Low-filling-capacity and high-heat-conductivity graphene/silicone grease composite material and preparation method thereof

A technology of high thermal conductivity graphite and low filling amount, which is applied in the field of low filling amount and high thermal conductivity graphene/silicone grease composite material and its preparation field, can solve the problems of affecting heat dissipation effect, affecting the fluidity of silicone grease, low thermal conductivity, etc. The effect of improving reliability and service life, reducing interface contact thermal resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

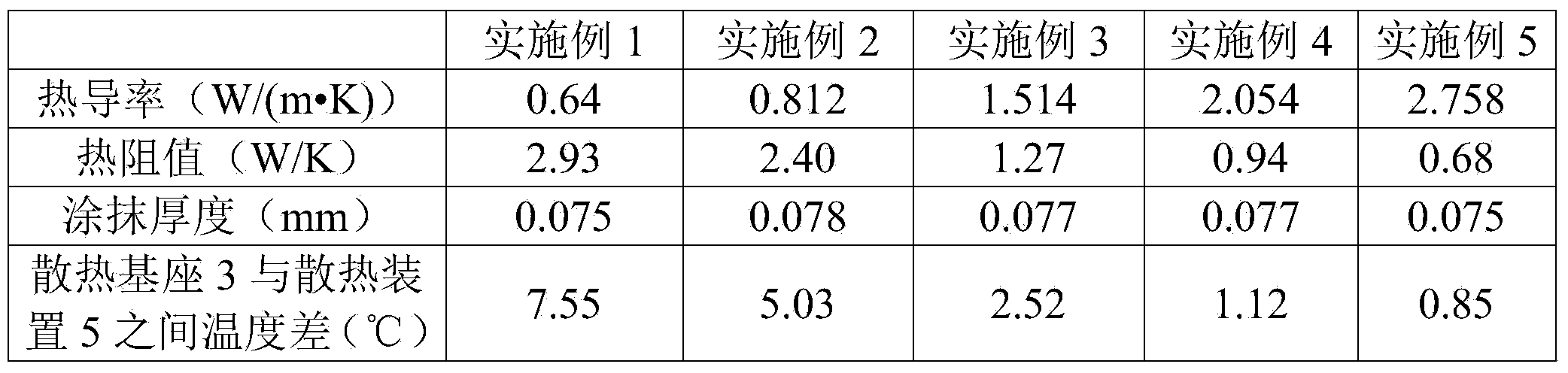

[0022] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, the typical but non-restrictive implementation of the present invention is as follows:

[0023] Concrete processing steps of the present invention are:

[0024] (1) Preparation of reduced graphene oxide sheets: Add 5g of natural flake graphite into 115ml of concentrated sulfuric acid, stir well and add 15g of KMnO 4 , Stir at a low speed for 2.5 hours in a low-temperature and constant-temperature water bath at 3-5°C, then continue stirring for 2 hours in a constant-temperature water bath at 30-35°C, then raise the temperature of the constant-temperature water bath to 80°C and continue stirring; in the range of 60-70°C Inside, when the color of the sample is brownish red, add 250ml of deionized water dropwise at a constant speed. At this time, the color of the sample turns bright red, and then add 50ml of H 2 o 2 Until the color of the sample completely tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com