Seawater-based polyacrylamide high-temperature gel profile control system

A polyacrylamide, seawater-based technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high salinity and high calcium and magnesium ion concentration, unclear adaptability, unsatisfactory, and difficult to obtain, etc. Achieve the effect of enhancing oil recovery, improving injection efficiency, and long gelling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

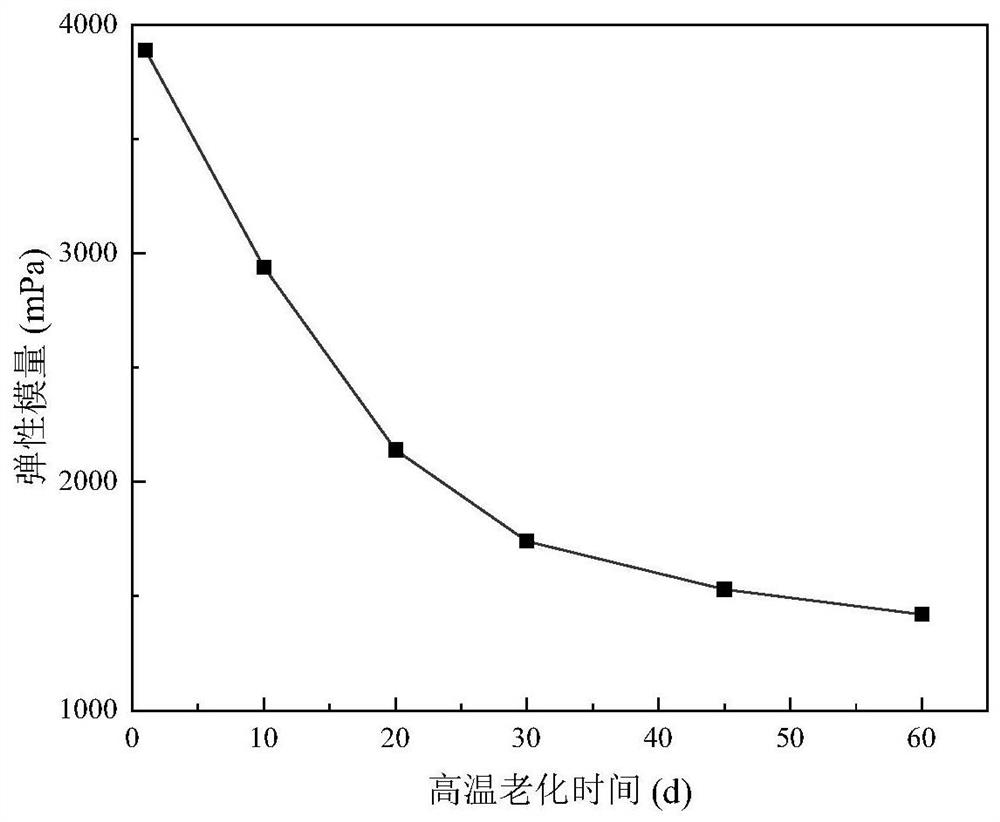

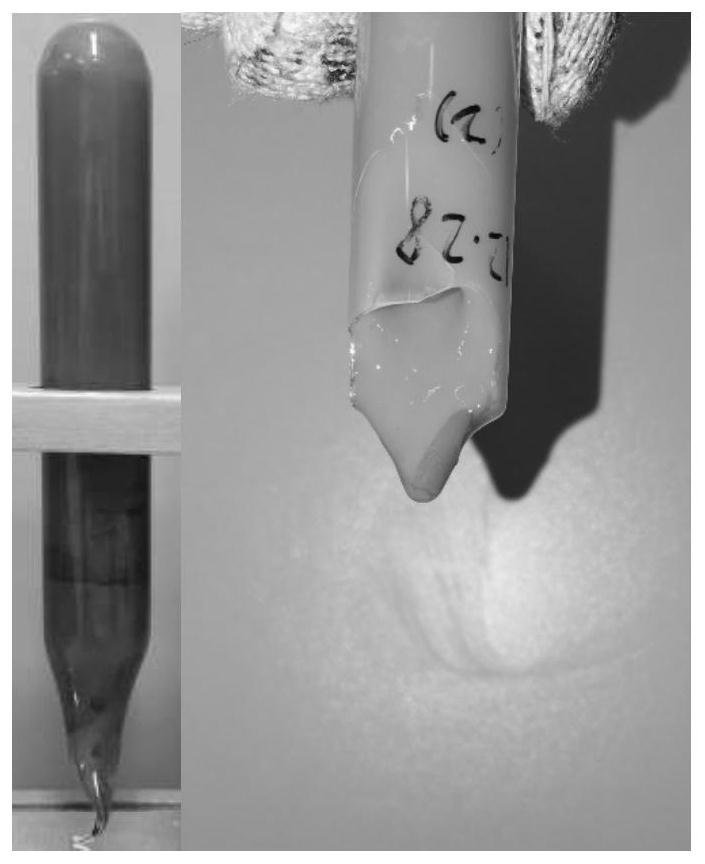

Embodiment 1

[0039] Add 0.8g of non-ionic polyacrylamide, 0.3g of urotropine, 0.3g of resorcinol, and 0.3g of high-temperature stabilizer in sequence while stirring in 98.3g of simulated seawater, and keep stirring until uniform to obtain the gelation of the profile control system solution. Its composition is 0.8% nonionic polyacrylamide by mass fraction, 0.3% urotropine, 0.3% resorcinol, 0.3% high-temperature stabilizer and 98.3% simulated seawater, and the jelly is at 90 The gelling time at ℃ is 26h, and the gelling strength is 10200mPa.

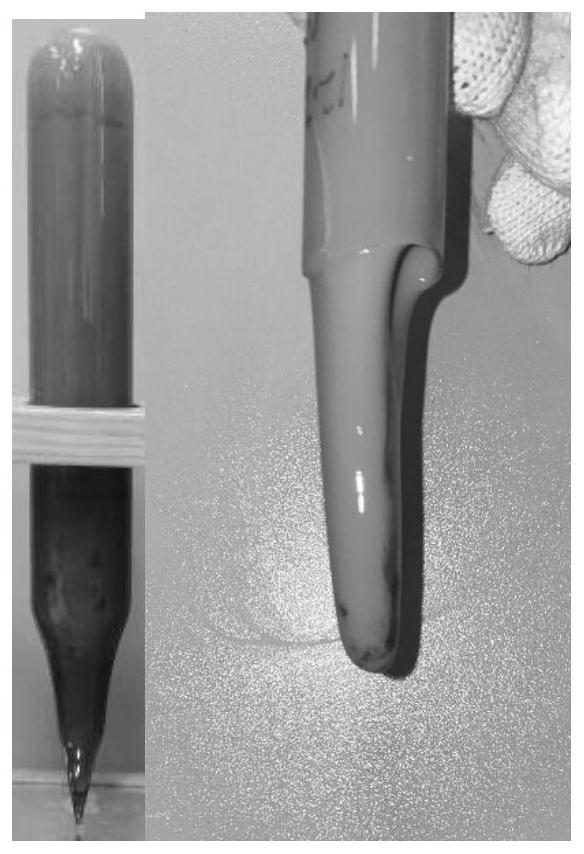

Embodiment 2

[0041] Add 0.8g of non-ionic polyacrylamide, 0.3g of urotropine, 0.3g of resorcinol, and 0.3g of high-temperature stabilizer in sequence while stirring in 98.3g of simulated seawater, and keep stirring until uniform to obtain the gelation of the profile control system solution. Its composition is 0.8% nonionic polyacrylamide by mass fraction, 0.3% urotropine, 0.3% resorcinol, 0.3% high-temperature stabilizer and 98.3% simulated seawater, and the jelly is at 120 The gelling time at ℃ is 11.5h, and the gelling strength is 8620mPa.

Embodiment 3

[0043] Add 0.8g of non-ionic polyacrylamide, 0.3g of urotropine, 0.3g of resorcinol, and 0.3g of high-temperature stabilizer in sequence while stirring in 98.3g of simulated seawater, and keep stirring until uniform to obtain the gelation of the profile control system solution. Its composition is 0.8% nonionic polyacrylamide by mass fraction, 0.3% urotropine, 0.3% resorcinol, 0.3% high-temperature stabilizer and 98.3% simulated seawater, and the jelly is at 130 The gelling time at ℃ is 9h, and the gelling strength is 7530mPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

| drag coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com