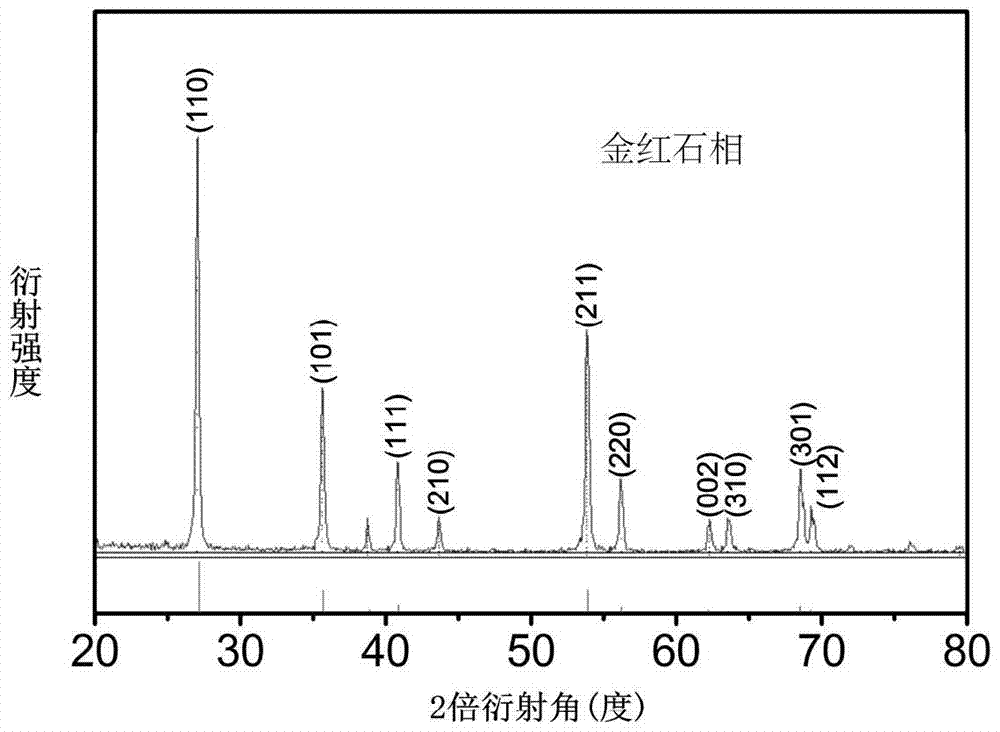

A kind of method that sol-gel method prepares rutile titanium dioxide nano film

A rutile titanium dioxide, sol-gel method, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc. The problem of high raw material waste rate, to achieve the effect of stable structure, long gel time and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

