Patents

Literature

100results about How to "Increase charging current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

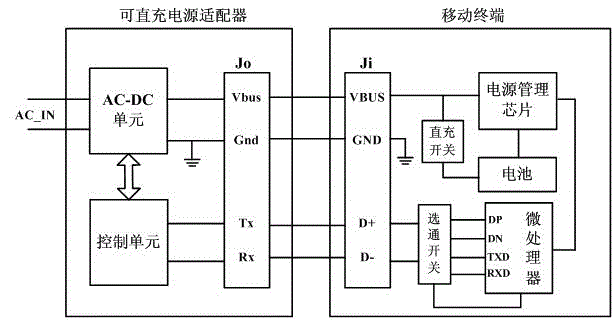

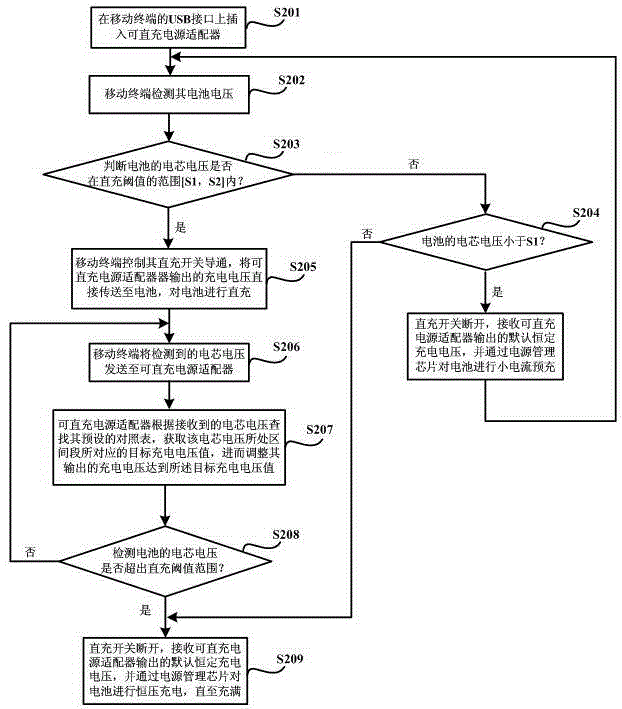

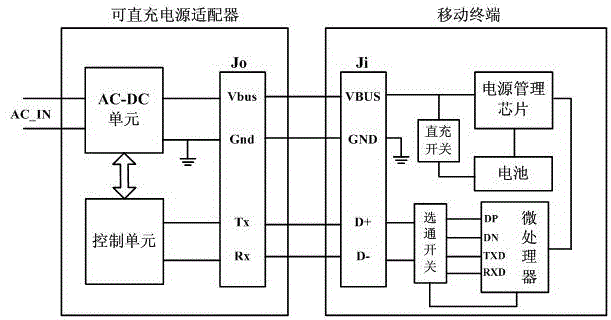

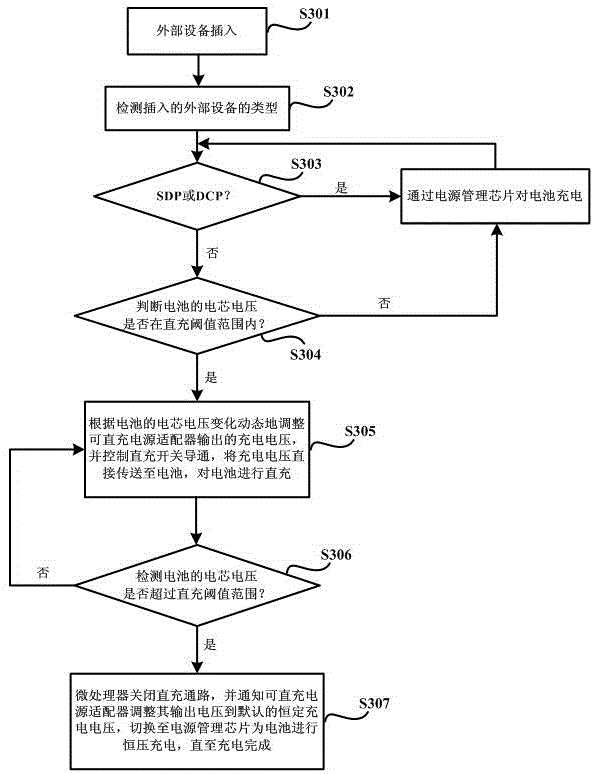

Fast-charging method, mobile terminal and power adapter capable of being charged directly

ActiveCN104967201AShorten the time required for a single chargeFast chargingSecondary cells charging/dischargingElectric powerCharge currentElectrical battery

The invention discloses a fast-charging method, a mobile terminal and a power adapter capable of being charged directly. The fast-charging method is provided based on the power adapter of which output voltage dynamic is adjustable. The voltage of the battery-core of a battery is divided into multiple sections, then a sectional-type constant-current charging way is adopted, the value of the charging voltage output through the power adapter is adjusted dynamically according to the located sections of the battery-core voltage of the battery inside the mobile terminal in the charging process, and the battery is charged directly through the charging voltage output through the power adapter, so that the charging current is improved greatly, thereby the charging speed of the battery is accelerated, the single-time charging time needed by the movable terminal is shortened, the influence of the situation that the mobile terminal needs to be charged frequently for a long time on daily use of a user is lowered, and the customer-using satisfaction degree in promoted to a large extent.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

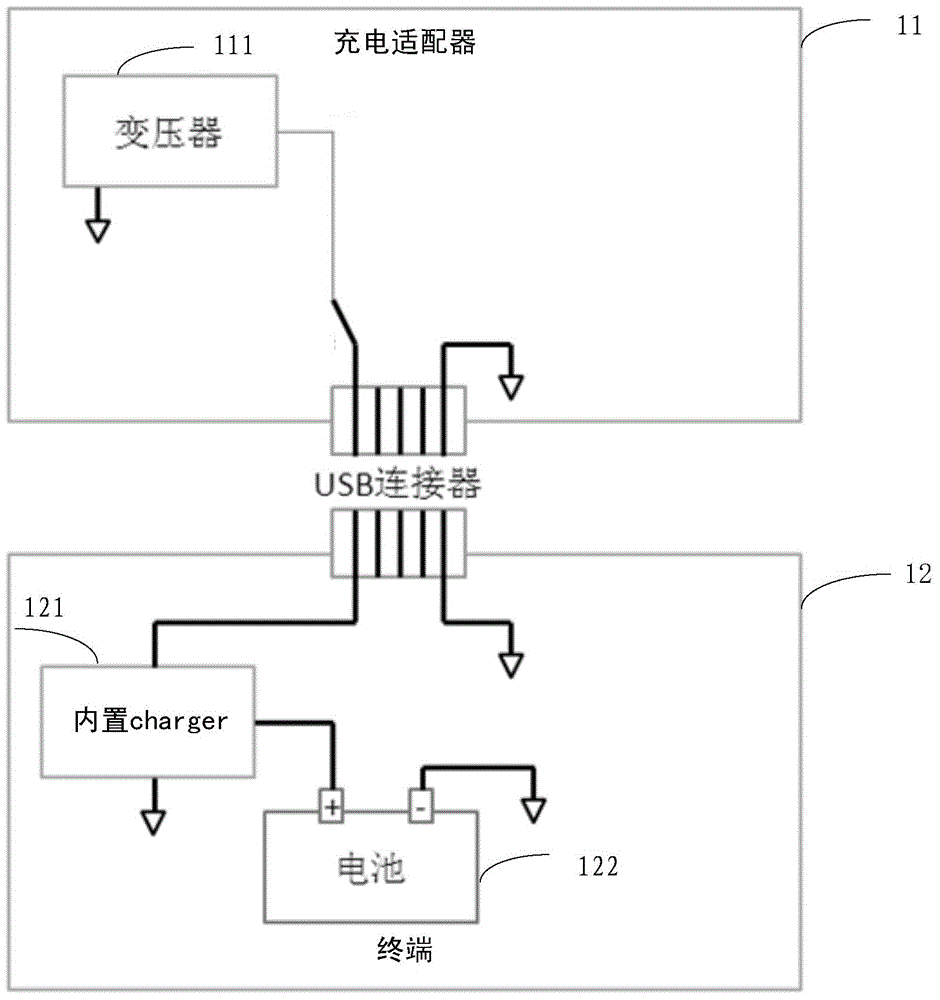

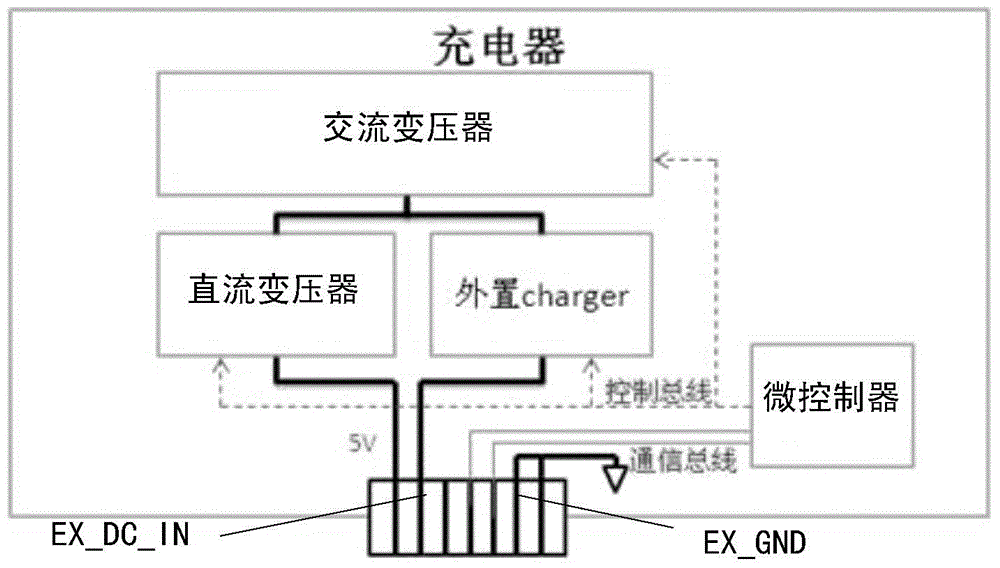

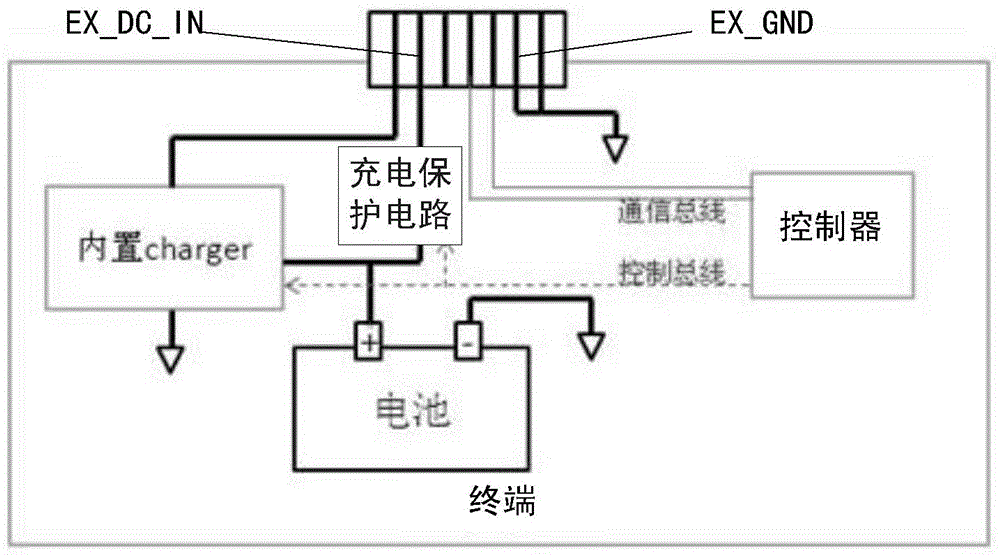

Charging adapter, terminal and charging control method

ActiveCN104065147AIncrease charging currentImprove charging efficiencyBatteries circuit arrangementsSecondary cells charging/dischargingState of artCharge current

