High-effective integral spray cooling system

A spray cooling, integrated technology, applied in cooling/ventilation/heating transformation, electric solid devices, semiconductor devices, etc., can solve the problems of large heat exchange area, heat transfer temperature difference, increased flow resistance, etc., to reduce heat exchange Area, reduce flow resistance, improve heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

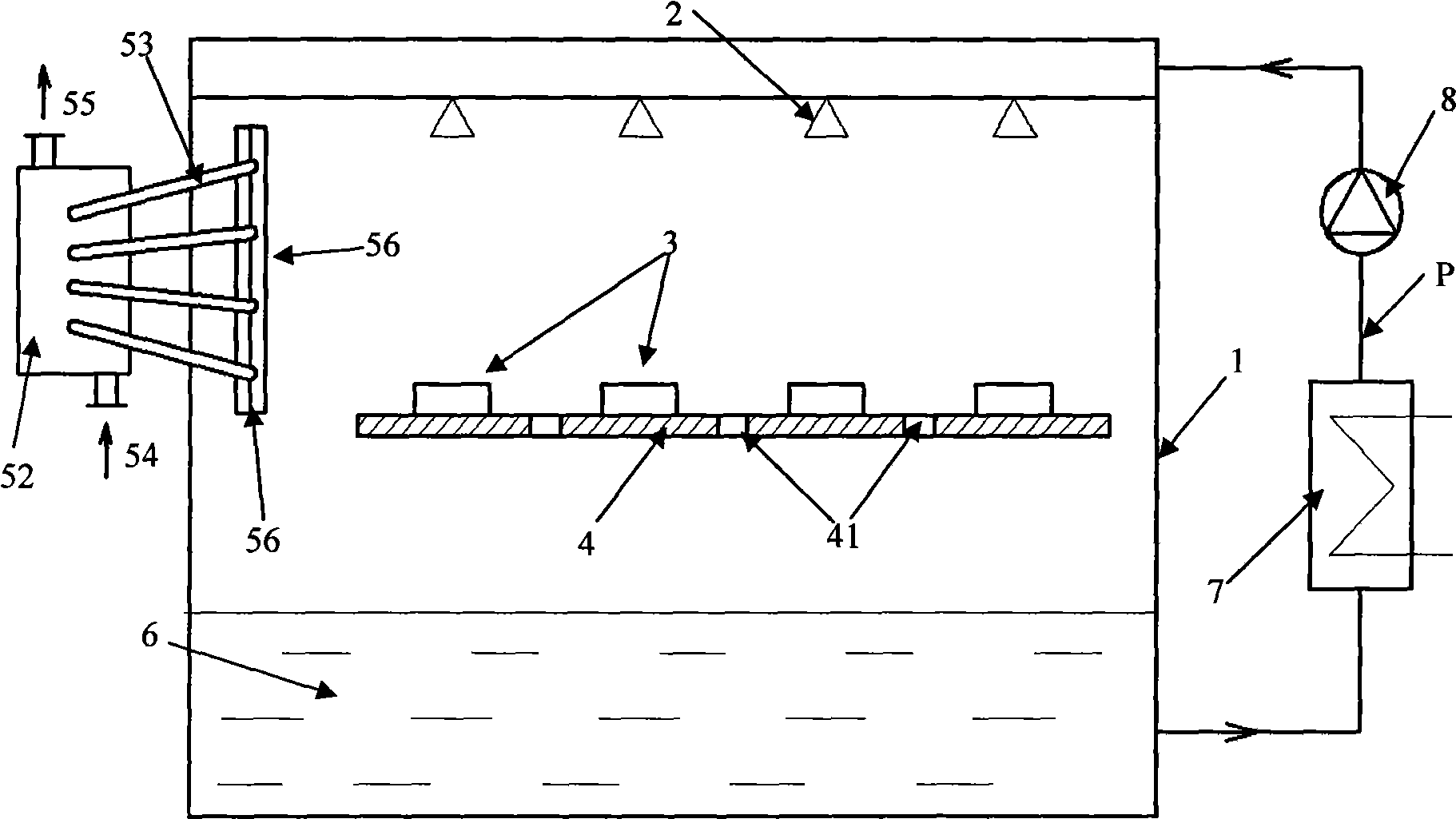

[0023] see figure 1 , figure 2 The high-efficiency integrated spray cooling system includes a spray chamber 1, a heat pipe heat exchanger, a liquid cooler 7, a circulation pump 8 and a system working fluid circulation pipeline P, and a spray mechanism 2 is installed on the top of the spray chamber 1, and an orifice plate is installed in the middle 4. Guide holes 41 are evenly distributed on the orifice plate, electronic components 3 are evenly distributed on the orifice plate 4, and a liquid reservoir 6 is arranged at the bottom, and the liquid reservoir 6 is connected with the liquid cooler 7, the circulation pump 8, And the spray mechanism 2 is connected. A heat pipe heat exchanger is used as a steam condenser.

