Fiberglass reinforced plastic and manufacturing method thereof

A glass fiber and manufacturing method technology, applied in the field of glass fiber reinforced plastics and its manufacturing, can solve the problems of shipyard cost increase and reputation damage, and achieve the effects of short hardening time, long gelation time, and high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

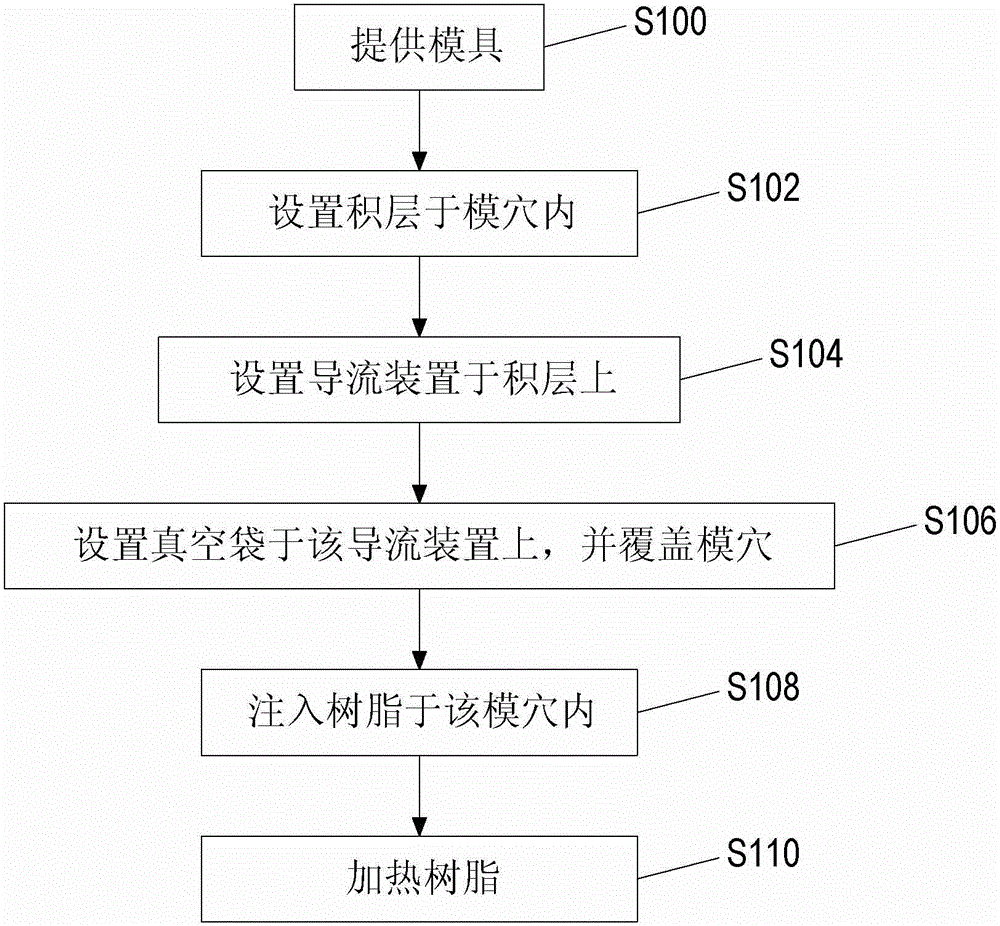

[0034] figure 1 It is a flowchart of a manufacturing method of glass fiber reinforced plastic according to an embodiment of the present invention. The manufacturing method of the glass fiber reinforced plastic comprises the following steps:

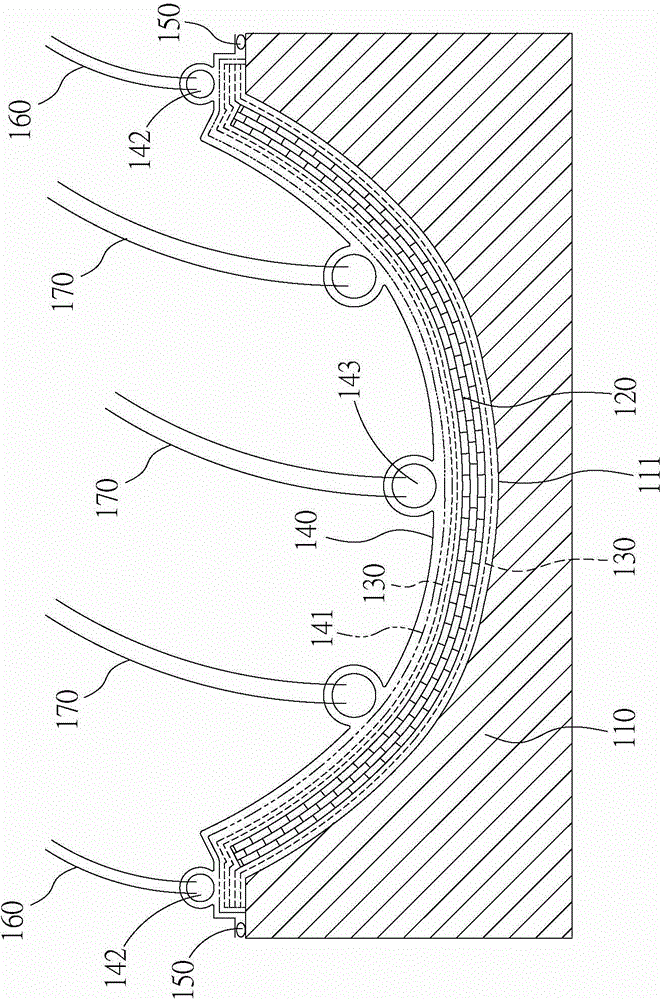

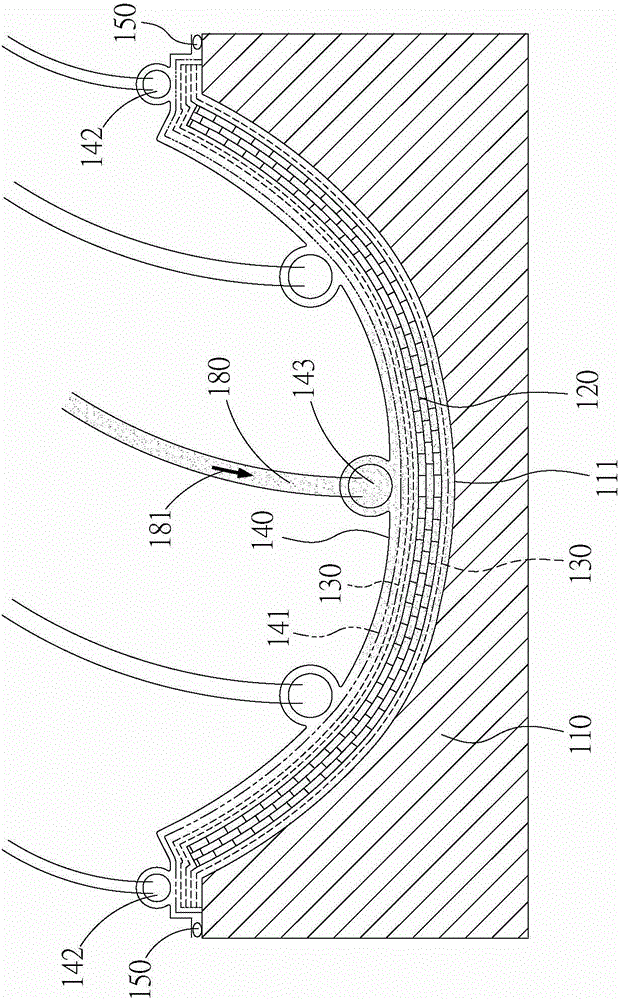

[0035] Step S100: providing a mold. Please also see figure 2 , in this step, the mold 110 includes a mold cavity 111, and the mold cavity 111 is a part of the shape of the glass fiber reinforced plastic.

[0036]Step S102: setting the laminate in the mold cavity. In this step, the laminate can be composed of a core material and / or a fiber material, that is, the laminate disposed in the mold cavity 111 can be the core material 120, the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Barcol hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com