The invention discloses a charging adapter, a terminal and a charging control method, and aims to solve the problem that the charging current is difficult to increase in the prior art. The charging adapter comprises an alternating-current transformer, a direct-current transformer, an external charging chip and a micro controller. The output end of the alternating-current transformer is connected with the direct-current transformer and the external charging chip. The micro controller is used for causing the alternating-current transformer to provide direct-current output and causing the direct-current transformer to carry out direct current transformation and output after the charging adapter and the terminal are effectively connected, and used for causing the external charging chip to charge the terminal after handshake connection between the charging adapter and the terminal is established. By adopting the charging adapter provided by the embodiment of the invention, the charging current can be increased, and the charging efficiency can be improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

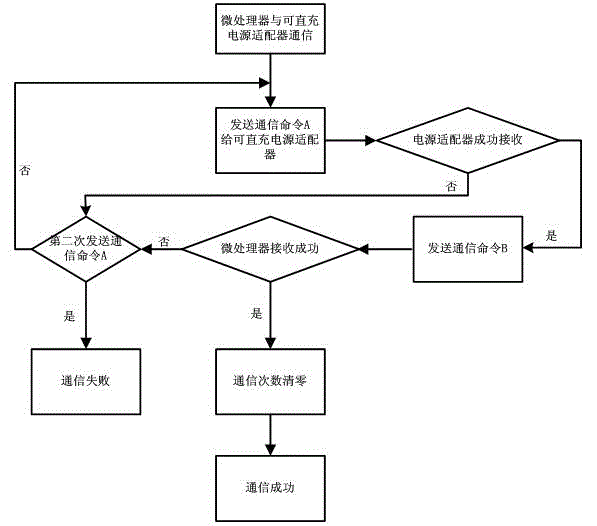

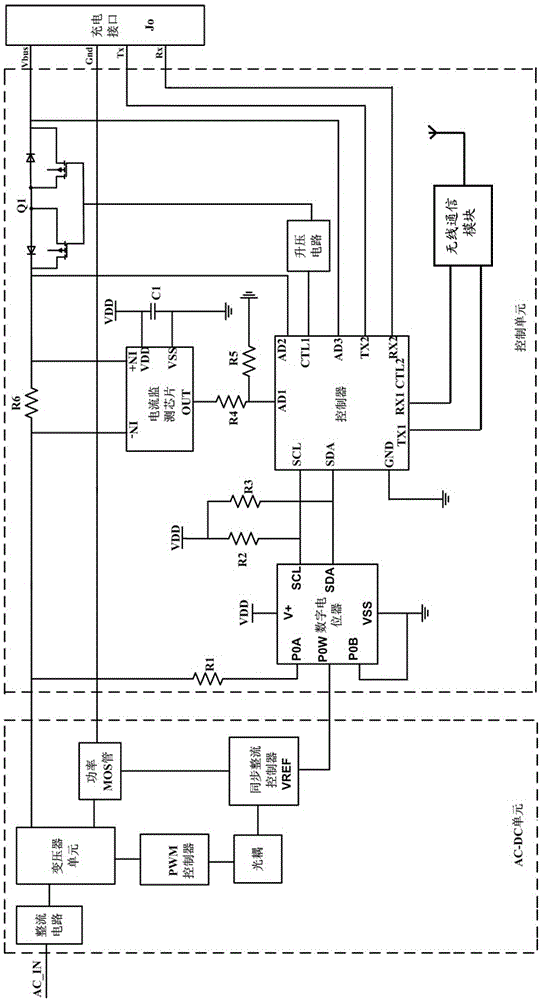

Power adapter capable of direct charging

ActiveCN105098945AShorten the timeFast chargingElectric powerExchanging data chargerCharge currentEngineering

The invention discloses a power adapter capable of direct charging. The power adapter adapts an UART communication mode to regularly communicate with a mobile terminal as a charging target, so as to obtain the voltage variation of the battery in the mobile terminal; the volt value of the output charging voltage is dynamically adjusted according to the variation of the battery voltage, the charging voltage directly charges a built-in battery of the mobile terminal, so as to realize the great increase of the charging current, accelerate the charging speed of the battery, and shorten the one-time charging time of the mobile terminal, then the inconvenience on user daily use caused by the long charging time of mobile terminal can be reduced, and the user satisfaction is greatly improved.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

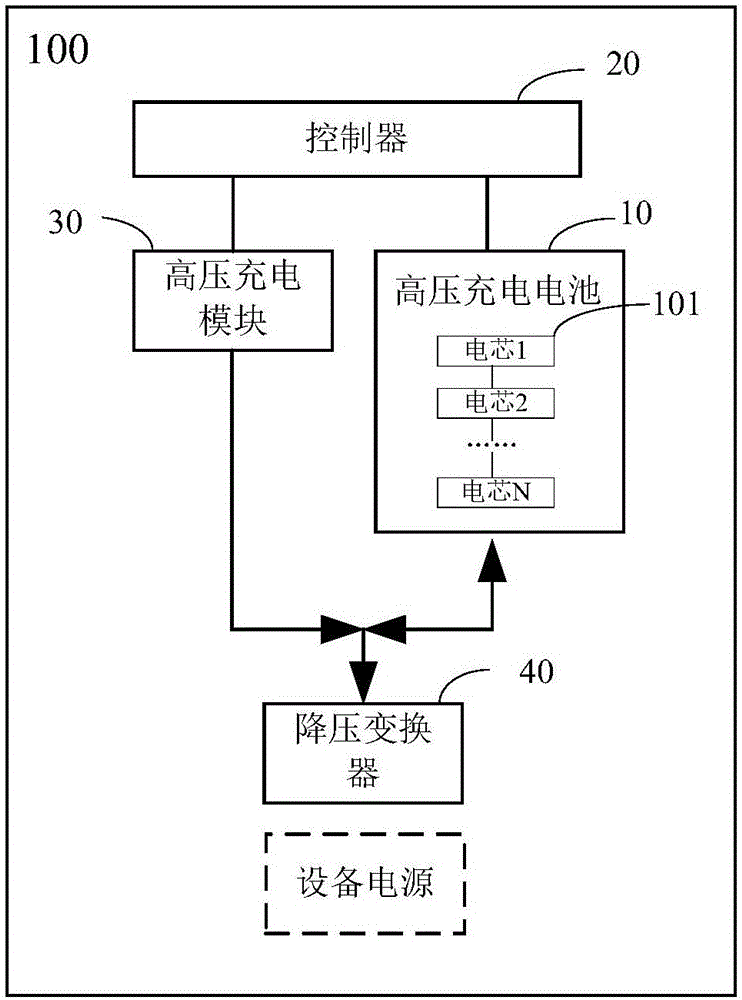

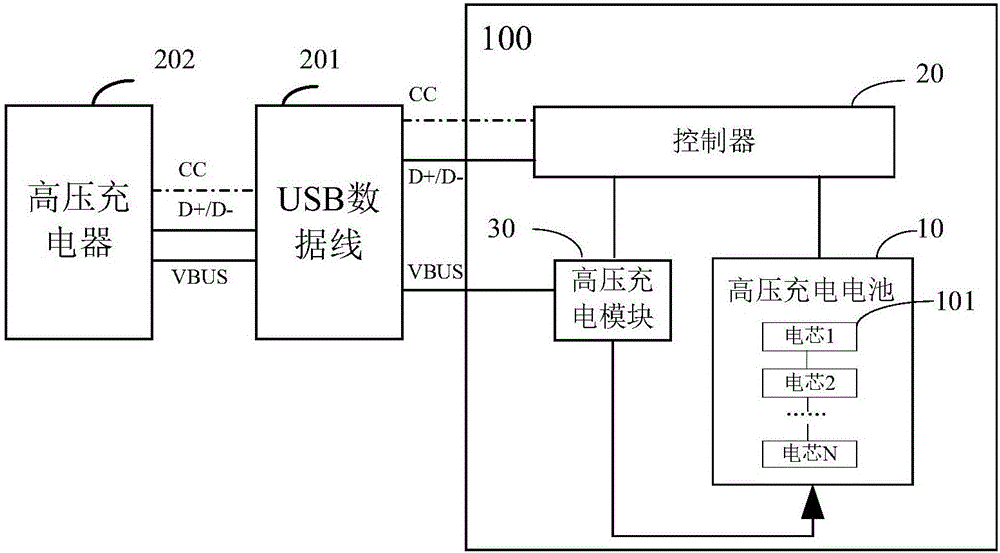

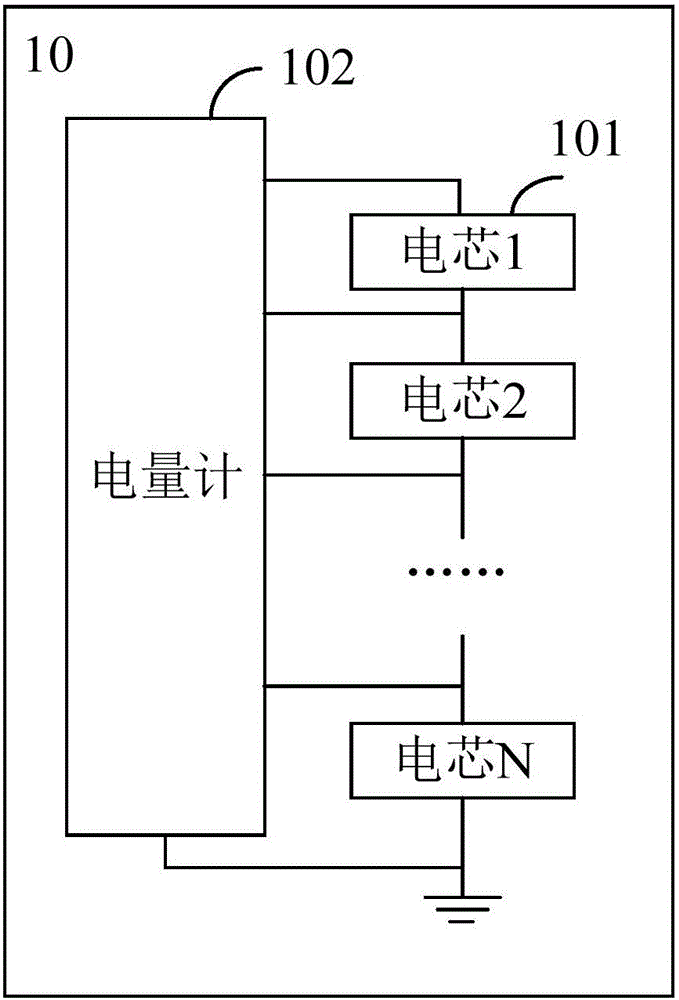

High-voltage charging system, high-voltage charging battery and terminal device

InactiveCN106169798AReduce lossIncrease charging currentElectric powerArrangements for several simultaneous batteriesCharge currentBuck converter