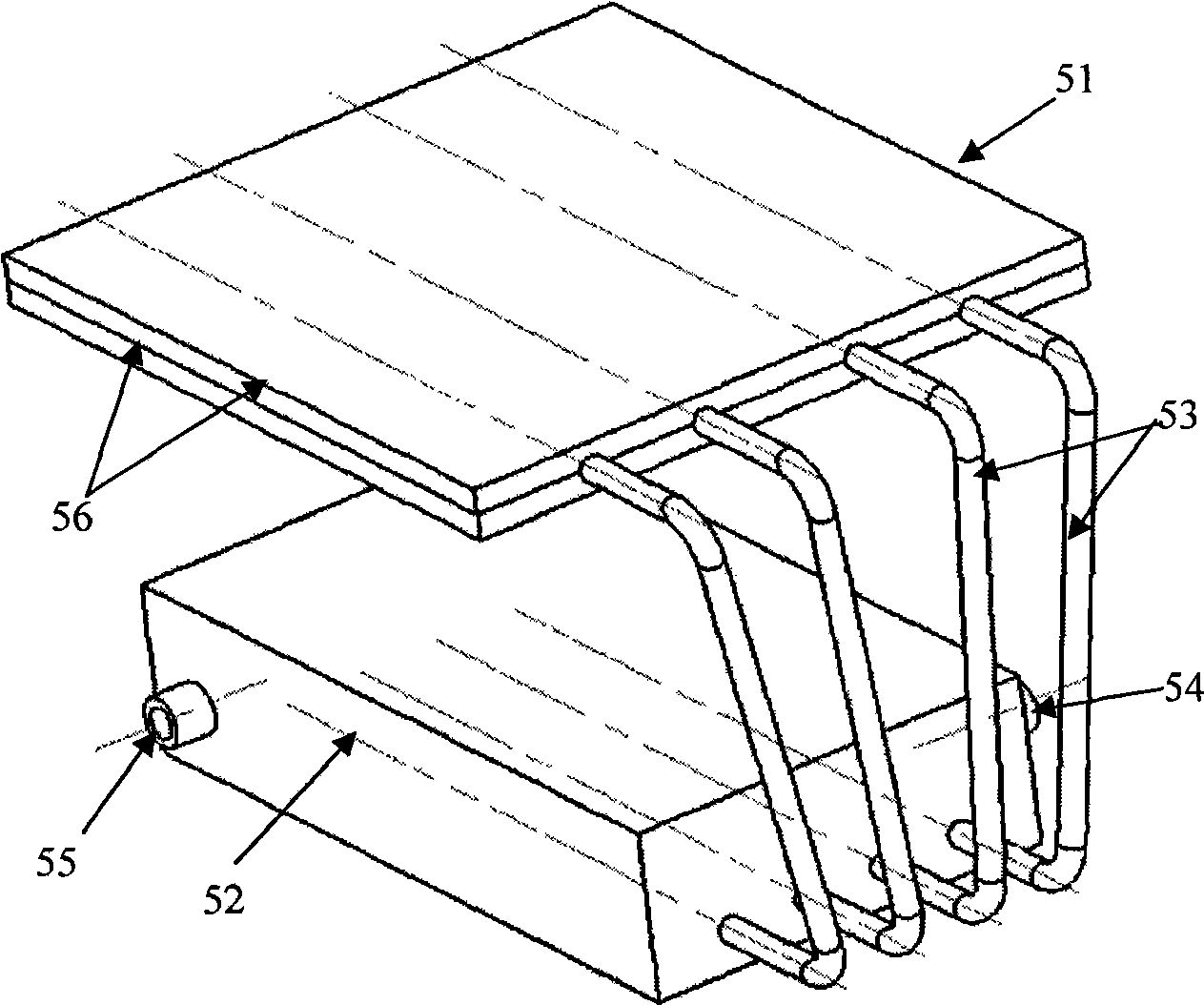

[0024] One end of the heat pipe 53 of the heat pipe heat exchanger is the condensation end 52, and the other end of the heat pipe 53 is the evaporation end 51, which is a steam condenser; the evaporation end is located inside the spray chamber to provide condensa...