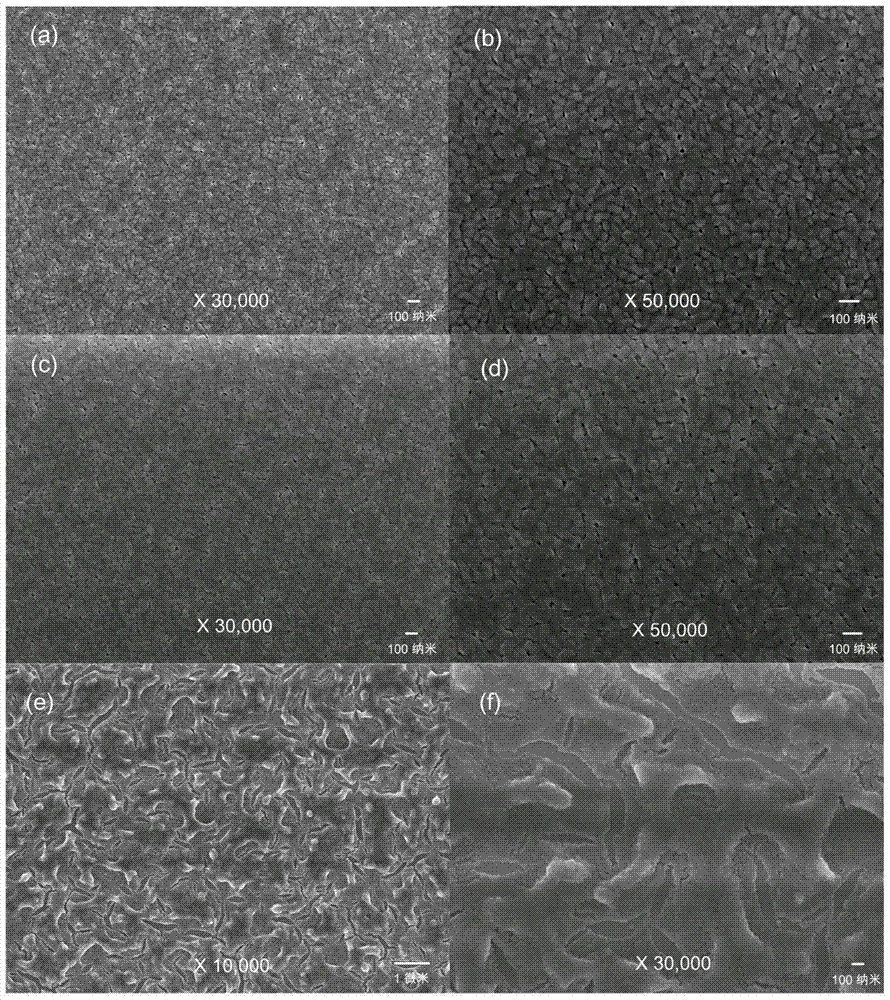

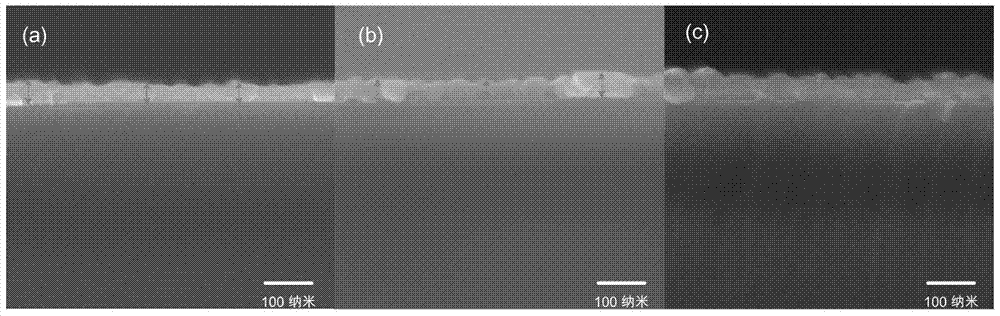

Embodiment 1

[0017] A kind of sol-gel method prepares the method for rutile titanium dioxide nano film, specifically comprises the following steps:

[0018] Step 1: Tetrabutyl titanate (Ti(OBu) 4 ) is a solute, and the mixed solution of monoethanol ammonia, ethylene glycol methyl ether and acetone is a solvent, and the concentration of tetrabutyl titanate for preparation is a precursor solution of 0.1mol / L; wherein, monoethanol ammonia, ethylene glycol methyl ether The volume ratio with acetone is 1:1:0.5;

[0019] Step 2: Add acetylacetone to the precursor solution obtained in step 1 as a chelating agent, glycerol as a tackifier, and magnetically stir at room temperature to obtain a transparent and uniform sol; wherein, the molar ratio of tetrabutyl titanate to acetylacetone It is 1:1, and the volume percentage of glycerol is 5%;

[0020] Step 3: Spin-coat the sol obtained in Step 2 on the cleaned silicon wafer at a spin-coating speed of 2000 rpm, and then dry it in an oven at 200°C to ...

Embodiment 2

[0022] A kind of sol-gel method prepares the method for rutile titanium dioxide nano film, specifically comprises the following steps:

[0023] Step 1: Tetrabutyl titanate (Ti(OBu) 4 ) is a solute, and the mixed solution of monoethanol ammonia, ethylene glycol methyl ether and acetone is a solvent, and the concentration of tetrabutyl titanate for preparation is a precursor solution of 0.2mol / L; wherein, monoethanol ammonia, ethylene glycol methyl ether The volume ratio with acetone is 1:1:0.5;

[0024] Step 2: Add acetylacetone to the precursor solution obtained in step 1 as a chelating agent, glycerol as a tackifier, and magnetically stir at room temperature to obtain a transparent and uniform sol; wherein, the molar ratio of tetrabutyl titanate to acetylacetone It is 1:3, and the volume percentage of glycerol is 5%;

[0025] Step 3: Spin-coat the sol obtained in Step 2 on the cleaned silicon wafer at a spin-coating speed of 3000 rpm, and then dry it in an oven at 275°C to ...

Embodiment 3

[0027] A kind of sol-gel method prepares the method for rutile titanium dioxide nano film, specifically comprises the following steps:

[0028] Step 1: Tetrabutyl titanate (Ti(OBu) 4 ) is a solute, and the mixed solution of monoethanol ammonia, ethylene glycol methyl ether and acetone is a solvent, and the concentration of tetrabutyl titanate for preparation is a precursor solution of 0.4mol / L; wherein, monoethanol ammonia, ethylene glycol methyl ether The volume ratio with acetone is 1:1:0.5;

[0029] Step 2: Add acetylacetone to the precursor solution obtained in step 1 as a chelating agent, glycerol as a tackifier, and magnetically stir at room temperature to obtain a transparent and uniform sol; wherein, the molar ratio of tetrabutyl titanate to acetylacetone It is 1:2, and the volume percentage of glycerol is 5%;

[0030] Step 3: Spin-coat the sol obtained in Step 2 on the cleaned silicon wafer at a spin-coating speed of 2000 rpm, and then dry it in an oven at 200°C to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com