The invention relates to a high-voltage charging system, a high-voltage charging battery and a terminal device. The high-voltage charging system comprises the high-voltage charging battery, a controller, a high-voltage charging module and a buck converter, wherein the high-voltage charging battery comprises a plurality of battery cells connected in series; the controller is used for regulating an output voltage of the high-voltage charging module according to a voltage of the high-voltage charging battery; the high-voltage charging module is used for outputting a charging current of a predetermined magnitude to the high-voltage charging battery for charging the high-voltage charging battery; and the buck converter is used for converting the output voltage of the high-voltage charging module or the high-voltage charging battery into a device power supply. According to the technical scheme, a charging voltage can be increased and a charging current can be reduced, so that the energy loss on a charging path is reduced and the heat value is reduced.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

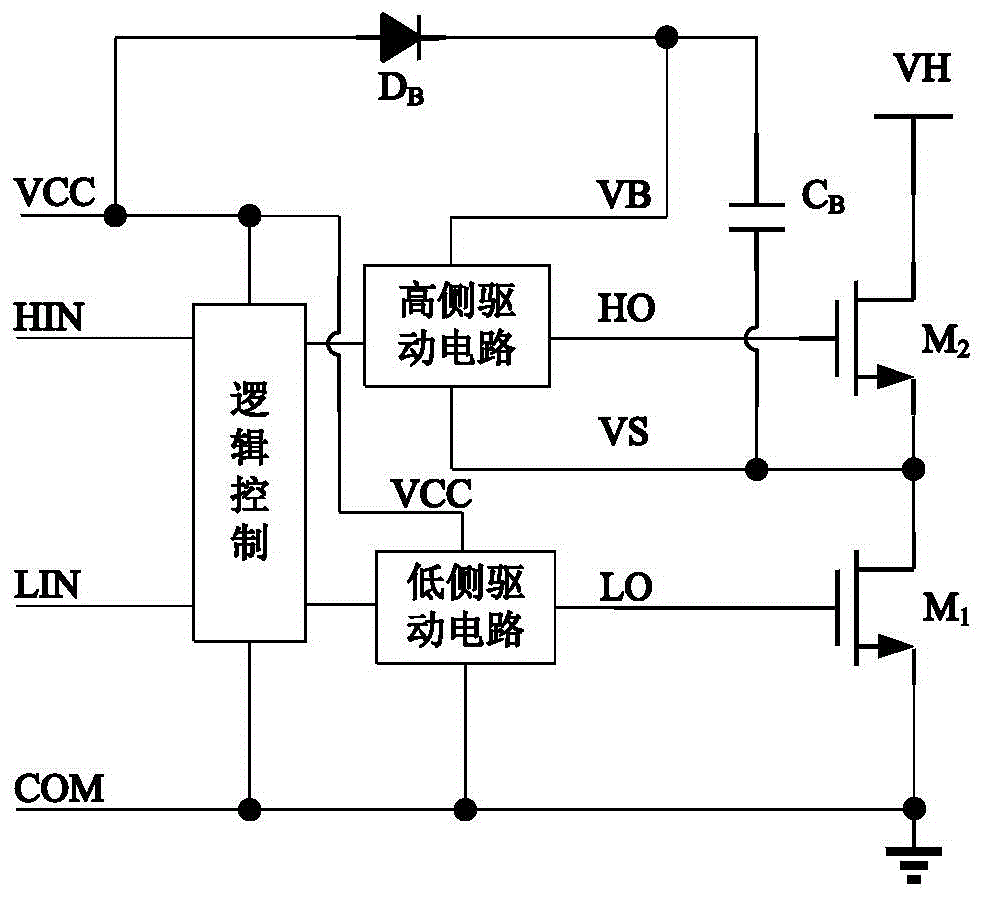

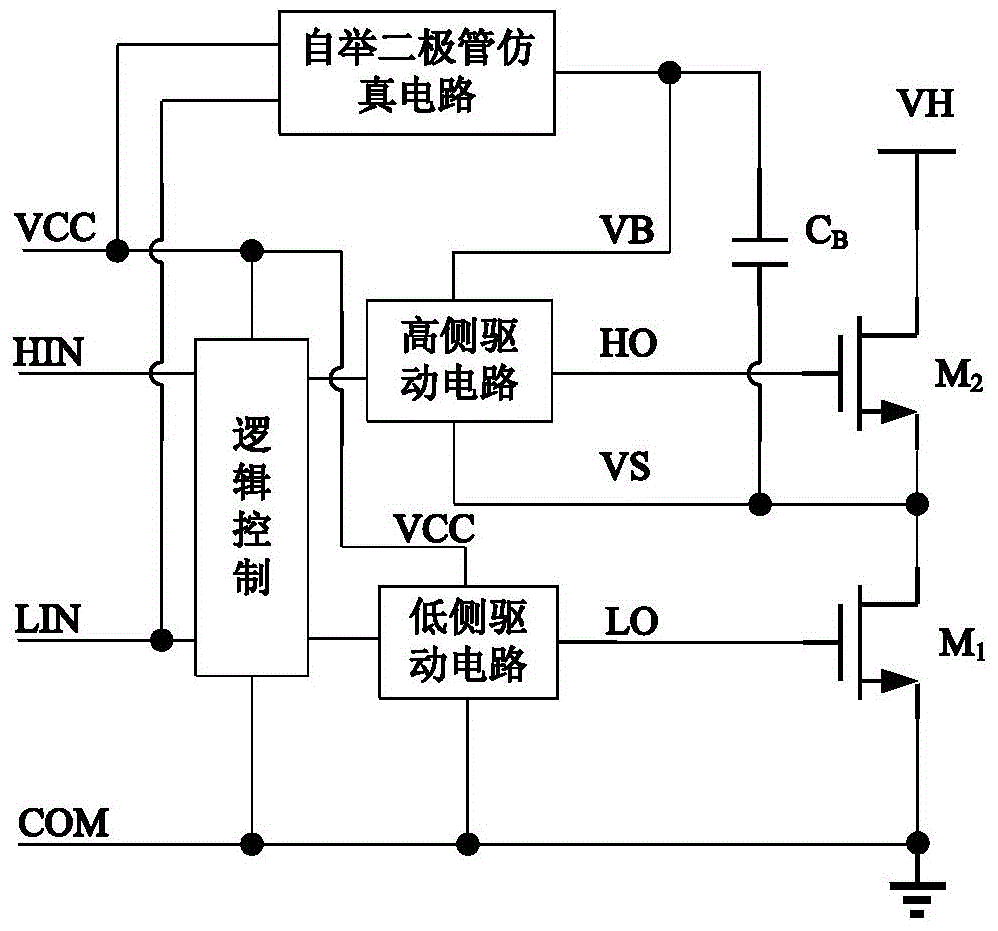

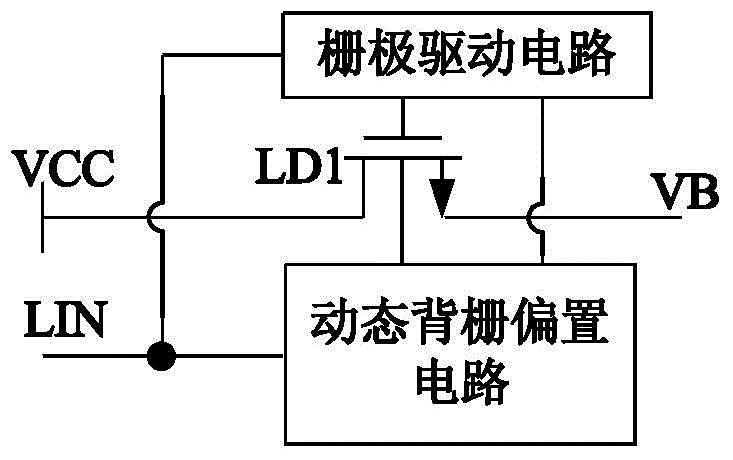

Bootstrapping diode artificial circuit in half-bridge driving circuit

ActiveCN104022776ARaise the gate voltageIncrease charging currentLogic circuits using semiconductor devicesCapacitanceEngineering

The invention provides a bootstrapping diode artificial circuit in a half-bridge driving circuit. An electrical level displacement and a simple charge pump are added into a grid driving circuit structure in an existing bootstrapping diode artificial circuit; when a grid driving input signal is a low electrical level, grid voltage output to an N-channel LDMOS (Lateral Diffusion Metal Oxide Semiconductor) transistor LD1 by a grid driving circuit is a low electrical level; the N-channel LDMOS transistor LD1 is turned off. When the grid driving input signal is a high electrical level, the grid voltage output to the N-channel LDMOS transistor LD1 by the grid driving circuit is a high electrical level so that the grid voltage of the N-channel LDMOS transistor LD1 is improved, the conduction resistance of the LD1 is reduced and the charging current to a bootstrapping capacitor is improved.

Owner:SOUTHEAST UNIV

Method for container formation of lead-acid storage battery

ActiveCN102983366AImprove cycle lifeHigh initial capacityFinal product manufactureSecondary cells charging/dischargingWater bathsPower flow

The invention discloses a method for container formation of a lead-acid storage battery. The method comprises the following steps of: placing a lead-acid storage battery filled with electrolyte into a circulating water bath, cooling to 40 DEG C below, conducting charging and discharging, wherein the specific charging and discharging processes include eight charging processes and two discharging processes. According to the method, by adding a second-stage and a fifth-stage charging currents, the charging efficiency is improved, the container formation time of the battery is shortened, and the initial-stage capacity and recycling life of the battery can also be increased and prolonged, so that the method has great significances for the production of the storage battery.

Owner:ZHEJIANG TIANNENG POWER ENERGY

Processing for manufacturing metallized polypropylene film capacitor

InactiveCN101604575AReduce lossIncrease charging currentThin/thick film capacitorStacked capacitorsThermal sprayingProduct testing

The invention discloses a process for manufacturing a metallized polypropylene film capacitor, which comprises the steps of slug manufacturing, slug shaping, slug membrane enveloping and metal spraying, energizing, soaking and internal sealing, slug assembling and finished product testing, wherein in the step of the slug membrane enveloping and metal spraying, a dust removing plant is used to absorb floating dust metal particles so that metal spraying particles effectively contact with the end face of a staggered edge of the capacitor, the contact performance is reliable, the resistance is small, and particularly at a high frequency, the metal loss is far smaller and the charging current and the withstand voltage of the capacitor are improved; and in the step of the soaking and internal sealing, the vacuum degree is required to be reduced to be below -0.1 MPa to perform the soaking, the reliability of edge arcing is improved and the withstand voltage is also improved. The metallized polypropylene film capacitor produced by the manufacturing process has the advantages of small volume, high-voltage resistance and good dielectric property, the compression strength is improved to two times, the loss is 10 KHZ, the dielectric loss angle tangent is 0.001, and the temperature shock resistance is between 40 and 100 DEG C.

