High-performance directional heat conduction copper-base diamond composite material and preparation method thereof

A technology of directional heat conduction and composite materials, which is applied in the direction of metal material coating process, semiconductor devices, semiconductor/solid device components, etc., to achieve the effects of high melting point, easy welding, good ductility and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

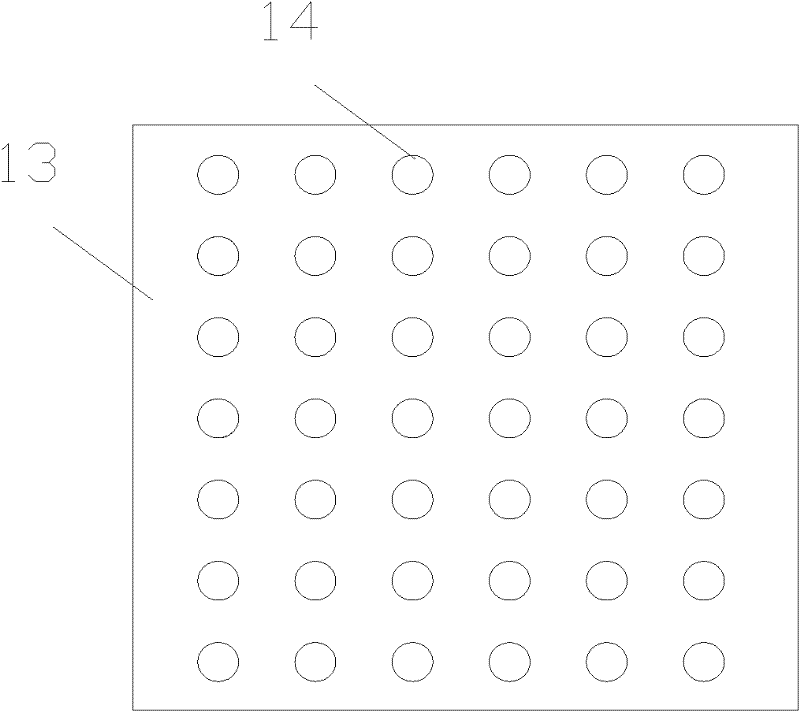

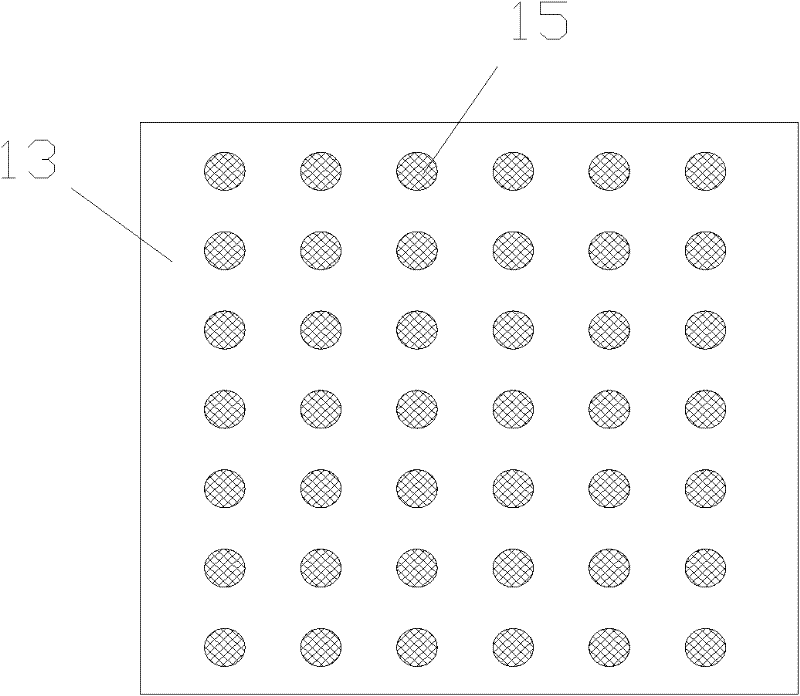

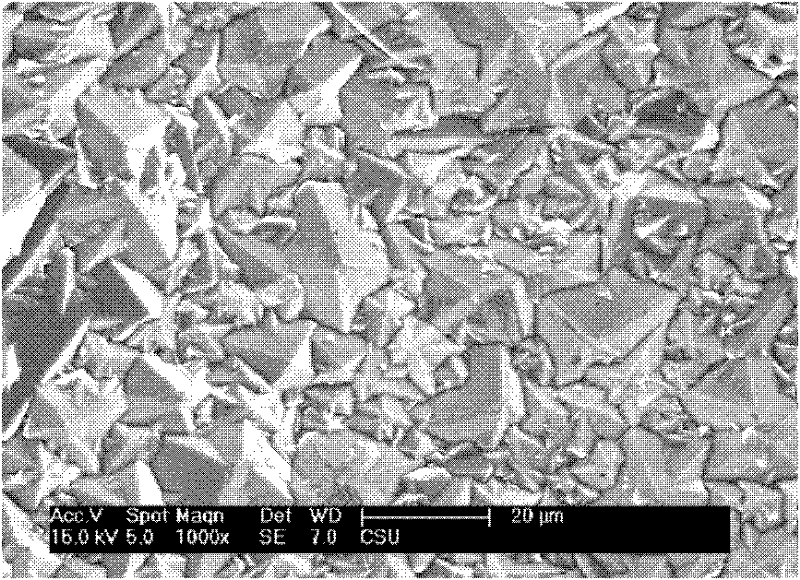

[0043] First, use the copper plate as the copper substrate 13, such as figure 1 As shown, a series of columnar through-holes 14 parallel to each other are drilled on the copper base 13. The spacing of the columnar through-holes 14 is 0.5-50 mm, wherein the thickness of the copper base 13 is 0.1-30 mm, and the diameter of the columnar through-holes 14 is 0.5-50 mm. 10mm; Then, adopt chemical vapor deposition technology to deposit diamond rod 15 in columnar through hole, make diamond fill all columnar through hole 14, form columnar diamond array, as figure 2 as shown, image 3 It is a schematic diagram of diamond SEM image of copper-based diamond composite obtained by hot wire chemical vapor deposition.

[0044] Before chemical vapor deposition, the sample was ultrasonically treated with diamond powder acetone suspension for 5-60 minutes, the surface of the sample was cleaned with acetone and dried with a fan, and then the diamond film was prepared by hot wire chemical vapor d...

Embodiment 2

