Fettling material for converter as well as preparation and using methods thereof

A technology for repairing furnace materials and converters, which is applied in the manufacture of converters, etc. It can solve the problems of polluting the environment, long sintering time of furnace repair materials, and affecting the production rhythm of steel mills, etc., and achieve the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention is described further below:

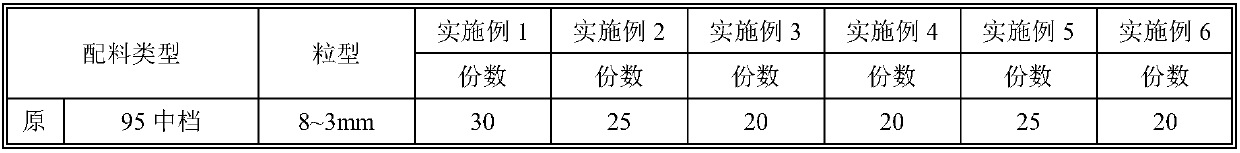

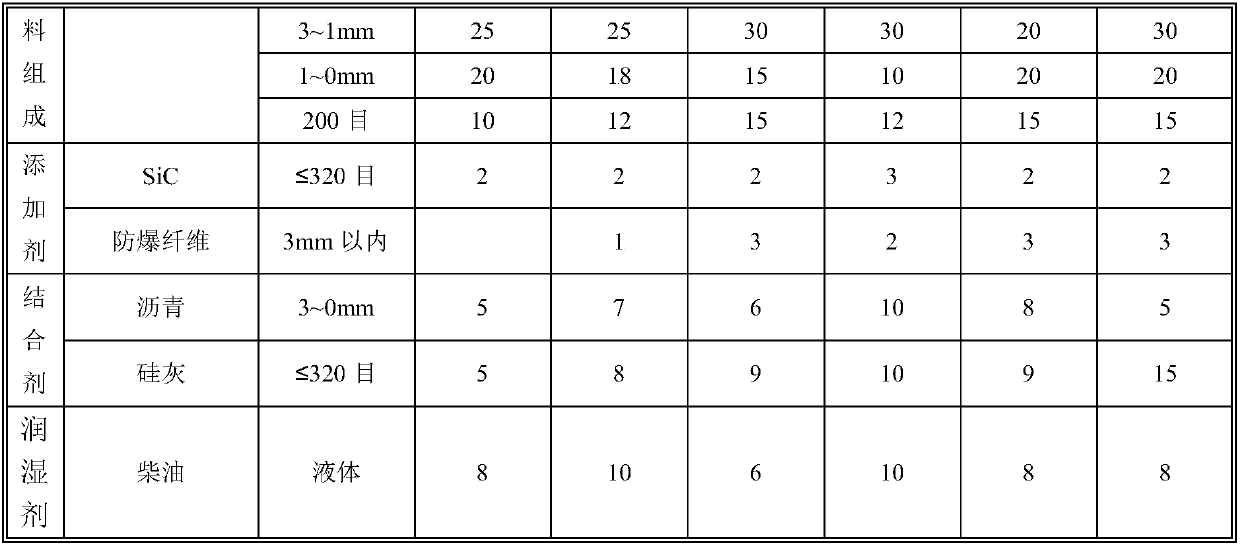

[0016] A repairing material for a converter, which is prepared from the following raw materials in parts by weight: 60-95 parts of magnesia, 10-20 parts of binder, 2-5 parts of additives, and 6-10 parts of wetting agent. The binder is a mixture of asphalt and silica fume.

[0017] The MgO content of the magnesia is more than or equal to 95%; the particle gradation is: 8-3mm is 20-30 parts, 3-1mm is 20-30 parts, 1mm-0 is 10-20 parts, fine powder with a particle size less than or equal to 0.088mm 10-15 servings.

[0018] The weight ratio of asphalt and silica fume in the binder is 1:1-3.

[0019] The additive is one or more than one mixture of SiC or explosion-proof fiber.

[0020] The wetting agent is one or more mixtures of kerosene, diesel or waste engine oil

[0021] The invention discloses a method for preparing furnace repair material for a converter. The method comprises adding magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com