Owner:ZHEJIANG QIXING CAPACITOR

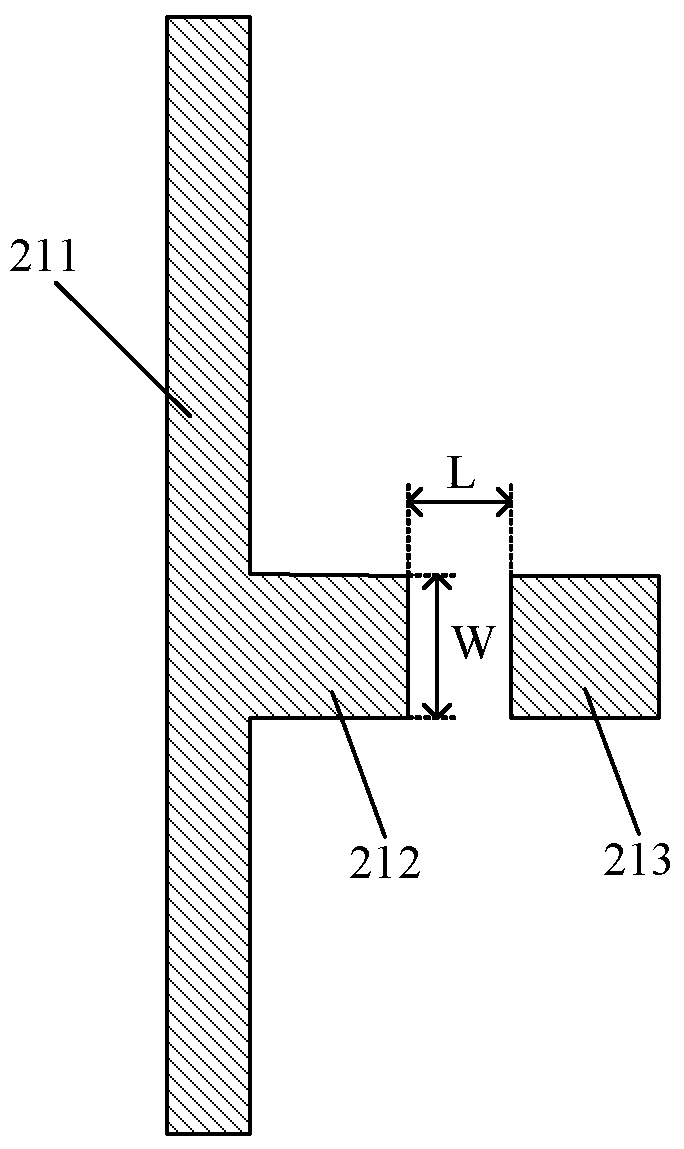

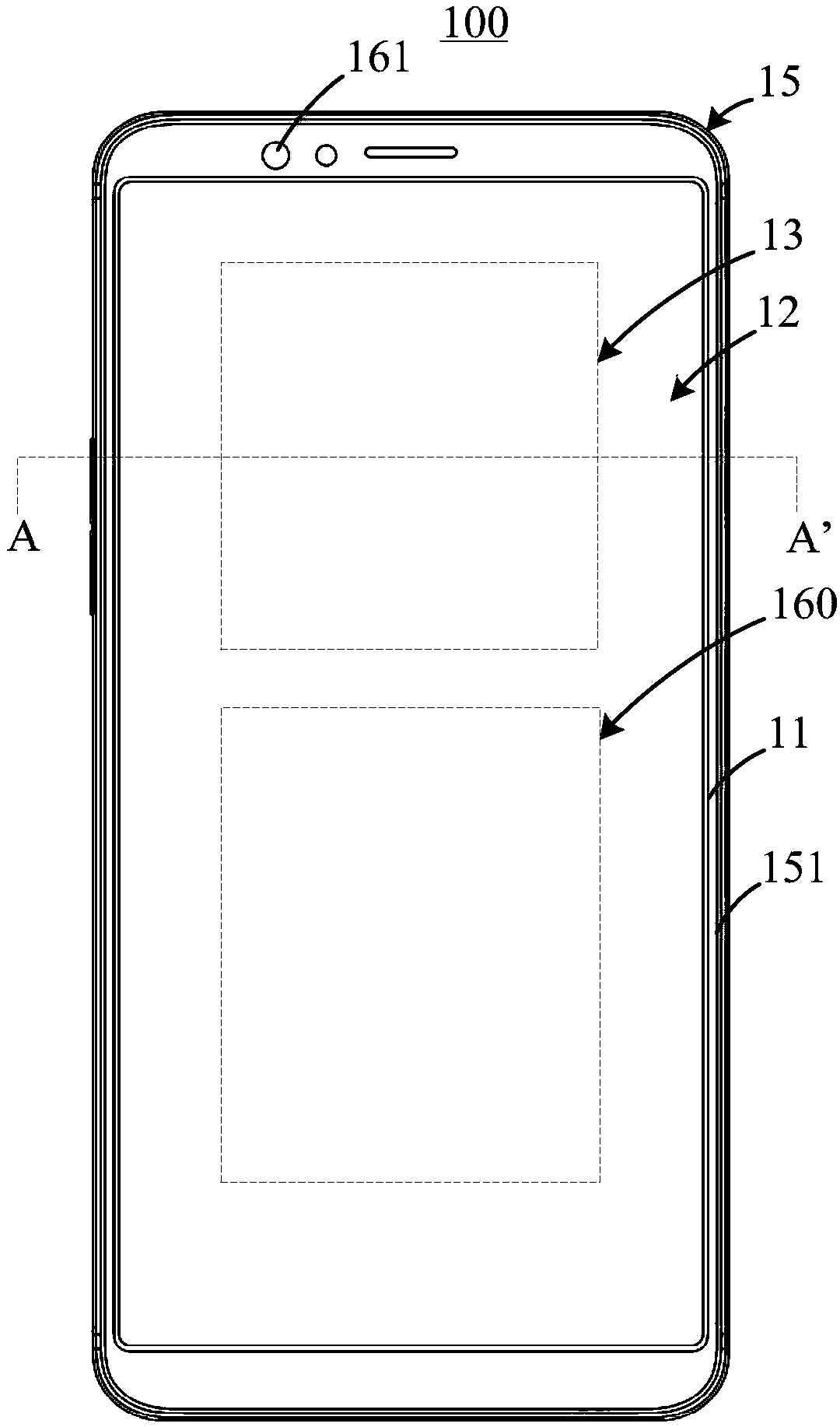

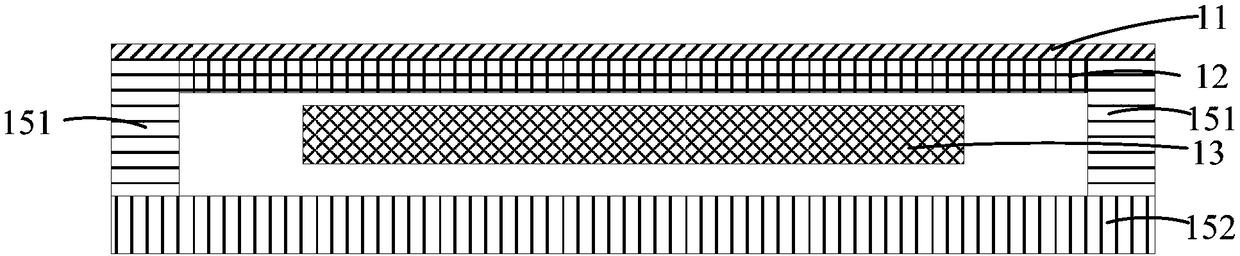

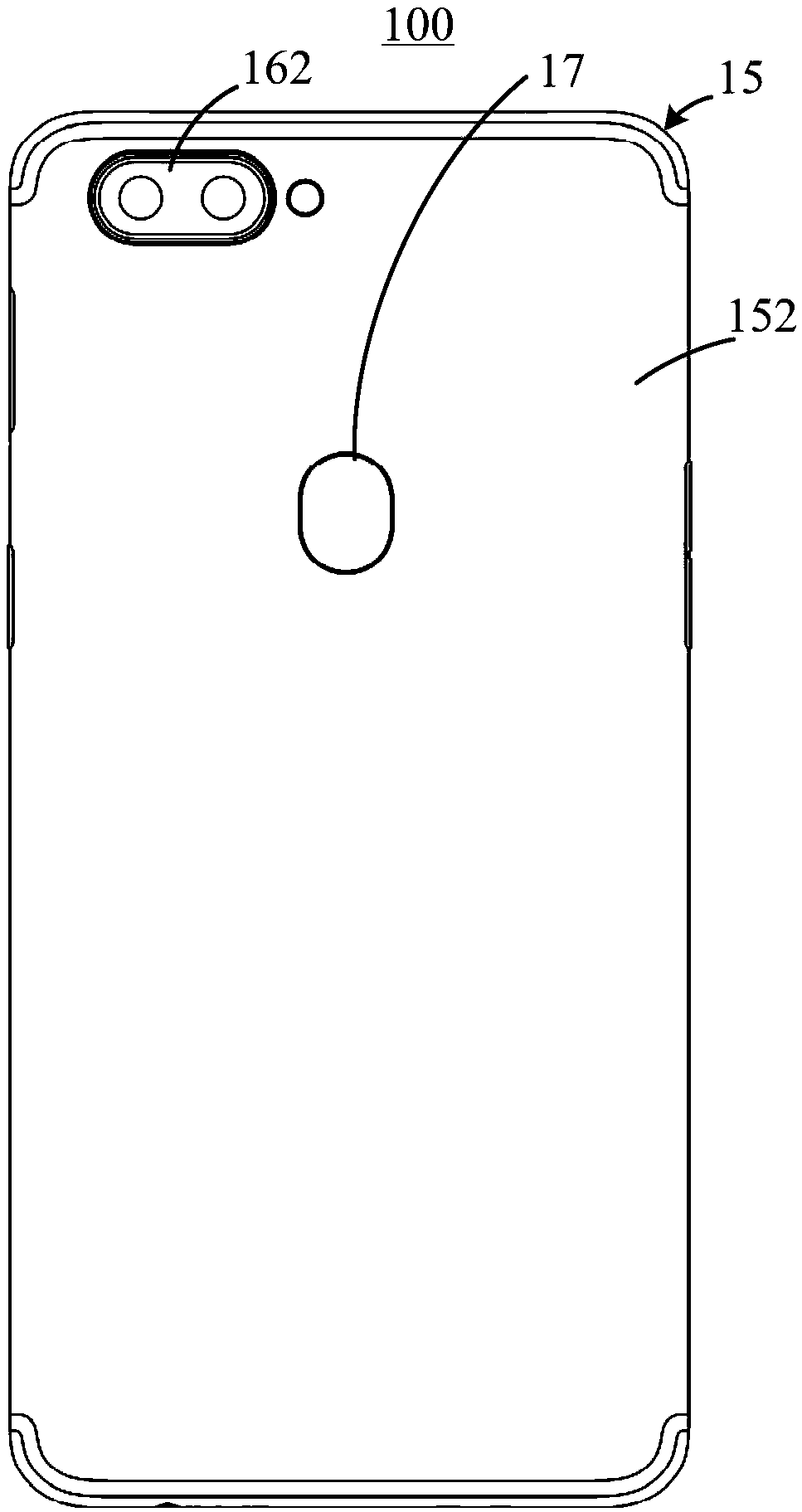

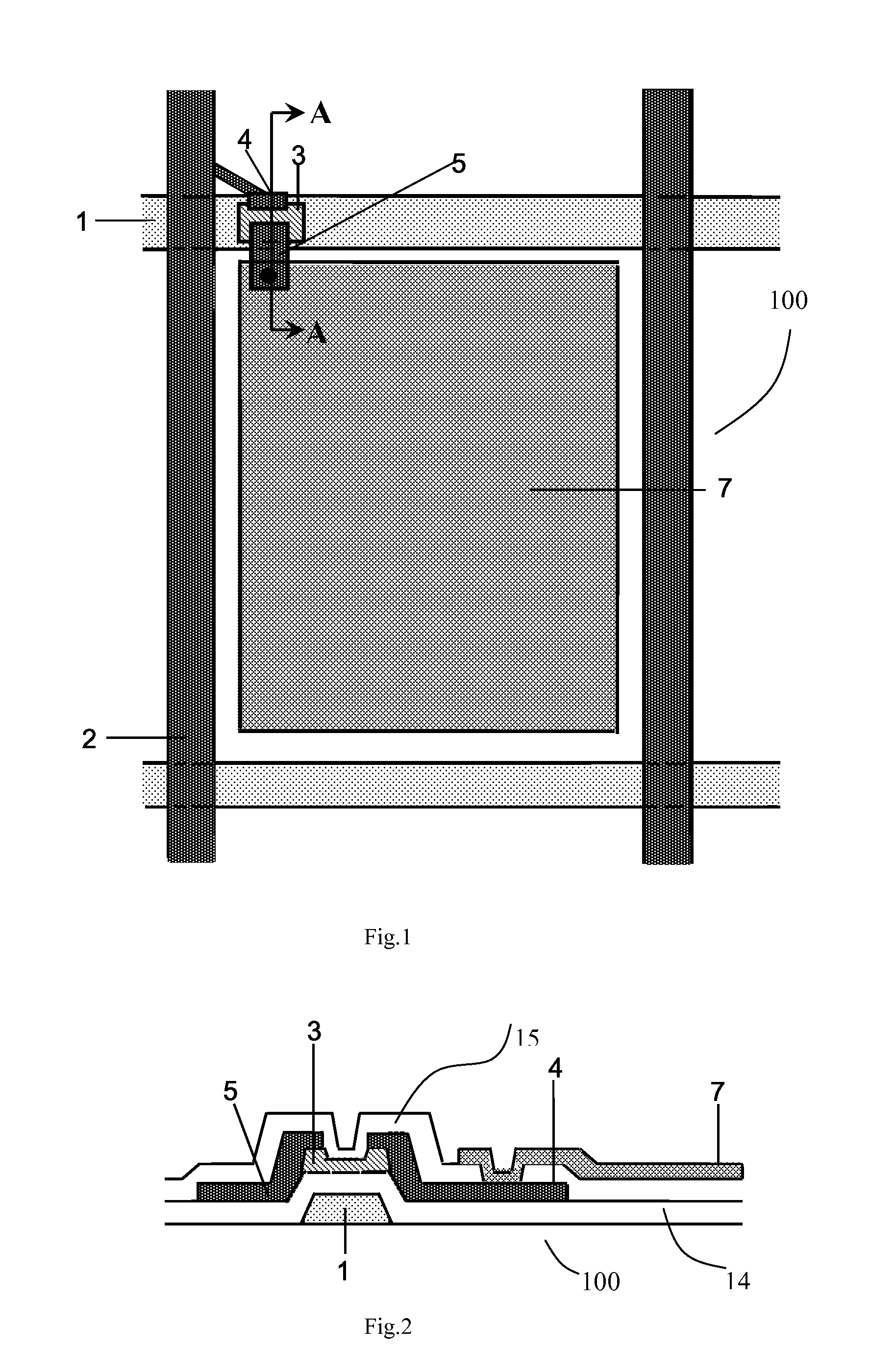

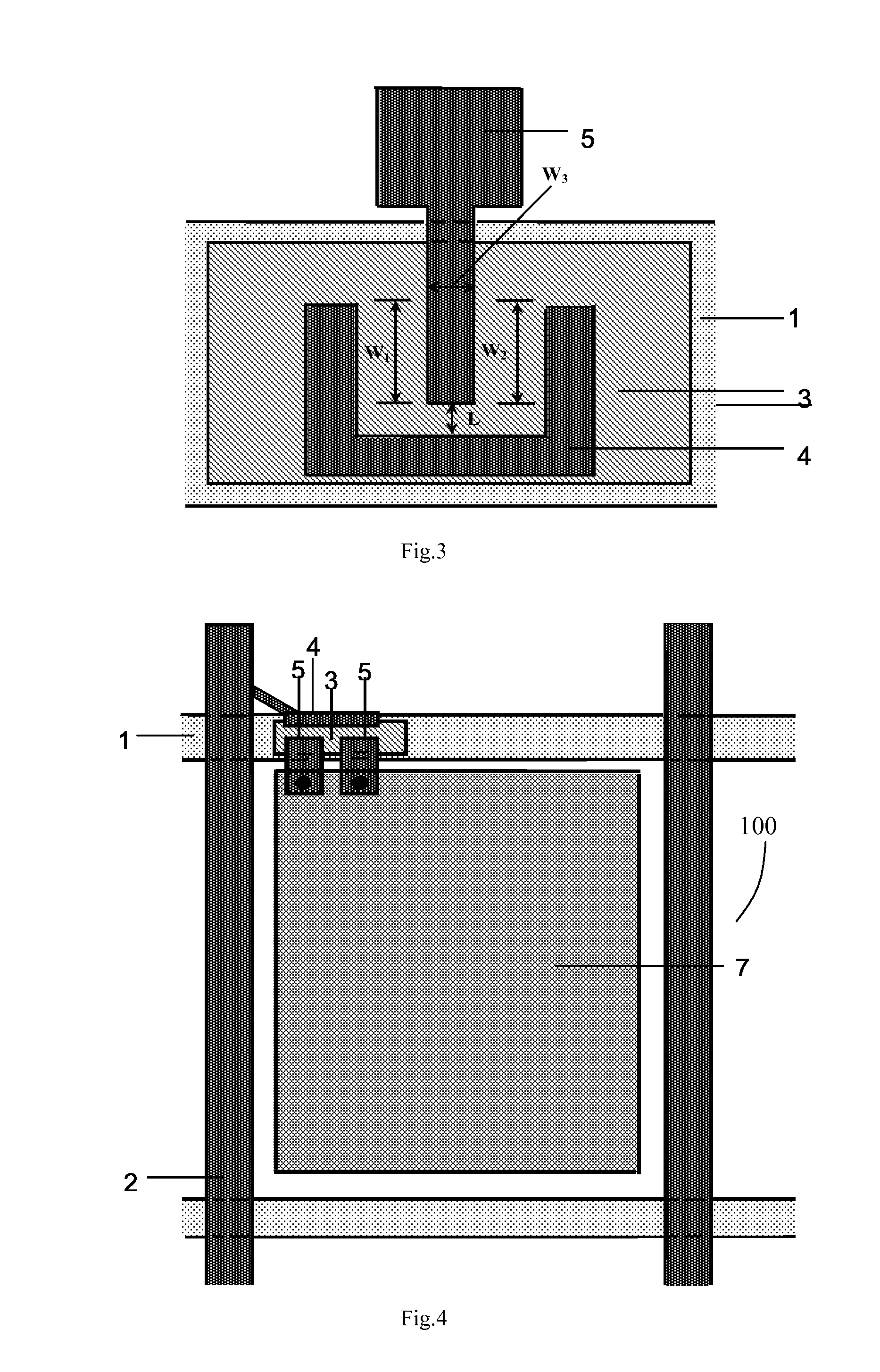

