Formwork for limiting a diaphragm wall section, formwork element and method for manufacturing a diaphragm wall in the ground

A formwork and part technology, applied in the field of formwork elements, formwork parts and ground that limit the section of the ditch wall, can solve the problems of long storage time, heavy parts, etc., and achieve the effect of short production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

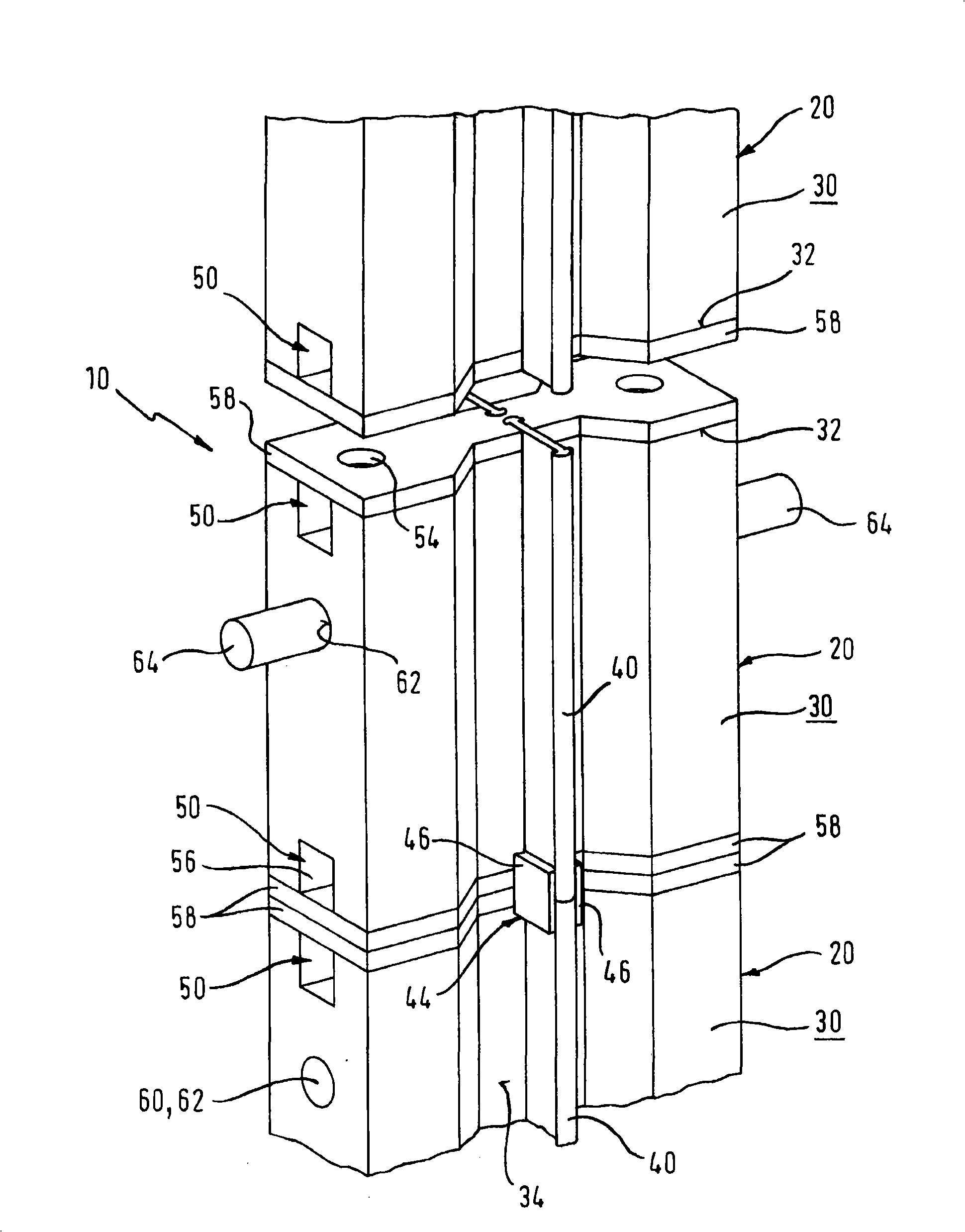

[0035] In the assembled state, figure 1 The illustrated template element 10 includes a plurality of template parts 20, one of which is in figure 1 It is displayed completely in the middle, and the part of the template adjacent to the upper and lower parts is displayed. The length of the template part 20 is approximately 6 m.

