Jointless construction structure combining SCC (self-compacting concrete) and common concrete

A technology of ordinary concrete and high-performance concrete, applied in underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of complicated post-casting process, achieve the effects of saving construction period, simple construction structure, and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

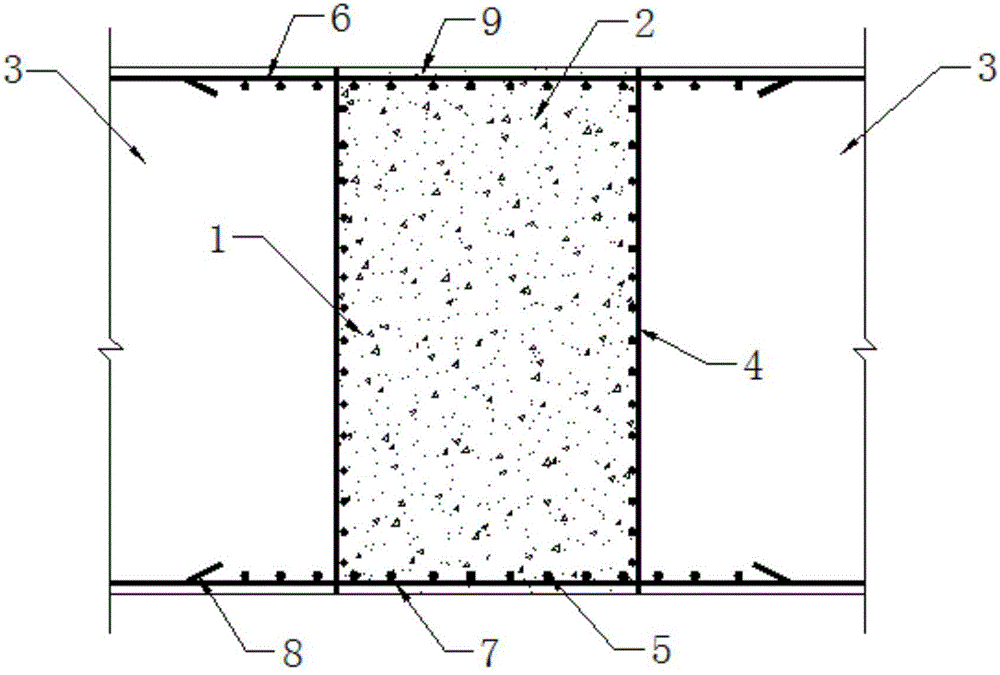

[0014] Such as figure 1 As shown, a seamless construction structure combining SCC and ordinary concrete according to the present invention includes reinforcement strip 1, SCC high-performance concrete 2, non-reinforcement strip 3, dense-hole steel wire mesh 4, horizontal temperature steel bar 5, upper steel bar 6, and lower steel bar 7. Vertical steel bar 8 and concrete protective layer 9, SCC high-performance concrete 2 is evenly arranged in the reinforcement belt 1, and non-reinforcement belt 3 is arranged at both ends of the SCC high-performance concrete 2, and the SCC high-performance concrete 2 and two Between the non-reinforcing bands 3, a dense-porous steel wire mesh 4 is arranged, and one end of the dense-porous steel mesh 4 is connected with a horizontal temperature steel bar 5, and the horizontal temperature steel bar 5 is connected with the upper steel bar 6 and the lower steel bar 7, and the upper steel bar 6 and the lower steel bar 7 are connected. Lower reinforci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com