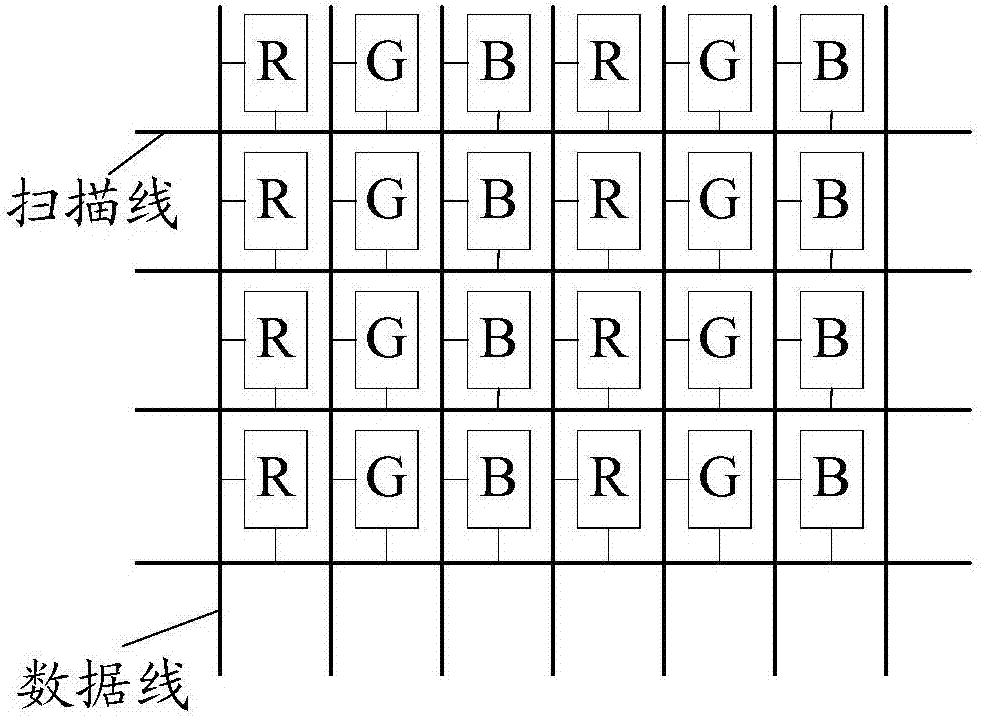

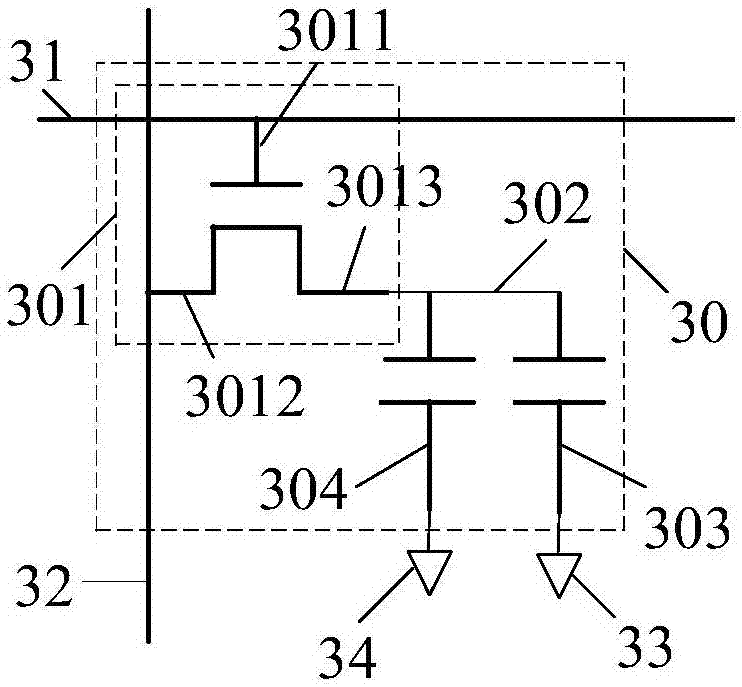

Array substrate, manufacturing method thereof and display device

InactiveCN103762218AReduce areaIncrease charging currentTransistorSolid-state devicesPower flowCharge current

