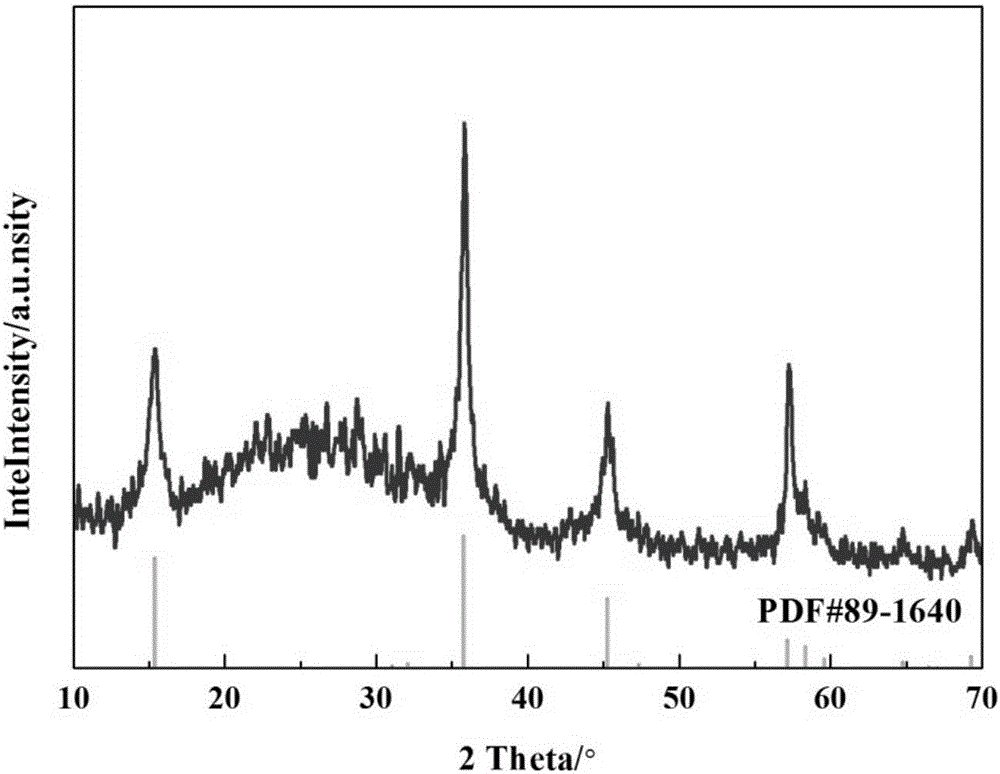

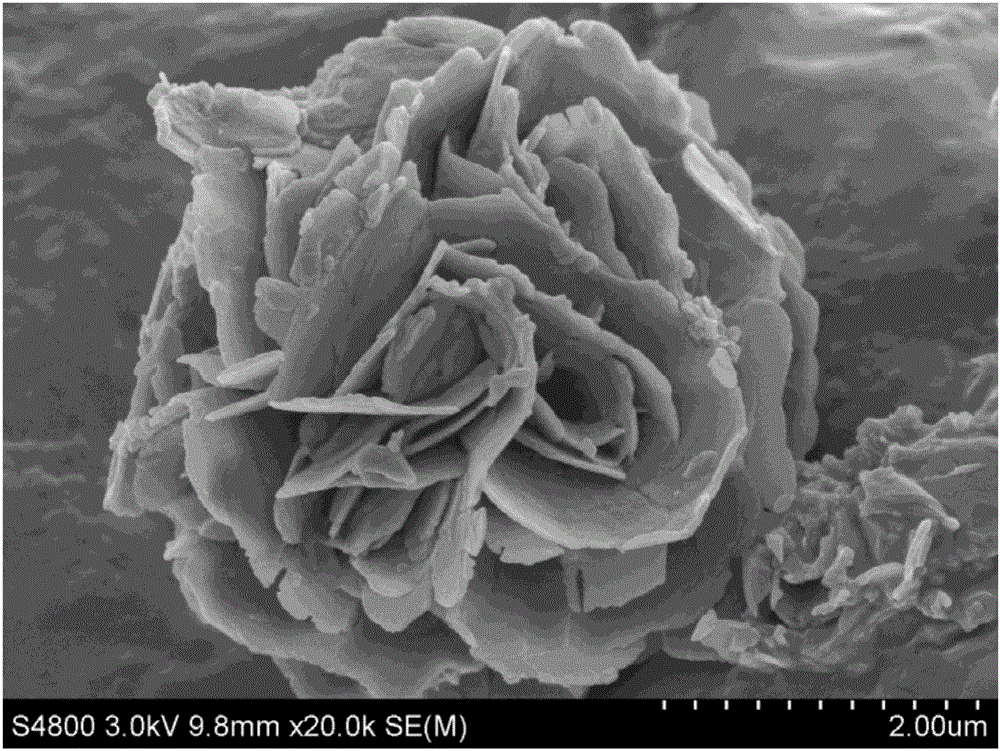

Preparation method and application of nanosheet self-assembled microflower-shaped VS2

A self-assembly and nanosheet technology, applied in nanotechnology, chemical instruments and methods, vanadium compounds, etc., to achieve high purity, uniform chemical composition, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A nanosheet self-assembled microflower-like VS 2 The preparation method comprises the following steps:

[0023] Step 1: Weigh the vanadium source and sulfur source and dissolve them in deionized water, control the vanadium-sulfur molar ratio to 1:1-1:6, stir magnetically for 10-60 minutes to obtain a semi-clear solution A, and the concentration of the vanadium source is 0.1 ~0.5mol / L. Vanadium source is one or more of sodium vanadate, ammonium metavanadate, vanadium pentoxide and potassium metavanadate; sulfur source is thioacetamide, sodium sulfide, ammonium sulfide, sodium diethylthiocarbamate And one or more of the elemental sulfur.

[0024] Step 2: Prepare 1-4 mol / L sodium hydroxide solution B, and then add solution B dropwise to solution A until the pH value of the solution reaches 11-14, and obtain solution C. During this process, solution A needs to be continuously magnetically stirred, and the pH value must be controlled between 11 and 14, so that the presenc...

Embodiment 1

[0029] Step 1: Weigh sodium metavanadate and thioacetamide and dissolve them in deionized water, control the molar ratio of vanadium to sulfur to 1:1, and stir magnetically for 10 minutes to obtain semi-clear solution A. At this time, the concentration of vanadium source is 0.2mol / L.

