Pit patching material for converter

A technology for repairing furnace materials and converters, which is applied in the field of refractory materials and can solve problems such as material turning, splashing, and affecting the normal production of converters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

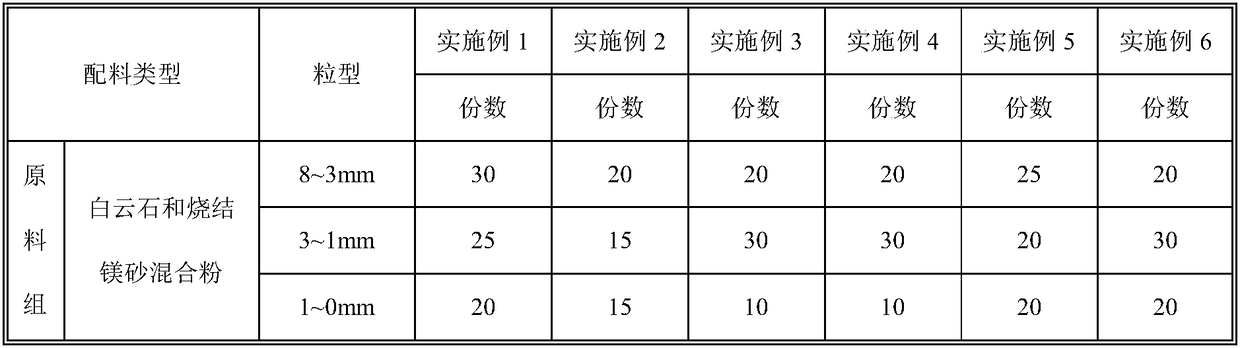

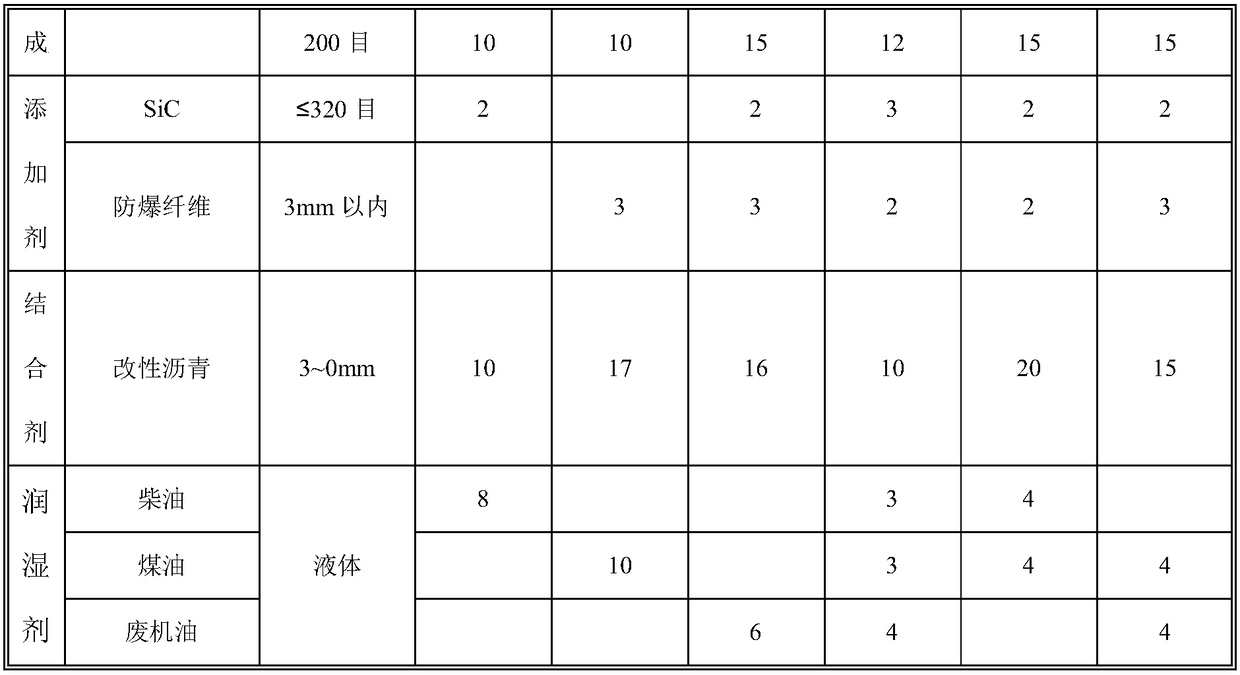

Examples

Embodiment

[0020]

[0021]

[0022] The invention can improve the hydration resistance and erosion resistance of the product by using the composite magnesium dolomite material. The use of modified asphalt binders can overcome many shortcomings of using a single medium temperature asphalt binder, and comprehensively improve the quality of the binder. The present invention proposes a new way to make up the furnace material for the converter, which is of great significance for energy saving, consumption reduction, environmental protection, and economic benefit increase. After being used in a steel plant, the average life span reaches 30 heats. The present invention proposes a new way for refilling materials for converters, which is of great significance for energy saving, consumption reduction, environmental protection, and economic benefit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com