The invention discloses an array substrate, a manufacturing method of the array substrate and a display device. The array substrate comprises a supporting base substrate, a grid line, a data line, pixel electrodes and a thin film transistor, wherein the grid line, the data line, the pixel electrodes and the thin film transistor are formed on the supporting base substrate. The thin film transistor comprises a grid electrode, an active layer and a source-drain electrode graph, the source-drain electrode graph is connected with the active layer, and the pixel electrodes are connected with the active layer. A source electrode and a drain electrode are arranged to be the source-drain electrode graph, the area of the thin film transistor is reduced, and therefore the aperture opening ratio of pixels is improved. The source electrode and the drain electrode are arranged to be one source-drain electrode graph, the width-to-length ratio W / L of a channel of the thin film transistor is increased, the charging current of the thin film transistor is improved, and therefore the charging capacity of the thin film transistor is improved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

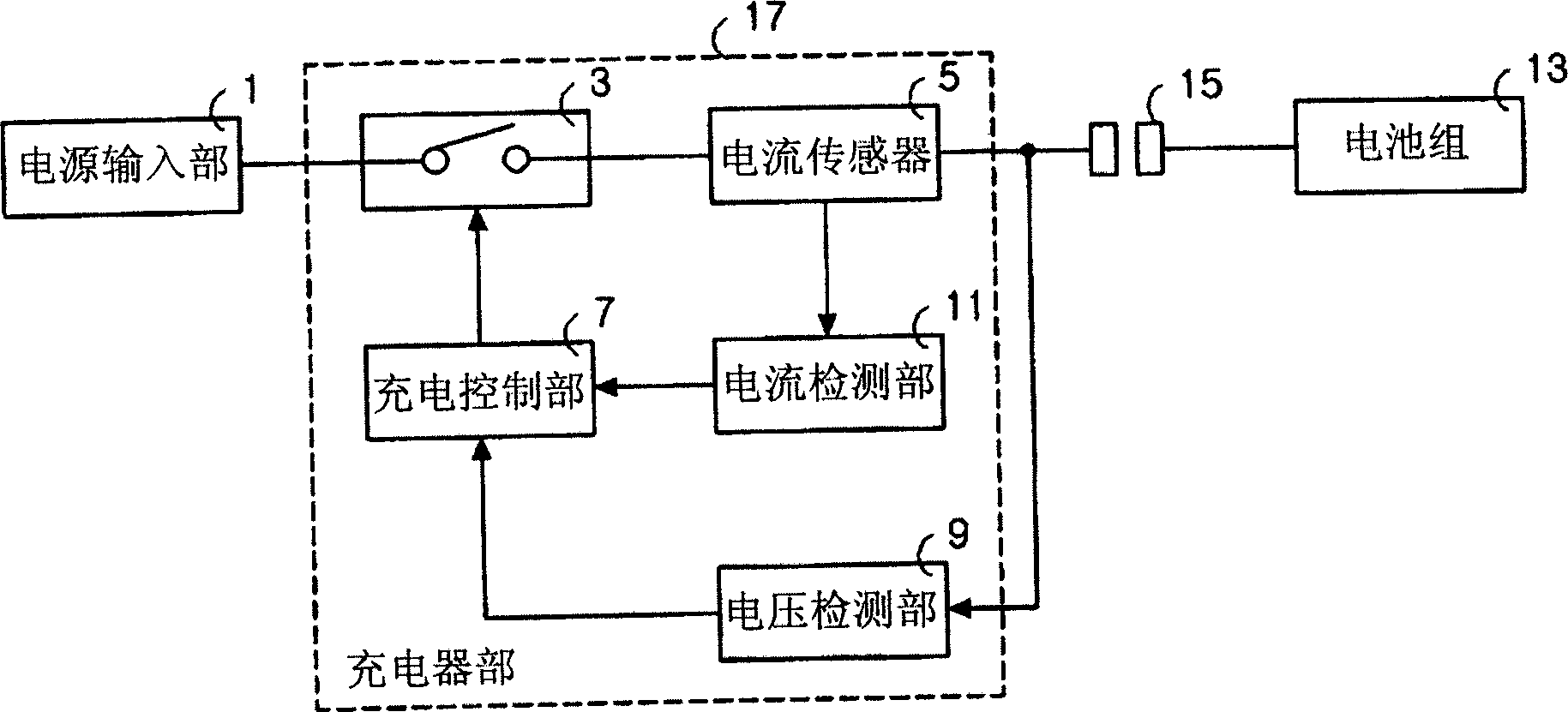

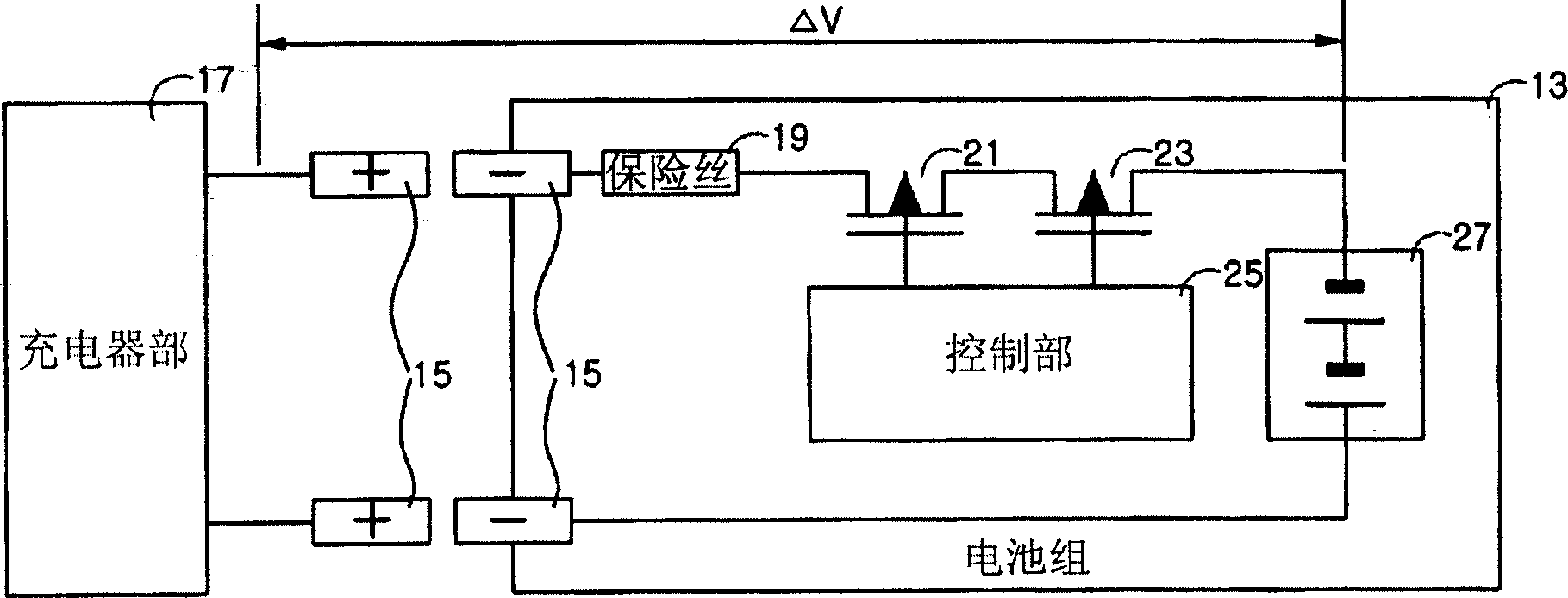

Controlling a charging operation of a battery

InactiveCN1897398AImprove charging efficiencyCharge capacity adjustmentBatteries circuit arrangementsSecondary cells charging/dischargingCharge voltageCharging station

The invention relates to a controlling device and a controlling method for charging operation of a battery, that is to say, it is a device and method to optimize charging stations of the batteryby adjusting charging capacity of the battery. The method includes reading an actual full charge capacity of the battery and a design capacity of the battery. The actual full charge capacity of the battery is compared with the design capacity of the battery. A charge voltage and a charge current are adjusted if the actual full charge capacity is less than the design capacity. The charge voltage and the charge current in adjusting step is used for controlling the charging operation of the battery. This invention determines the charging station, if the nonce full charge capacity is less than the design capacity, the charging operation of the battery is controlled by the adjusted charge voltage and charge current which are adjusted by decreasing charge current and increasing charge voltage. This invention can properly adjusts the full charge capacity of the battery and increases the charging efficiency.

