Chemical industry heating stove using water coal slurry as fuel

A technology of chemical industry and coal-water slurry, which is applied in the combustion of block fuel and liquid fuel, the combustion of block fuel and gaseous fuel, and the combustion of block fuel and powder fuel, which can solve the difficulty of manufacturing and installation Large, air pollution, high sulfur content and other problems, to achieve the effect of reducing equipment investment, uniform heat transfer, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

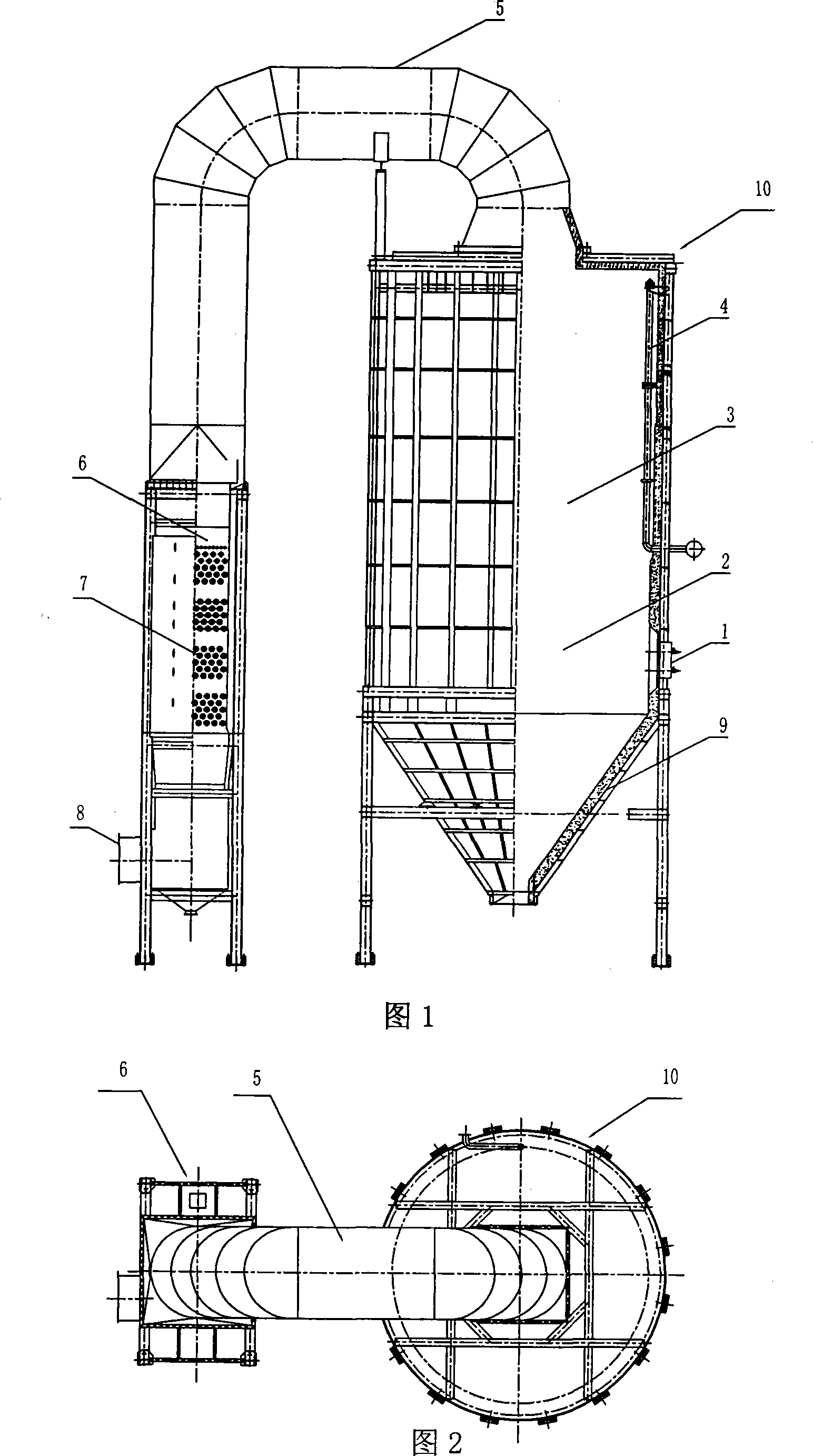

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] As shown in Figure 1 and 2.

[0025] A chemical industrial heating furnace using coal water slurry as fuel, comprising a furnace body 10, the lower part of the furnace body 10 is connected with an ash hopper 9, and the furnace body 10 is provided with a combustion chamber 2 and a radiation section 3, and the combustion chamber 2 is located below , the radiant section 3 is on the top, and four or more (such as 6, 8, 10, etc., etc., the specific number should depend on the inner diameter of the furnace body 10) are arranged in a tangential circle on the body of furnace 10 around the combustion chamber 2. The coal-water slurry burner nozzle 1 that sprays the coal-water slurry into the combustion chamber is calculated and determined by calculating the temperature required for combustion. In the radiant section 3, there are vertical heat pipes 4 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com