Cathode material of composite carbon in use for lithium ion battery and preparation method

一种锂离子电池、负极材料的技术,应用在电极制造、电池电极、二次电池等方向,能够解决性能不尽如人意、放电容量低等问题,达到易于操作、制备工艺简单、成本低廉的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of lithium ion battery composite carbon negative electrode material of the present invention comprises the following steps:

[0030] 1. Add natural flake graphite, microcrystalline graphite, artificial graphite or mesophase carbon microspheres with a particle size of 45 to 500 μm into the high-speed pulverizer of a jet mill, high-pressure pulverizer or rod mechanical pulverizer, and grind at 3000~ Pulverize at a speed of 6000rpm for 10 to 90 minutes to obtain graphite powder;

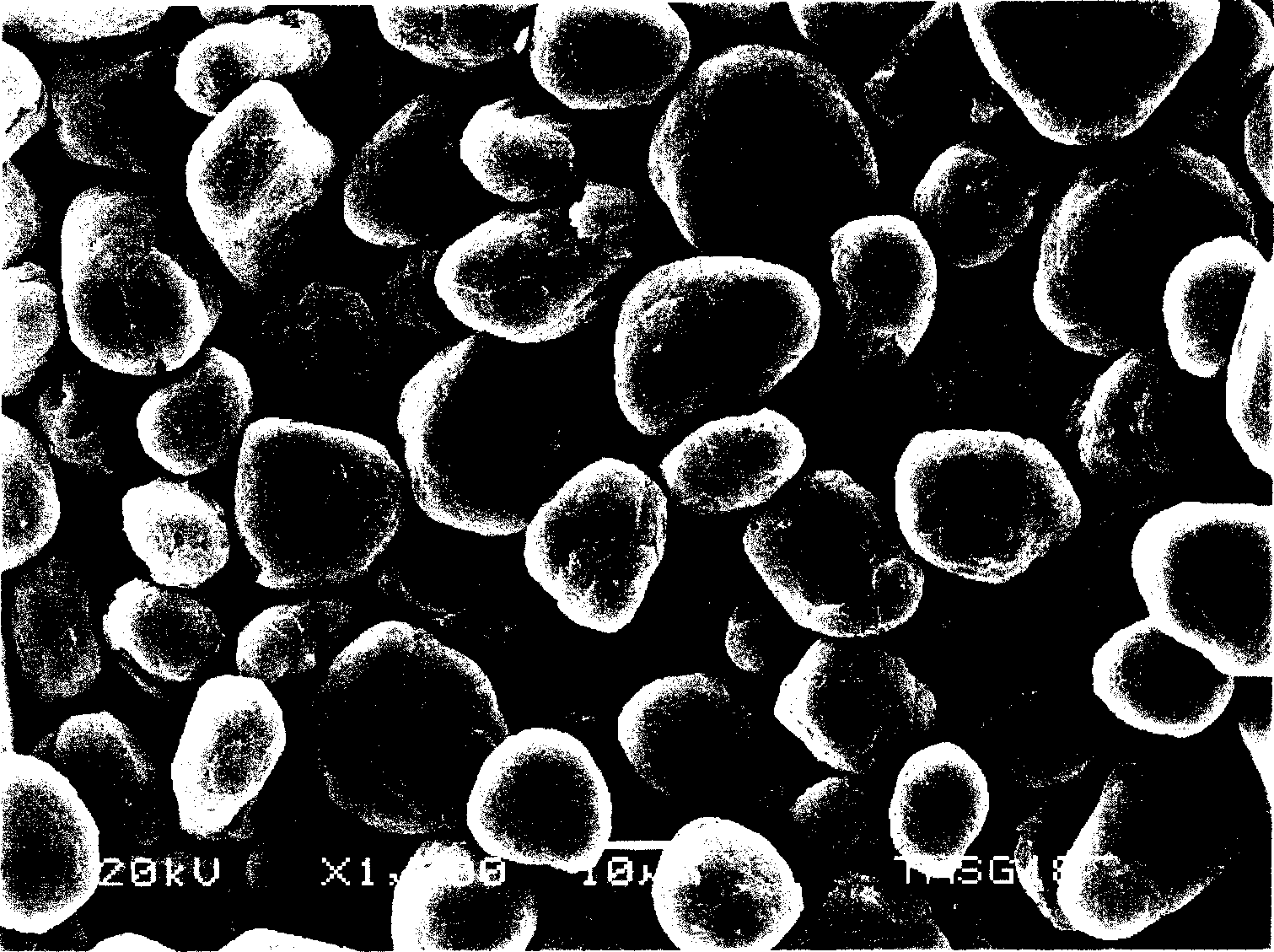

[0031] 2. Add graphite powder to the low-speed impact ball mill, airflow vortex mill, ultrafine mill, ultramicro ball mill, internally classified impact micro-powder mill or pendulum mill for low-speed impact spheroidization In the pulverizer, shape and spheroidize at a speed of 600-3000rpm for 40-180 minutes to obtain spherical graphite;

[0032] 3. The particles smaller than 5μm and larger than 75μm in spherical graphite are removed by airflow classifier, jet classifier,...