Owner:LEJIN ELECTRONICS KUNSHAN COMPUTER CO LTD

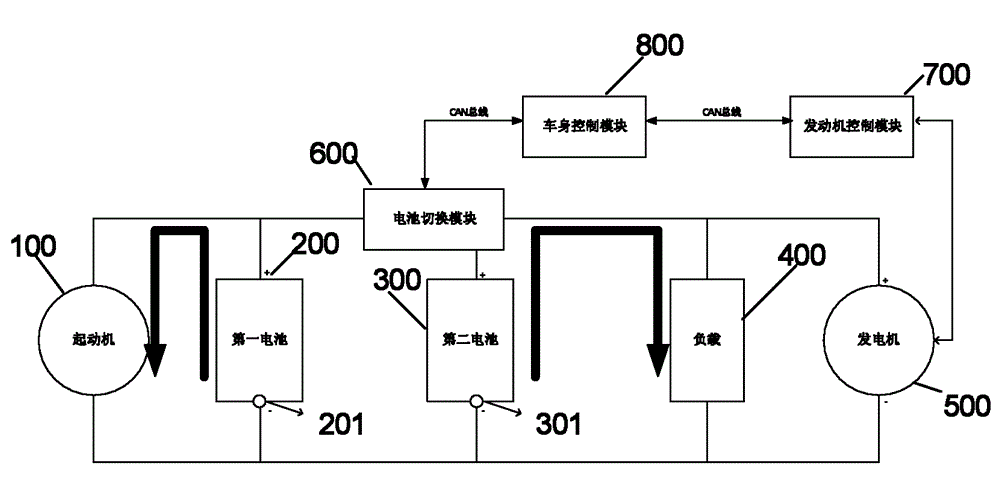

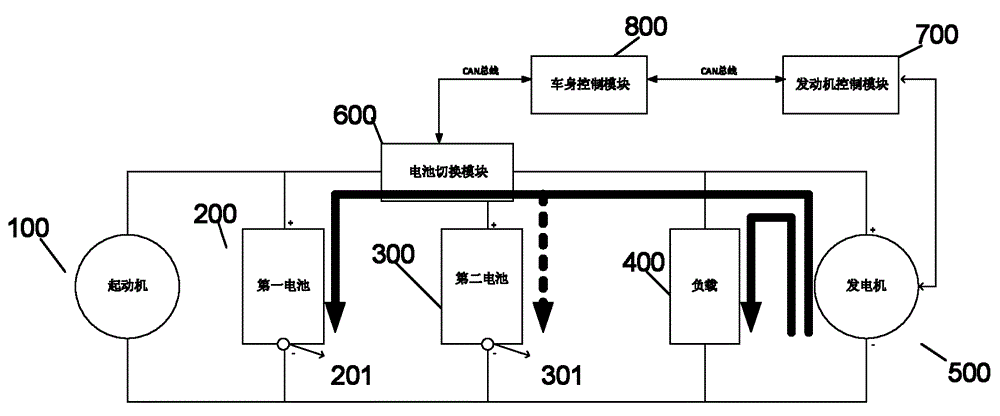

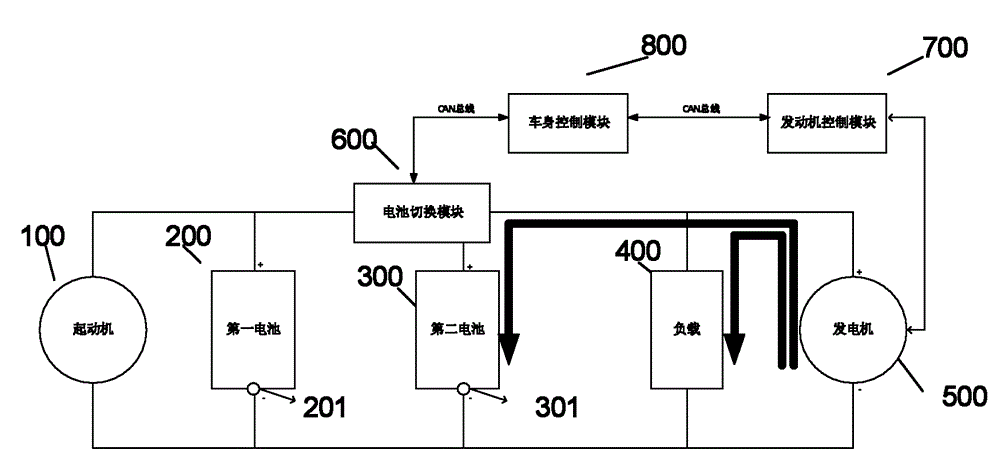

Double battery management system of engine automatic start and stop vehicle

ActiveCN104999920AReduce control complexityContribution to lower fuel consumptionVehicular energy storageElectric propulsionElectrical batteryComputer module

The present invention relates to a double battery management system of an engine automatic start and stop vehicle. The double battery management system is provided with a starter; a first battery only used for power supply of the starter; a second battery used for power supply of loads of the whole vehicle; a generator used for power supply of the first battery and / or the second battery and the whole vehicle; a first battery sensor used for acquiring electric quantity information and charging / discharging information of the first battery; a second battery sensor used for acquiring electric quantity information and charging / discharging information of the second battery; a battery switching module used for switching connection / disconnection of the first battery, the second battery and a whole vehicle network; an engine control module used for controlling an engine; and a vehicle body control module used for controlling the battery switching module and performing information interaction with the engine control module, the first battery sensor and the second battery sensor.

