Polymethylmethacrylate waterproof paint and preparation method thereof

A technology of polymethyl methacrylate and methyl methacrylate, which is applied in the direction of coating, etc., can solve the problems of poor weather resistance, limit the application and promotion of polyurea, and cannot be suitable for low-temperature construction, etc., and achieve a simple production and preparation process , excellent chemical resistance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

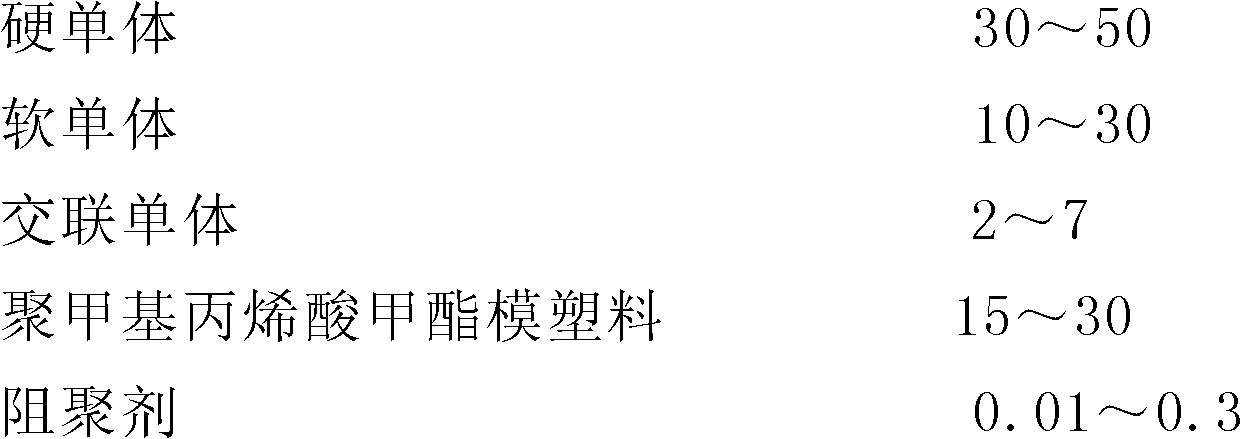

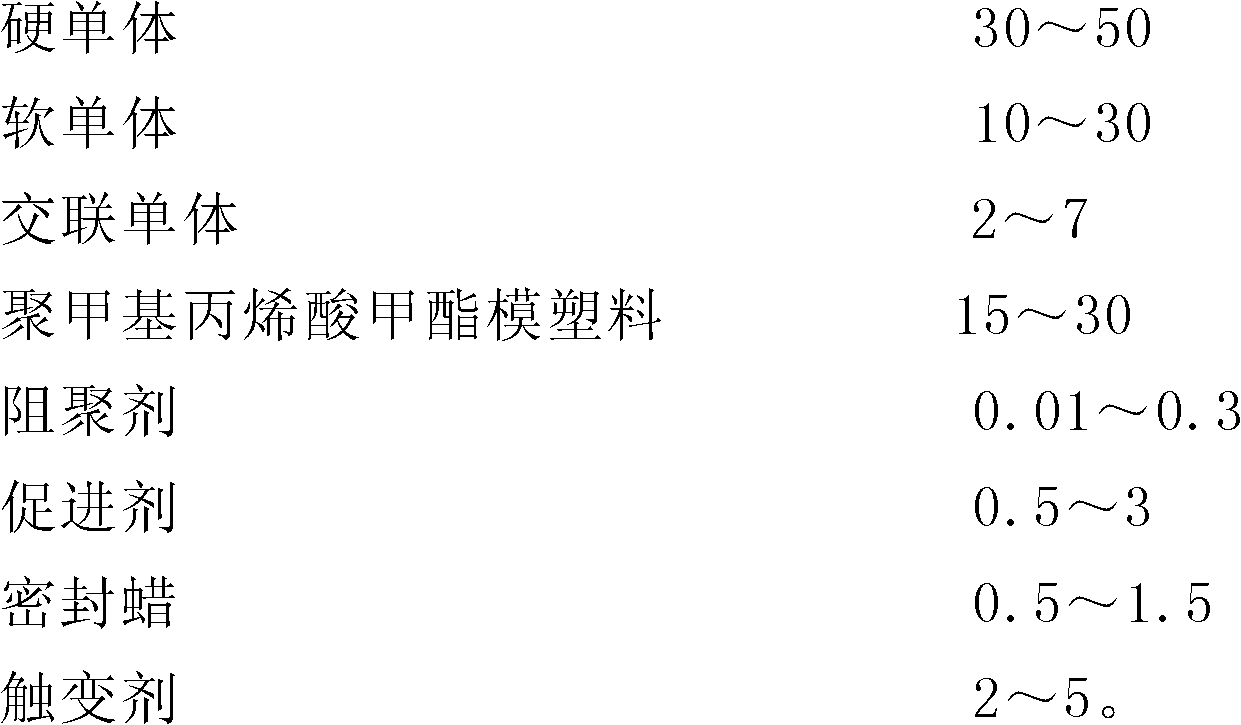

Method used

Image

Examples

Embodiment 1

[0050] Accurately weigh 40 parts of methyl methacrylate, 25 parts of pentyl acrylate, and 2 parts of polyethylene glycol dimethacrylate into the reaction kettle, and start stirring and heating. When the temperature rose to 30°C, 29.88 parts of PMMA molding compound with a mass-average molecular weight of 20,000 were added, and the temperature was controlled at 80°C and stirred for 4 hours before cooling down. When the temperature drops to 65°C, add 0.02 part of hydroquinone, 0.25 part of N,N-dimethylaniline, 0.25 part of N,N dimethyl-p-toluidine, 0.1 part of cobalt naphthenate, and 0.5 part of softening 2 parts of paraffin wax and fumed silica at a temperature of 45°C-70°C. After continuing to cool down to 45°C, filter and package to obtain component A resin liquid.

Embodiment 2

[0052] Accurately weigh 37.65 parts of methyl methacrylate, 10 parts of butyl methacrylate, 10 parts of isooctyl acrylate, 2 parts of polypropylene glycol dimethacrylate, and 5 parts of butanediol dimethacrylate in the reaction kettle , start stirring and heating. When the temperature rose to 45°C, 30 parts of PMMA molding compound with a mass-average molecular weight of 50,000 were added, and the temperature was controlled at 70°C and stirred for 3 hours before cooling down. When the temperature drops to 60°C, add 0.15 parts of hydroquinone, 0.6 parts of N,N dimethyl-p-toluidine, 0.6 parts of cobalt isooctanoate, 1 part of polyethylene micropowder wax and 3 parts of fumed silica. After continuing to cool down to 40°C, filter and package to obtain component A resin liquid.

Embodiment 3

[0054] Accurately weigh 39.5 parts of methyl methacrylate, 20 parts of butyl acrylate, 10 parts of stearyl acrylate, 2 parts of polyethylene glycol dimethacrylate, and 3 parts of polyethylene glycol dimethacrylate in In the reaction kettle, start stirring and heating. When the temperature rose to 50°C, 17 parts of PMMA molding compound with a mass-average molecular weight of 160,000 were added, and the temperature was controlled at 75°C and stirred for 5 hours before cooling down. When the temperature drops to 60°C, add 0.2 parts of tert-butylhydroquinone, 0.5 parts of N,N-diethylaniline, 1.0 parts of N,N dimethyl-p-toluidine, 0.3 parts of cobalt isooctanoate, poly 1.5 parts of amide micronized wax and 5 parts of organic bentonite. After continuing to cool down to 35°C, filter and package to obtain component A resin liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com