Preparation method of vertically arrayed graphene thin films

A technology of graphene film and array, which is applied in the field of large-scale graphene film production, can solve the problem of less heat, and achieve the effect of solving the problem of excessively high hot spot temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

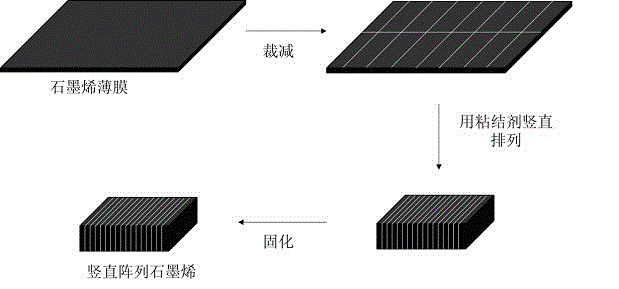

[0025] Such as figure 1 As shown, the graphene film preparation process is as follows, a) the graphene oxide solution is prepared by the modified Hummer method, and vacuum dried; b) the graphene powder is re-infused into the deionized aqueous solution to form a neutral graphene oxide solution; c ) Prepare an A4 paper-sized glass substrate for spin-coating graphene oxide. When the graphene oxide reaches a certain thickness, the graphene oxide film is first dried at room temperature, and then placed in a 95-100° C. L-ascorbic acid solution to reduce the graphene oxide film to obtain a graphene film.

[0026] In order to obtain vertically aligned graphene films, a specific mold container needs to be designed to meet the requirements. The graphene film obtained above is first cut to an appropriate size, and then arranged in a vertical array in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com