Anchoring method applicable to large-tonnage FRP inhaul cable

An anchoring method and large-tonnage technology, applied in the direction of sheet pile walls, structural elements, building components, etc., can solve problems such as stress concentration, and achieve the effects of regular cross-sectional shape, good bonding performance, and simple and convenient molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

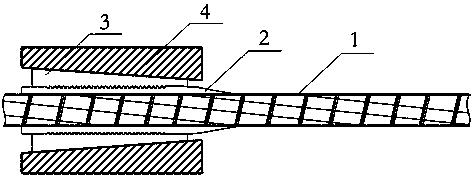

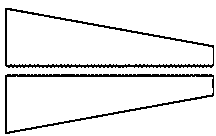

[0034] Example 1: See figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown. figure 1 It is a structural schematic diagram of the FRP cable anchor of the present invention, figure 2 It is a schematic diagram of the winding fiber anchoring of Embodiment 1 of the present invention, image 3 It is a schematic diagram of the structure of the steel clip in Embodiment 1 of the present invention, Figure 4 It is a structural schematic diagram of the steel anchor cup of Embodiment 1 of the present invention, Figure 5It is a schematic diagram of the notch effect of the FRP tendon / cable anchorage system. The load transmission medium 300 used in this embodiment is a steel clip 3 , including an FRP cable 1 , a molded protective layer 2 , a tapered steel clip 3 and a steel sleeve 4 . First wind the fiber roving 6 of the pre-impregnated resin 5 on the surface of the FRP cable, select different winding layers according to the diameter of the anchoring FRP cable, and mold ...

Embodiment 2

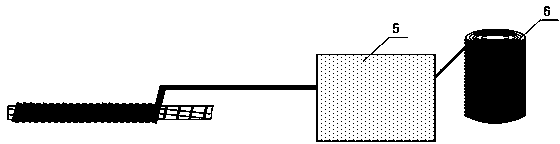

[0035] Example 2: See Figure 6 shown. Its basic structure is the same as that of Embodiment 1, except that the load transmission medium 3 is an expansion material 5 . First, the fiber roving pre-impregnated on the surface of the FRP cable is wound, and the number of winding layers is selected according to the diameter of the anchoring FRP cable. After molding, the FRP cable 1 and the protective layer 2 are molded into a whole. The interface between the cable 1 and the protective transition layer 2 has extremely high shear strength, forming a stressed buffer layer to indirectly protect the FRP cable. Then pour the expansion material 5 between the steel anchor cup 4 and the molded FRP cable 1 with a protective transition layer 2, and rely on the positive interface pressure generated by the expansion material 5 after solidification and expansion to provide the anchoring force, that is, an FRP cable anchoring system is formed .

Embodiment 3

[0036] Example 3: See Figure 7 shown. Its basic structure is the same as that of Embodiment 1, except that the load transmission medium 3 is a material 6 with radial stiffness variation. Figure 8 , Figure 9 , Figure 10 The distribution curves of radial compressive stress and shear stress on the surface of FRP cables, the solid line is the load transfer material A without mechanical performance design, and the dotted line is the load transfer material B designed according to the stress distribution in the anchorage area, after the mechanical performance design The anchorage system can effectively reduce the stress peak at the beginning of loading in the anchorage area, which is beneficial to the stress of anisotropic FRP cables in the anchorage area, and can anchor multiple FRP cables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com