Long-acting special controlled release fertilizer for corn and preparation method thereof

A technology for corn-specific, controlled-release fertilizers, applied in applications, fertilization devices, fertilizer mixtures, etc., can solve the problems of inability to meet the needs of corn nutrients, complex slow-release fertilizer preparation process, poor adhesion and sealing continuity, etc. Achieve the effects of low cost, lower fertilizer price, and less land occupation for the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

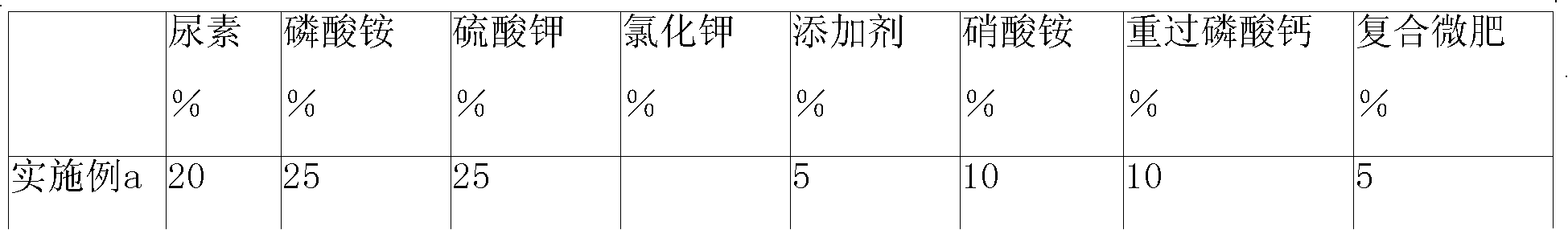

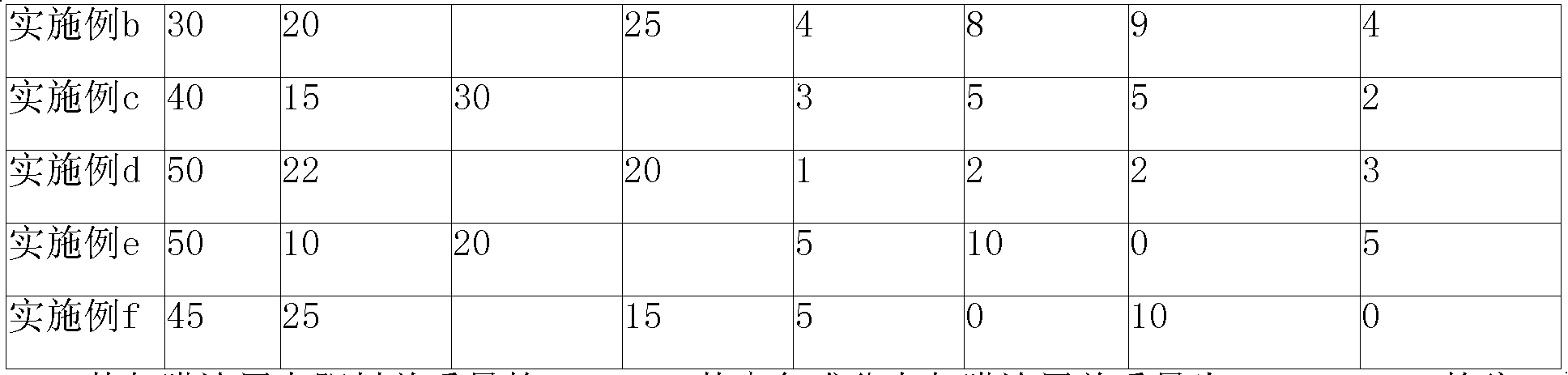

Examples

Embodiment 1

[0029] Embodiment 1: the nitrogen fertilizer in the special controlled-release fertilizer for long-acting corn is urea, ammonium nitrate, ammonium sulfate; Phosphate fertilizer is superphosphate, monoammonium phosphate, diammonium phosphate; Fertilizer zinc sulfate, ferrous sulfate, manganese sulfate, ammonium molybdate, etc. The nutrient ratio is: 4:1:2, and the total nutrient content is 40±1%. The special controlled-release fertilizer for long-acting corn can be prepared by the following steps:

[0030] (1), prefabricated fertilizer core: 127.3kg nutrient content is 12-55-0 powdery monoammonium phosphate, 280.0kg K2O content is 50% potassium sulfate, 250kg powdery urea, 17.2kg additives are put into stirring and mixing In a container, mix well.

[0031] Send the uniformly mixed powdered monoammonium phosphate, potassium sulfate, powdered urea and additives into the granulation drum.

[0032] Melt 325.5kg of urea, spray it into the fertilizer mixture in the granulation cyl...

Embodiment 2

[0038] Embodiment 2: The nutrient ratio is: 2.2:1:1, the total nutrient content is 35±1%, and the long-acting corn-specific controlled-release fertilizer containing the trace element zinc can be prepared by the following steps.

[0039] (1), prefabricated fertilizer core: 100kg nutrient content is the powdered monoammonium phosphate of 12-55-0, the K2O content of 166.70kg is the potassium chloride of 60%, the powder of 128.6kg phosphorus pentoxide content is 35% Heavy superphosphate, 103.0kg of ammonium nitrate with 34% nitrogen content, 65.0kg of ammonium sulfate with 20% nitrogen content, 69.6kg of powdered urea, 41.7kg of zinc sulfate with 24% zinc content, and 25.4kg of additives mixed evenly. The above-mentioned fertilizers that have been mixed evenly are sent into the granulation drum.

[0040] Melt 300.0kg of urea, and use spray granulation process to spray all the melted 300kg of urea into the fertilizer mixture in the granulation tube, and control to achieve a suitabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com