[0046] First, if Figure 4 As shown, a tungsten wire is used as a linear core 16, and a continuous diamond film 17 is grown on the surface of the core by chemical vapor deposition technology, thereby obtaining a cylindrical cored diamond rod 18. The diameter of the linear core 16 is 0-30mm, and the thickness of the diamond rod is 0.25 ~ 5mm, such as Figure 5 as shown, Image 6 The SEM image of the diamond rod surface of the cored diamond rod, Figure 7 It is the SEM image of the diamond rod cross-section of the cored diamond rod; then, with the copper plate as the copper substrate 13, a series of parallel columnar through holes 14 are drilled on the copper substrate 13, and the spacing of the columnar through holes 14 is 0.5~50mm. The diameter of the hole 14 matches the cylindrical cored diamond rod 18, wherein the thickness of the copper substrate 13 is 0.1 to 100 mm; then, the cylindrical cored diamond rod 18 is pressed into the columnar through hole 14 of the copper subs...

Embodiment 3

[0049] First, if Figure 4 As shown, with filamentary or rod-shaped copper, tungsten, molybdenum or titanium as linear core 16, adopt chemical vapor deposition technology to grow continuous diamond film 17 on the core surface, thereby obtain cylindrical cored diamond rod 18, linear core 16 The diameter is 0.1 ~ 30mm, the thickness of the diamond film is 0.25 ~ 5mm, such as Figure 5 Shown; Then, with the thin copper sheet 19 as the substrate, a series of parallel columnar through holes are drilled on the substrate, the diameter of the hole matches the cylindrical cored diamond rod 18, and the thickness of the thin copper sheet 19 is 0.0001 ~ 1mm; then ,like Figure 9 As shown, the cylindrical cored diamond rod 18 is pressed into the columnar through hole of the thin copper sheet 19, one end of the cylindrical cored diamond rod 18 is flush with the thin copper sheet 19, and the other end is higher than the thin copper sheet 19, and then passed Electrodeposition technology uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com