[0030] Step 2: prepare 3 mol / L sodium hydroxide solution B, then add solution B dropwise to solution A until the pH value of the solution reaches 13, and obtain solution C. During this process, solution A needs to be constantly stirred by magnetic force.

[0031] Step 3: Pour the solution C into the reaction liner, then fix the liner in the outer kettle and place it in a homogeneous reactor, and then react at 160°C for 24 hours under the condition of 10r / min.

[0032] Step 4: Take out the cooled product after the reaction, collect the product after 3 times of water washing and 3 times of alcohol washing, and dry it at 60°C for 12 hours to obtain the nanosheet self-assembled micro flower-shaped...

Embodiment 2

[0036] Step 1: Weigh sodium metavanadate and thioacetamide and dissolve them in deionized water, control the molar ratio of vanadium to sulfur to 1:3, and stir magnetically for 20 minutes to obtain a semi-clear solution A. At this time, the concentration of vanadium source is 0.1mol / L.

[0037] Step 2: prepare 1 mol / L sodium hydroxide solution B, then add solution B dropwise to solution A until the pH value of the solution reaches 11, and obtain solution C. During this process, solution A needs to be constantly stirred by magnetic force.

[0038]Step 3: Pour the solution C into the reaction liner, then fix the liner in the outer kettle and place it in a homogeneous reactor, and then react at 120° C. for 6 hours under the condition of 5 r / min.

[0039] Step 4: Take out the cooled product after the reaction, collect the product after 4 times of water washing and 4 times of alcohol washing, and dry it at 40°C for 18 hours to obtain the nanosheet self-assembled micro flower-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

| Specific volume | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com