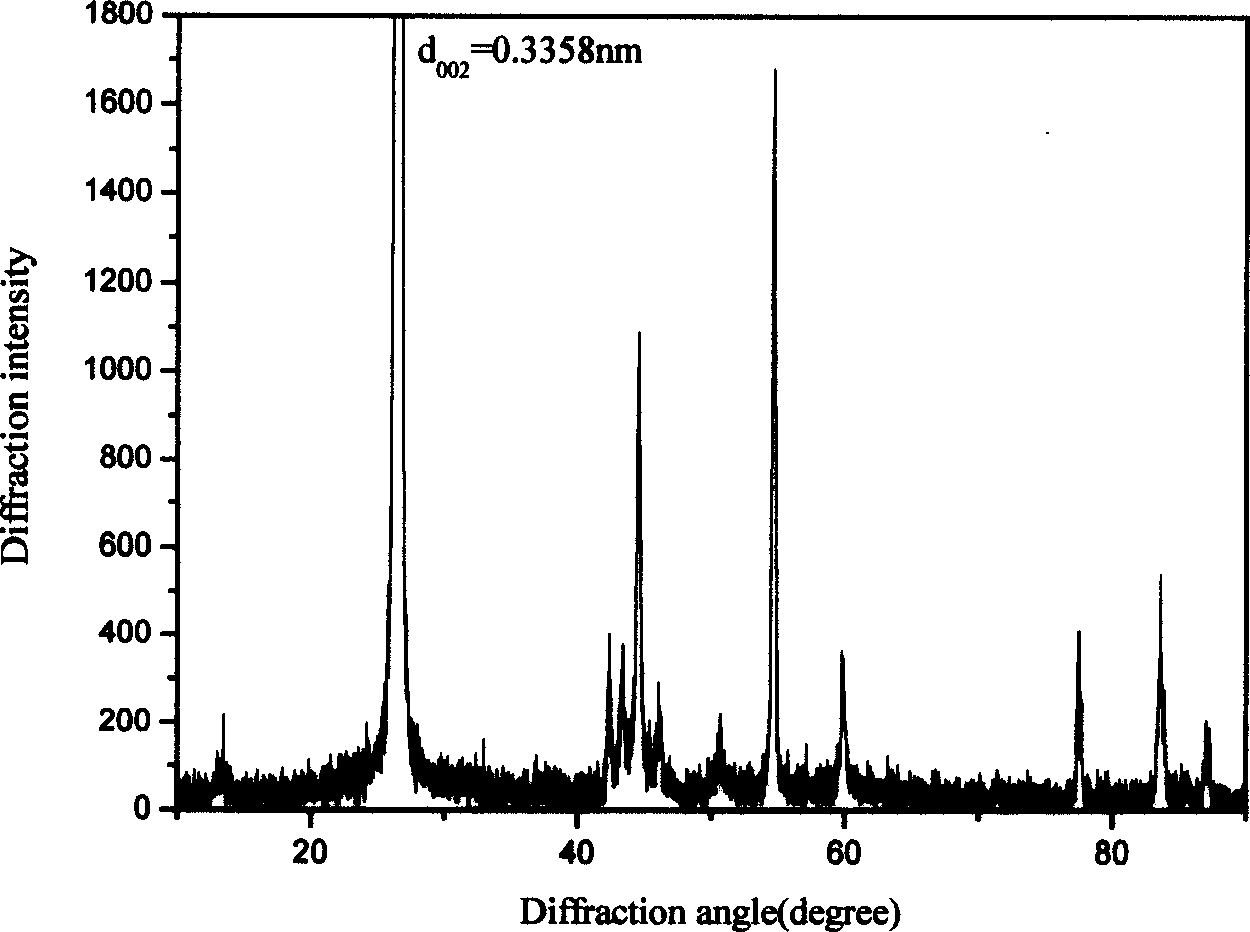

Embodiment 1

[0055] The natural graphite with a particle size of 500 μm and a carbon content of 90% is pulverized by a rotary high-speed pulverizer at a rotation speed of 6000rpm for 10 minutes, and then spheroidized by a low-speed impact-type spheroidizer at a rotation speed of 3000rpm for 40 minutes. After the particle size distribution is 5-75μm, put 100kg of the above-mentioned graphite into the reaction kettle, add 35kg of mixed acid of sulfuric acid and nitric acid, add an appropriate amount of water and stir for 10 minutes, stir and reflux at 300°C for 18 hours, and then add 15kg of ferric chloride , add water and stir into a paste, react for 2 hours, add water to cool, then continue to add water and wash at a speed of 1000 rpm in the centrifugal filter washing equipment for 30 minutes until the pH value is neutral, and centrifugally dehydrate until the moisture content is less than 30%. Dry at 105°C for 2 hours until the moisture is less than 0.2%, and the fixed carbon content of th...

Embodiment 2

[0058] 200 kg of natural graphite with a particle size of 75 μm and a carbon content of 90% was pulverized by a rotary high-speed pulverizer at a rotation speed of 5500 rpm for 20 minutes, and then spheroidized by a low-speed impact-type spherical pulverizer at a rotation speed of 2500 rpm for 60 minutes. After adjusting the particle size distribution, put 100kg of the above-mentioned graphite into the reaction kettle, add 35kg of mixed acid of sulfuric acid and nitric acid, add appropriate amount of water and stir for 15 minutes, stir and reflux at 360°C for 12 hours, then add 15kg of ferric chloride, add water and stir Make a paste, react for 2 hours, add water to cool, add water and wash in the centrifugal filter washing equipment at a speed of 300 rpm for 60 minutes until the pH value is neutral, and centrifugally dehydrate until the moisture content is less than 30%, in the oven at 100 ° C Dry for 2 hours until the moisture is less than 0.2%, and the fixed carbon content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| actual density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com