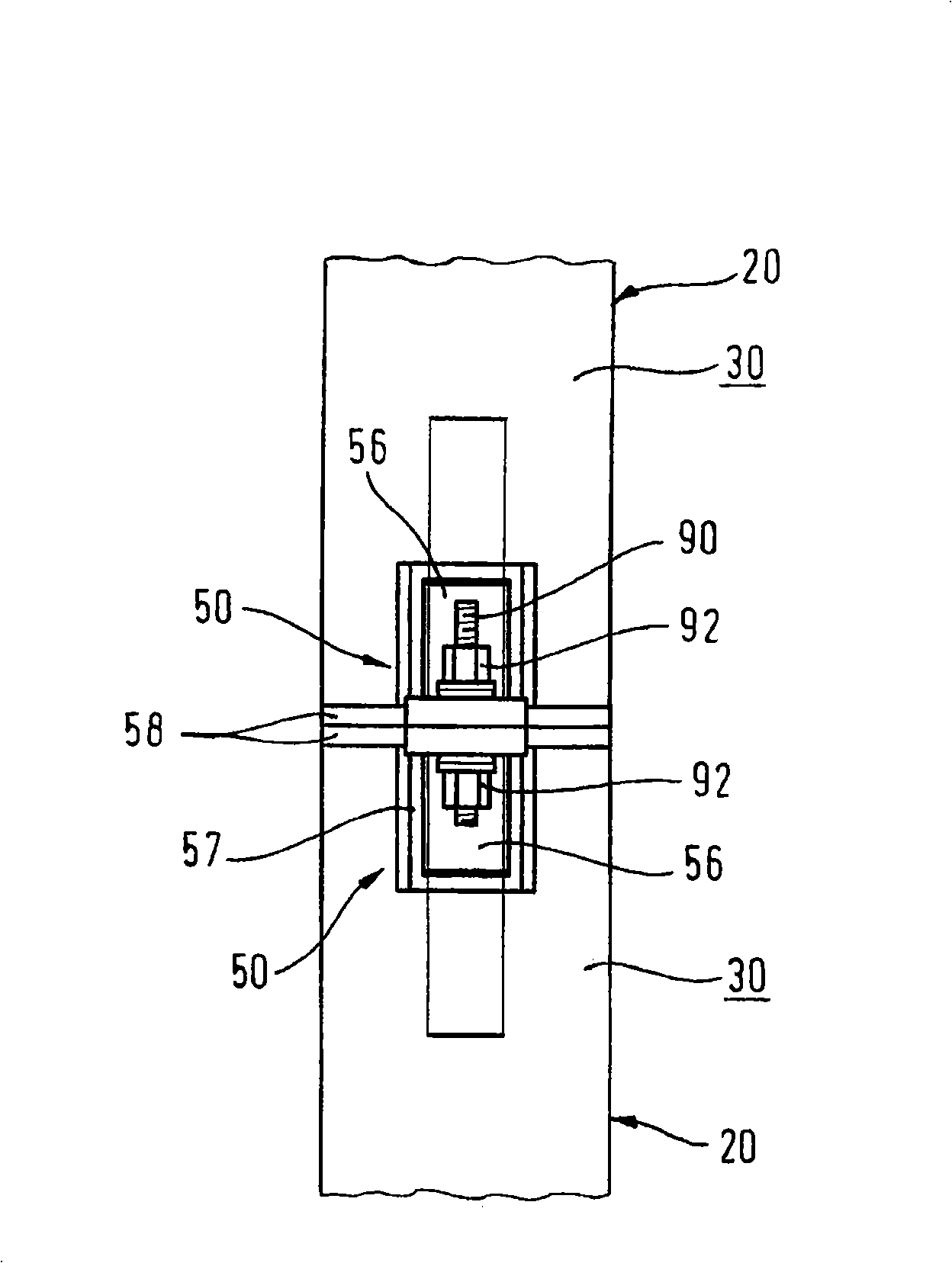

[0036] The template parts 20 each include a base 30 having a substantially wall-like or plate-like shape. According to the present invention, a connecting device 50 is provided at the horizontal front surface 32 of the base body 30 of the template part 20, and the connecting device 50 is used for the subsequent connection of the template part 20, respectively. In the example shown, the connecting device 50 is a threaded connection (not shown in detail) and is arranged in the recess 56 of the concrete base 30. The threaded connections respectively pass through the openings 54 to reach the adjacent template parts 20. The notch 56 is limited by the metal plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com