Embedded strong-current high-power PCB (Printed Circuit Board) and manufacturing method thereof

A technology of PCB board and manufacturing method, applied in the field of PCB board manufacturing, can solve the problems of large space occupation, high cost, complicated assembly process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

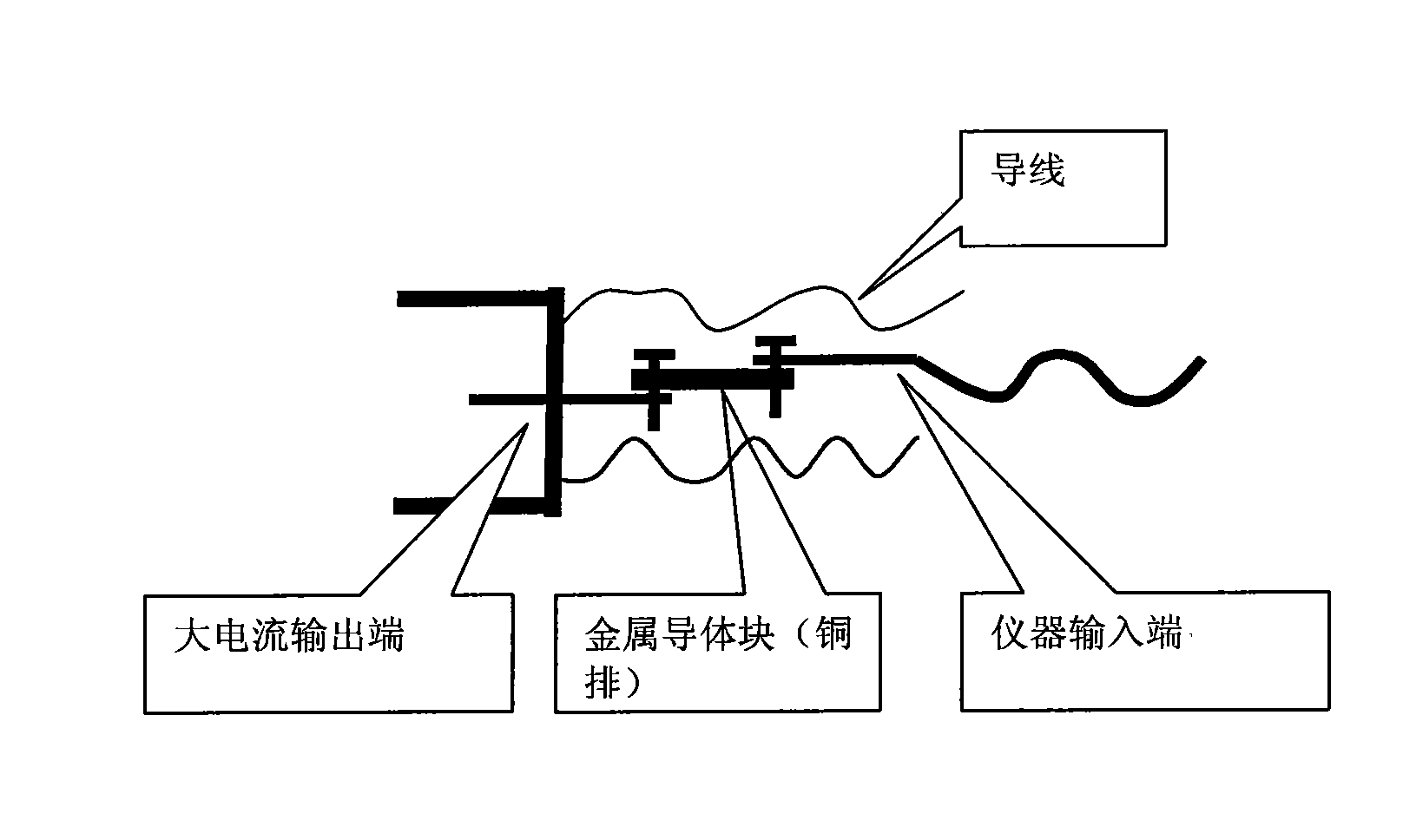

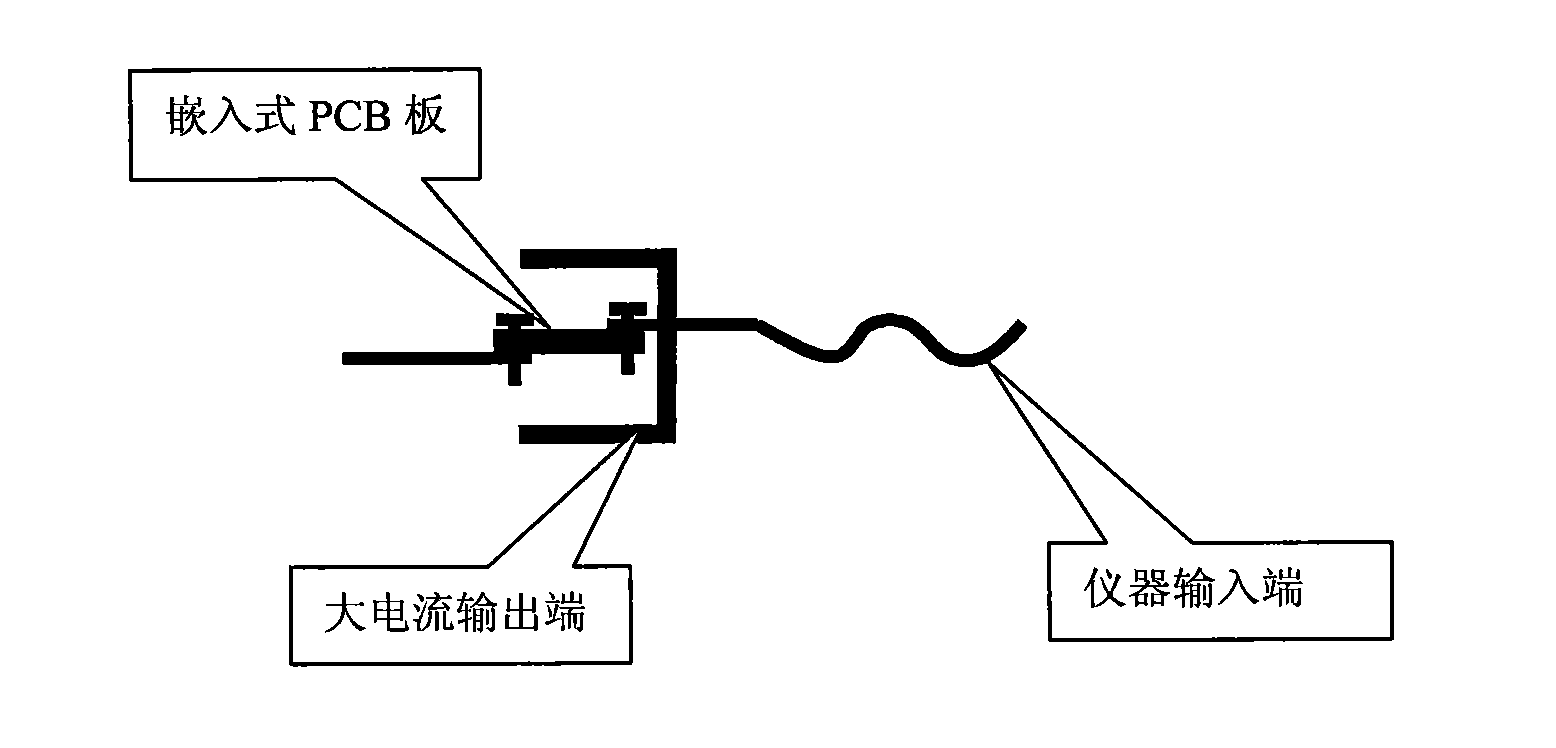

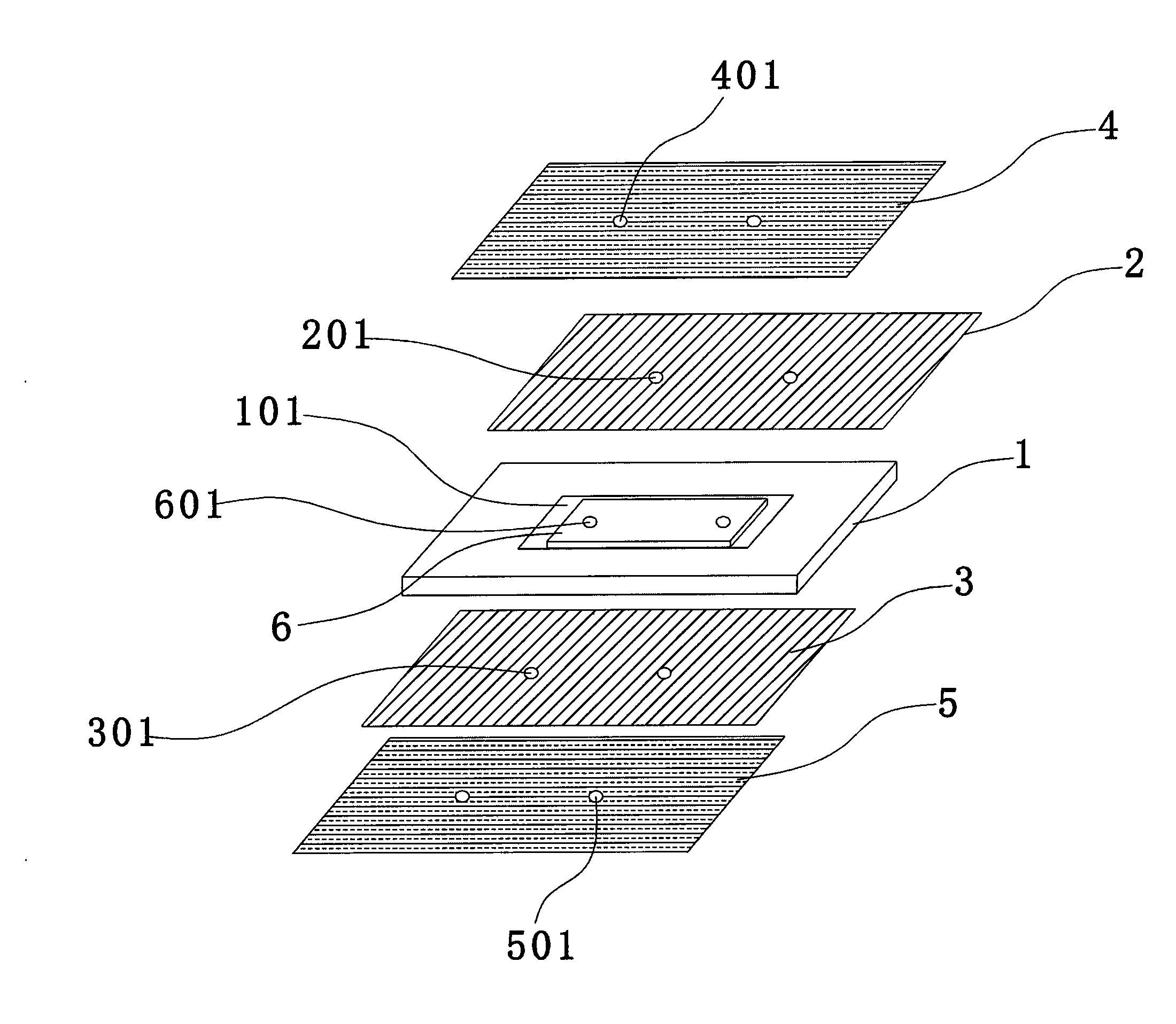

[0031] The core idea of the present invention is: the present invention embeds a conductor structure in the core board of the PCB board, realizes the interconnection between the large current output end and the instrument input end through the conductor structure, and can make the conductor structure and the PCB board Its own circuit design connection to realize the circuit and power control of the instrument.

[0032] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] See figure 2 as shown, figure 2 It is a schematic diagram of the connection between the current output end of the high-current high-power electronic product of the present invention and the instrument input end through an embedded high-current high-power PCB board. Among them, the current output terminal of the current high-current and high-power electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com