Water-based epoxy floor paint composition capable of being used outdoors, and preparation method thereof

An epoxy floor paint, water-based epoxy resin technology, applied in epoxy resin coatings, coatings and other directions, can solve the problems of short surface dry/hard dry time, reduce the hardness of the paint film, short hardening time, etc., to achieve good resistance. Effects of UV properties, short tack-free time, short hardening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation steps of A component in the present embodiment 1 are as follows:

[0048] (1) Preparation of water-based epoxy resin: first, turn on the disperser at low speed, put emulsifier and liquid epoxy resin E-51 into the disperser, set the stirring speed to 1000-2000rpm after putting in, under high-speed shear condition First mix the emulsifier and liquid epoxy resin for 10-50 minutes until uniform, then slowly add deionized water to the system under the shear condition of 500-2500rpm until the epoxy equivalent of the prepared water-based epoxy resin is 400 Stop adding water when the water content gradually increases, and the whole system gradually changes from water-in-oil to oil-in-water, and finally forms a uniform and stable water-based epoxy emulsion system.

[0049] (2) Preparation of acrylic-based resin hybrid modified water-based epoxy resin: start the disperser at low speed, first put pure acrylic emulsion BY-510TS into the disperser, set the stirring s...

Embodiment 2

[0055] The A-component acrylic-based resin hybrid modified water-based epoxy resin in this example is purchased from AEH-2014 of DOW Company, and the preparation steps of the B-component of the acrylic-modified epoxy resin are as follows:

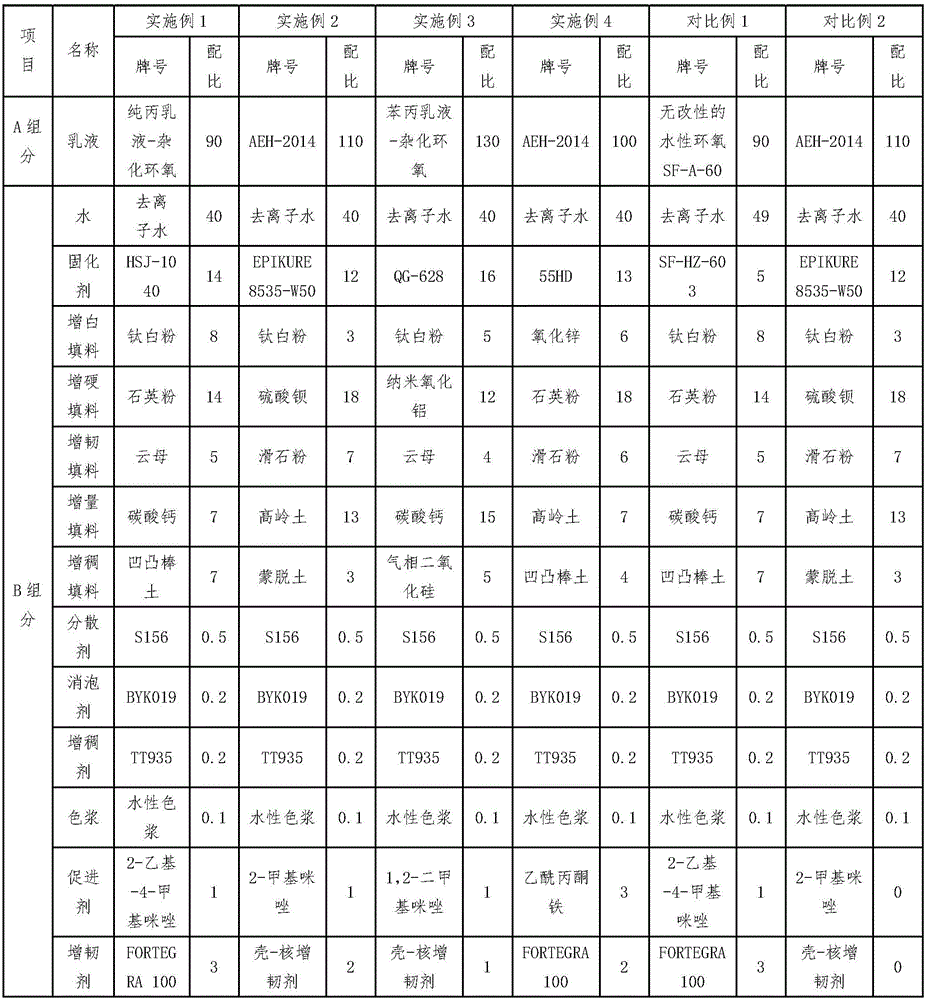

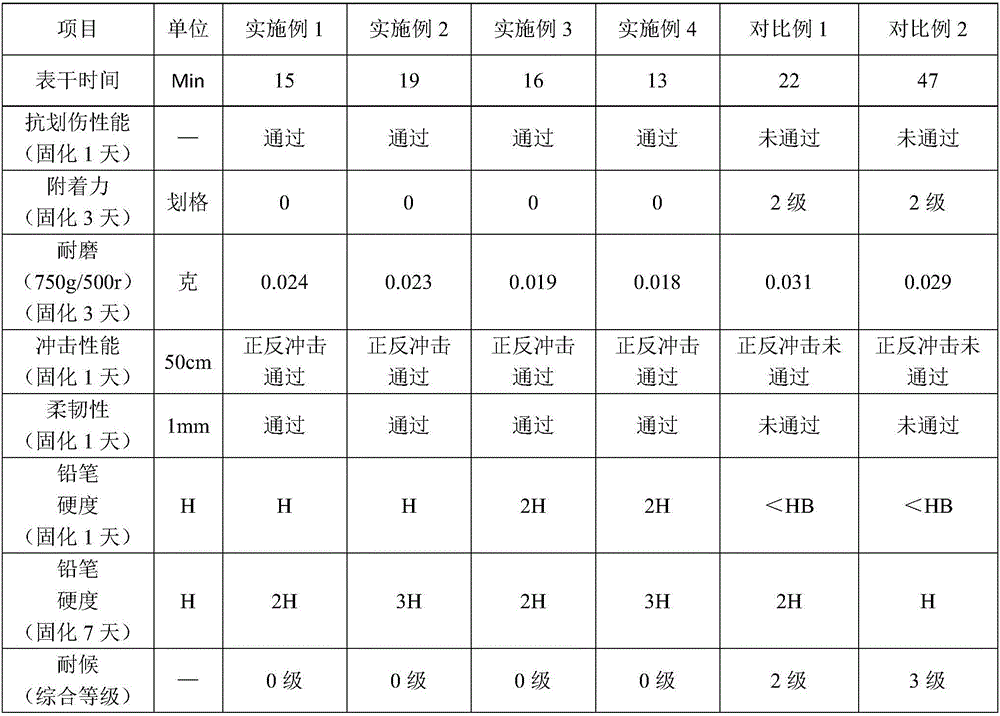

[0056] First, add 40 parts of deionized water to the stirring container, set the speed at 200-500rpm, first add dispersant and defoamer to it, then adjust the stirring speed to 700-1000rpm, stir for 3-10min; then reduce the stirring speed to 200- 500rpm, add epoxy resin curing agent and thickener respectively, adjust the stirring speed to 800-1200rpm, stir for 10-20min; then reduce the stirring speed to 200-500rpm, respectively add 4000 mesh whitening filler, 1250 mesh hardening filler, 800-mesh toughening filler, 800-mesh incremental filler, 800-mesh thickening filler accelerator, toughening agent and color paste, etc. After feeding, adjust the stirring speed to 800-1200rpm, stir for 15-20min to obtain component B, each group See Table 1 f...

Embodiment 3

[0060] The preparation steps of A component in the present embodiment 3 are as follows:

[0061] (1), the preparation of water-based epoxy resin: first open the disperser at a low speed, drop into emulsifier, liquid epoxy resin E-51 and ethylene glycol diglycidyl ether in the disperser, wherein ethylene glycol diglycidyl ether The dosage is 5% of E-51. After the input is completed, set the stirring speed to 1000-2000rpm. Under the condition of high-speed shearing, first mix the emulsifier and liquid epoxy resin for 10-50min until uniform, and then mix the emulsifier and liquid epoxy resin at 500-2500rpm Slowly add deionized water to the system under certain conditions, and stop adding water until the epoxy equivalent of the prepared water-based epoxy resin is 400. As the amount of water gradually increases, the entire system gradually changes from water-in-oil to oil-in-water , and finally form a uniform and stable water-based epoxy emulsion system.

[0062] (2) Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com