High-temperature corrosive-proof plastic material and preparation method thereof

A high-temperature wear-resistant and plastic technology, applied in the field of high-temperature-resistant materials and their preparation, can solve the problems of insufficient time, inconvenience, and long consumption time, and achieve rapid repair, convenient construction, and reduce the loss of furnace shutdown. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

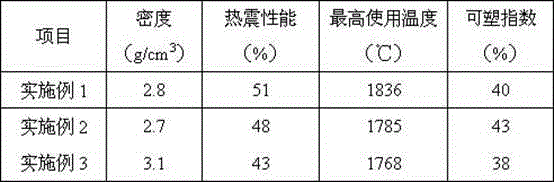

Examples

Embodiment 1

[0021] High temperature wear-resistant plastics, prepared from the following raw materials: according to parts by weight,

[0022] 10 parts of activated alumina powder with particle size of 0.001~0.015mm;

[0023] 5 parts of super high alumina powder with particle size of 0~1mm

[0024] 3 parts of super high alumina powder with a particle size of 1~3mm;

[0025] 10 parts of super high alumina powder with a particle size of 3~5mm;

[0026] 8 parts of super high alumina powder with particle size of 5~8mm;

[0027] 5 parts of silicon carbide powder with a particle size of 0.1~0.3mm;

[0028] 10 parts of silicon carbide powder with a particle size of 0.5~1mm;

[0029] Binder: 7 parts of aluminum phosphate, 20 parts of aluminum sulfate, 10 parts of calcium carbonate powder;

[0030] Additives: 10 parts of tartaric acid.

[0031] The preparation method of high temperature wear-resistant plastic includes the following steps:

[0032] (1) Dry activated alumina powder, super high-aluminum powder, sili...

Embodiment 2

[0035] High temperature wear-resistant plastics, prepared from the following raw materials: according to parts by weight,

[0036] 18 parts of activated alumina powder with a particle size of 0.001~0.015mm;

[0037] 8 parts of special high alumina powder with particle size of 0~1mm

[0038] 7 parts of super high alumina powder with a particle size of 1~3mm;

[0039] 19 parts of super high alumina powder with a particle size of 3~5mm;

[0040] 12 parts of super high alumina powder with particle size of 5~8mm;

[0041] 7 parts of silicon carbide powder with a particle size of 0.1~0.3mm;

[0042] 15 parts of silicon carbide powder with a particle size of 0.5~1mm;

[0043] Binder: 12 parts of aluminum phosphate, 15 parts of aluminum sulfate, 16 parts of calcium carbonate powder;

[0044] Additives: 14 parts of tartaric acid.

[0045] The preparation method of high temperature wear-resistant plastic includes the following steps:

[0046] (1) Dry activated alumina powder, super high-aluminum powder...

Embodiment 3

[0049] High temperature wear-resistant plastics, prepared from the following raw materials: according to parts by weight,

[0050] 26 parts of activated alumina powder with particle size of 0.001~0.015mm;

[0051] 10 parts of special high alumina powder with particle size of 0~1mm

[0052] 13 parts of super high alumina powder with a particle size of 1~3mm;

[0053] 25 parts of super high alumina powder with particle size of 3~5mm;

[0054] 16 parts of super high alumina powder with particle size of 5~8mm;

[0055] 10 parts of silicon carbide powder with a particle size of 0.1~0.3mm;

[0056] 20 parts of silicon carbide powder with a particle size of 0.5~1mm;

[0057] Binder: 16 parts of aluminum phosphate, 30 parts of aluminum sulfate, 20 parts of calcium carbonate powder;

[0058] Additive: 20 parts of tartaric acid.

[0059] The preparation method of high temperature wear-resistant plastic includes the following steps:

[0060] (1) Dry activated alumina powder, super high-aluminum powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com