Embodiment 2

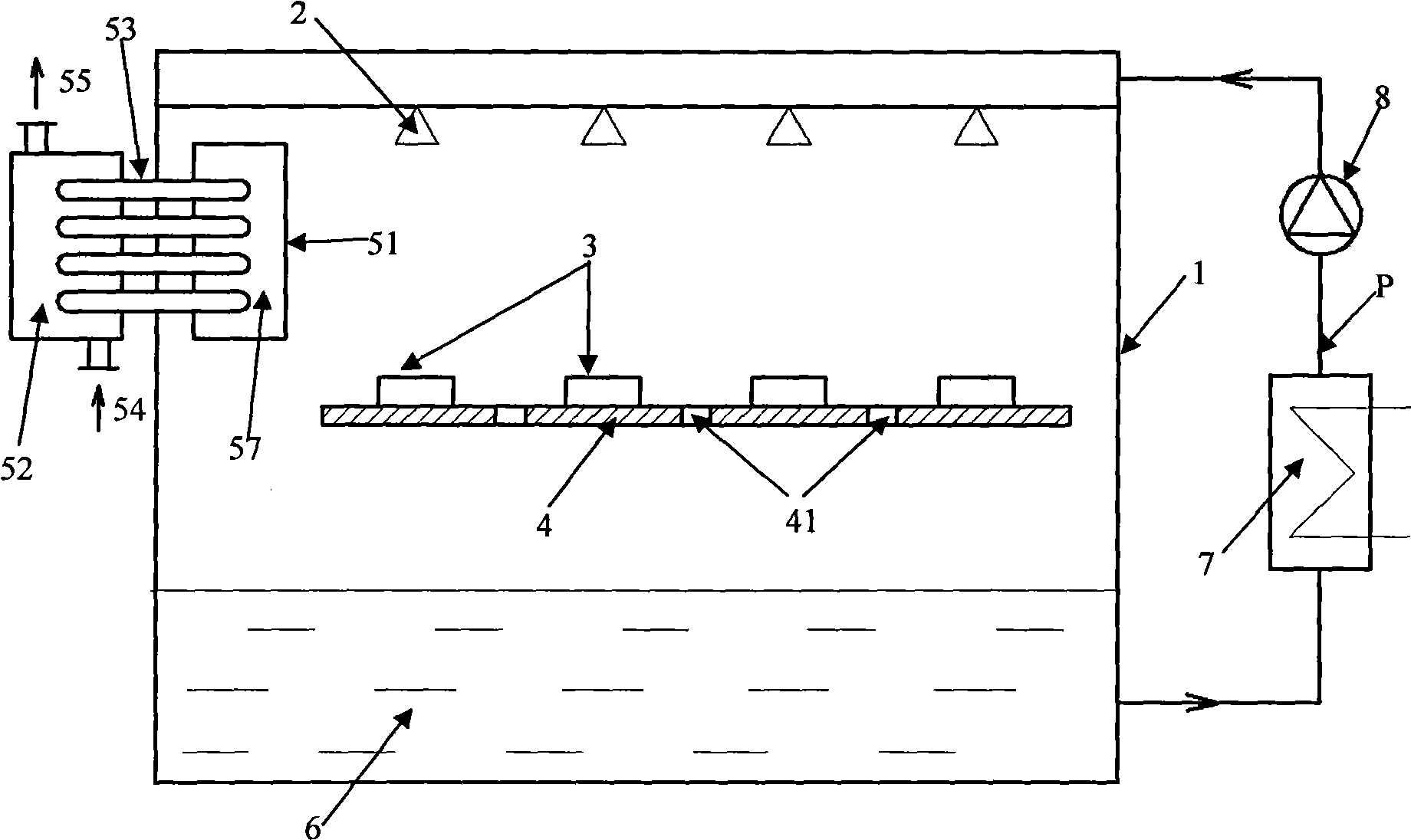

[0031] see image 3 , Figure 4 , the system uses a heat pipe heat exchanger as a steam condenser. The evaporating end 51 of the heat pipe heat exchanger is located inside the spray chamber 1 to provide condensation for the steam; the condensing end 52 of the heat pipe condenser is located outside the spray chamber to remove the condensation and heat dissipation of the steam out of the spray chamber; the heat pipe heat exchanger includes four heat pipes Fins 57 are evenly distributed on the evaporating end 51, and the condensing end 52 is located in the water-cooled shell-and-tube heat exchanger outside the spray chamber. There is a cooling water inlet 54 at the bottom of one side of the water-cooled shell-and-tube heat exchanger, and there is The cooling water outlet 55; the middle part of the heat pipe 53 passes through and is fixed on the side wall of the spray chamber 1, and the joint between the heat pipe and the side wall of the spray chamber can be sealed by means of a...

Embodiment 3

[0035] see Figure 5 , the liquid reservoir 6 and the liquid cooler 7 are combined to form a liquid storage cooler 67, which is arranged at the bottom of the spray chamber 1.

[0036] When the present embodiment works, the working medium cooled by the liquid cooler 7 enters the spray mechanism 2 of the spray chamber 1 after the circulation pump 8 increases the pressure and atomizes, and sprays on the surface of the electronic component 3 to cool and dissipate the surface of the electronic component 3 , the non-vaporized working fluid flows through the surface of the electronic component 3, and flows into the liquid storage cooler 67 through the orifice plate 4; part of the working fluid vaporizes due to absorbing heat from the electronic component 3 and forms steam, which is recondensed into liquid on the surface of the condenser Flow into the liquid storage cooler 67; after the working medium in the storage liquid cooler 67 is cooled to the required temperature by the cooler ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com