare a solution with a concentration of 20% to obtain a finishing solution.

[0059] Step 2: Place the nonwoven fabric in the finishing solution and soak it for 20-30 minutes at room temperature.

[0060] Step 3: The nonwoven fabric obtained in step (2) is dried by rolling by adjusting and controlling the distance between the rolls.

[0061] Step 4: Set the drying temperature to 110° C., and dry and solidify the nonwoven fabric obtained in step (3).

[0062] A kind of polypropylene spun-bonded non-woven fabric comprising natural antibacterial and deodorant finishing agent has been obtained through the above steps, and the wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com