Owner:SAIC GENERAL MOTORS +1

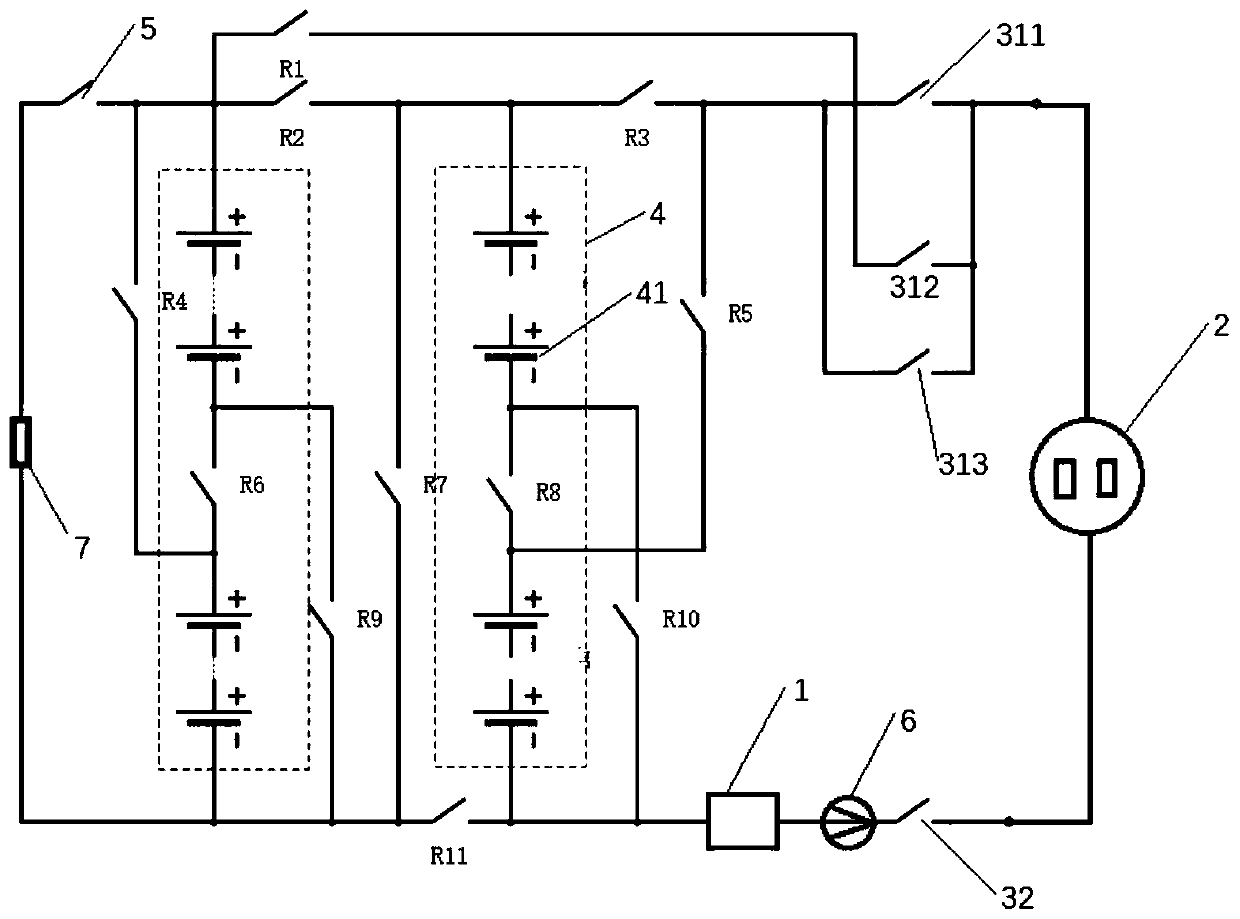

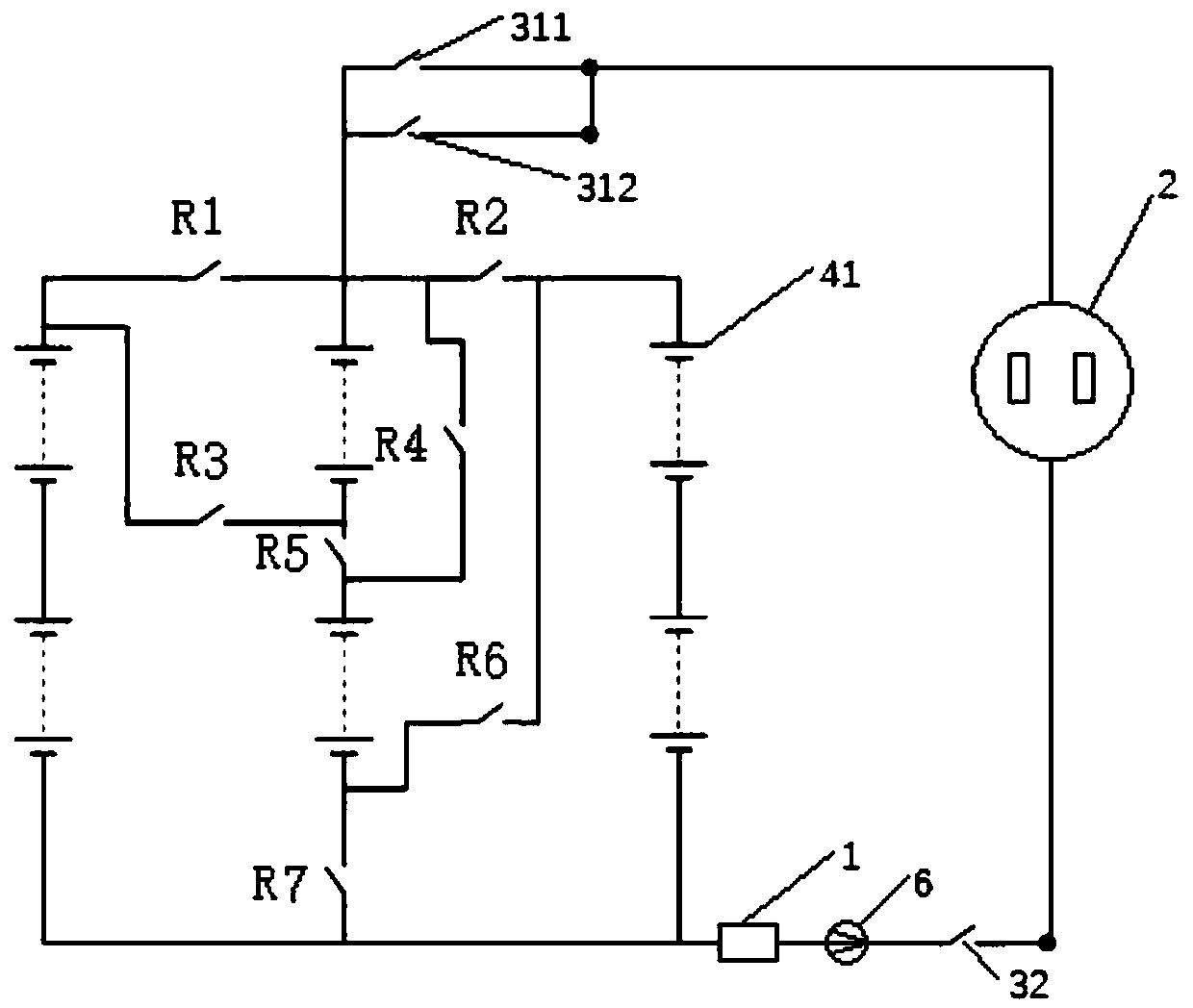

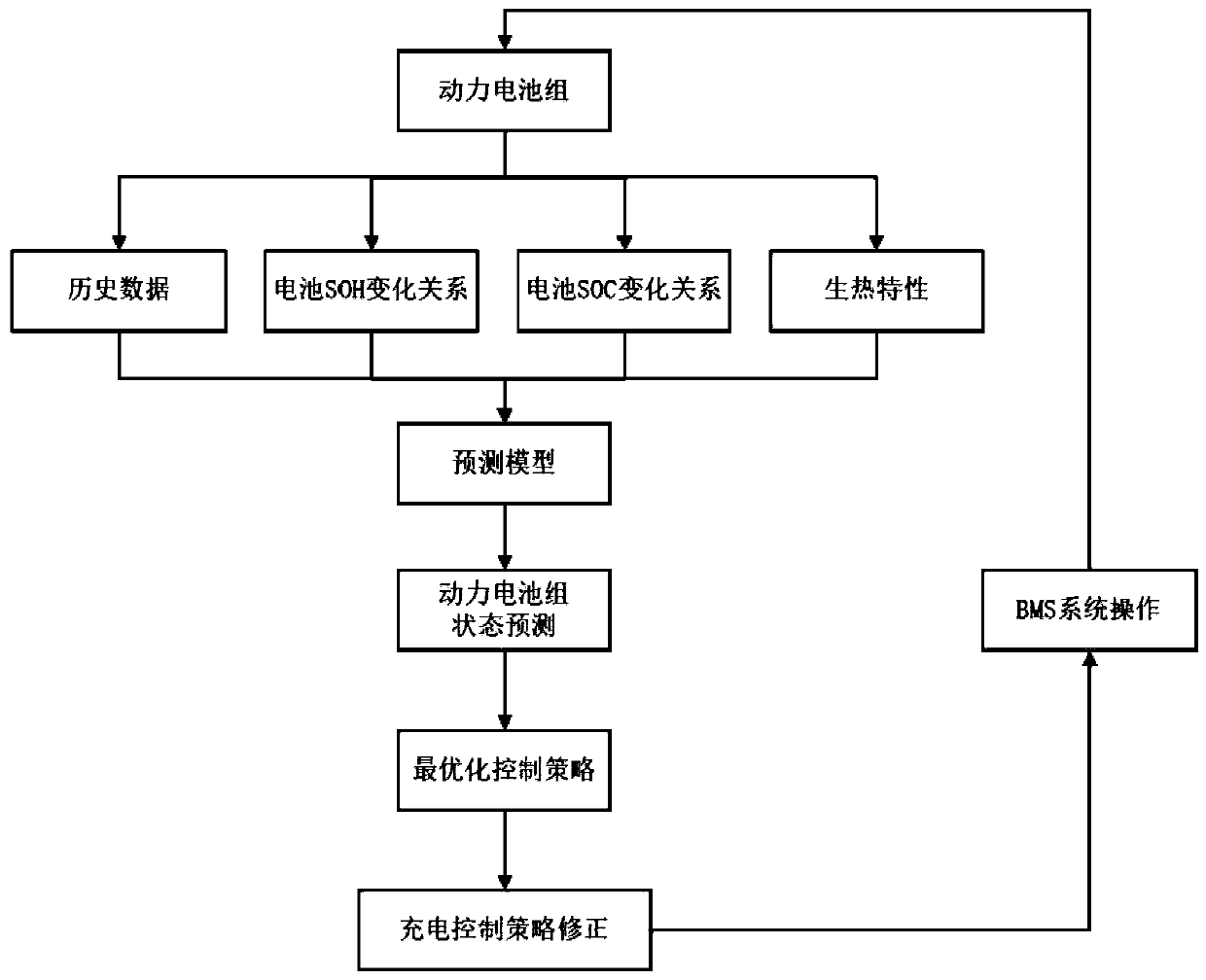

High-adaptive charging system and method for electric vehicle

ActiveCN110429671AImprove charging experienceIncrease charging voltageParallel/serial switchingCells structural combinationLow voltageElectrical battery

The invention relates to a high-adaptive charging system and method for an electric vehicle. The system comprises a power battery pack, a battery management system, a charging interface, a charging positive relay, a charging negative relay and a structure conversion relay group, wherein the charging positive relay comprises a positive relay in a common charging mode, a positive relay in a high-voltage charging mode, and a positive relay in a low-voltage charging mode. The structure conversion relay group controls the series-parallel connection structure of the battery pack, adjusts the charging voltage of the electric vehicle, and adjusts the charging voltage of the battery pack under the allowable charging current of a charger in order to adapt to a connected charging pile. For a high-voltage high-power charger, the system increases the charging voltage of the battery pack and the charging power of the battery pack, shortens the charging time, and improves the adaptability of the electric vehicle to long-distance driving. For a low-voltage charger, the system reducing the charging voltage of the battery pack, makes the battery pack compatible with the low-voltage charger, and reduces the dependence of the electric vehicle on general charging infrastructure.

Owner:BEIHANG UNIV

Charging circuit, electronic device, charging management method and storage medium

PendingCN109120029APrevent backfeedingIncrease charging currentSafety/protection battery circuitsSecondary cells charging/dischargingCharge currentElectrical battery

The embodiment of the invention provides a charging circuit, an electronic device, a charging management method and a storage medium. The charging circuit comprises a wired charging module and a wireless charging module, the wired charging module comprises a first input end, a first output end and a first unilateral conduction unit, the wired charging module is configured to charge a battery connected with the first output end by employing a wired charger connected with the first input end, the first unilateral conduction unit prevents signals from being transmitted to the first input end fromthe first output end; the wireless charging module comprises a second input end, a second output end and a second unilateral conduction unit, the wireless charging module is configured to charge a battery connected with the second output end by employing a wireless charger being in non-contact connection with the second input end, and the second unilateral conduction unit is configured to preventthe signals from being transmitted to the second input end from the second output end. The wired charging module and the wireless charging module can charge the batteries at the same time so as to improve the charging current and shorten the charging time.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

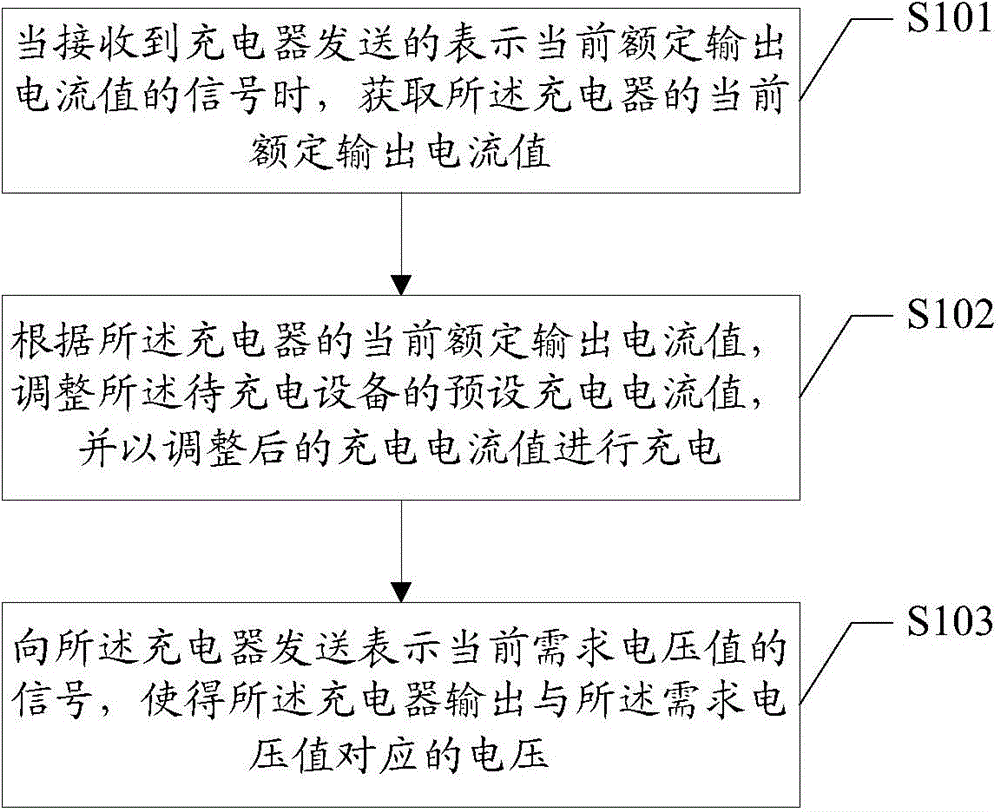

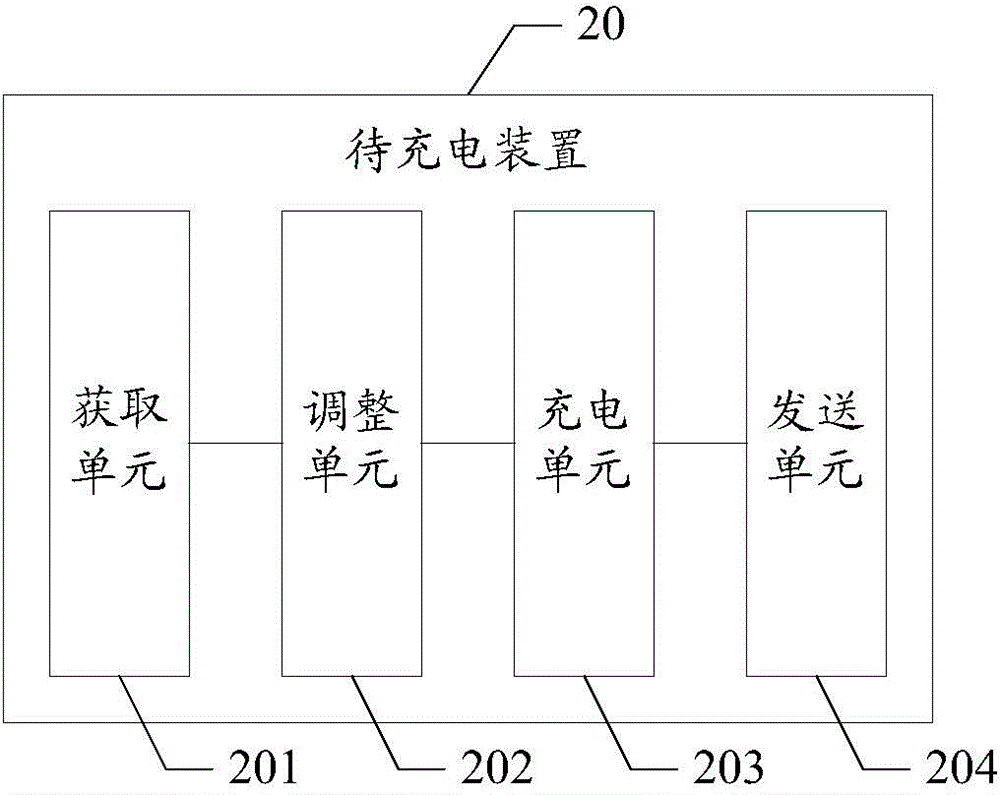

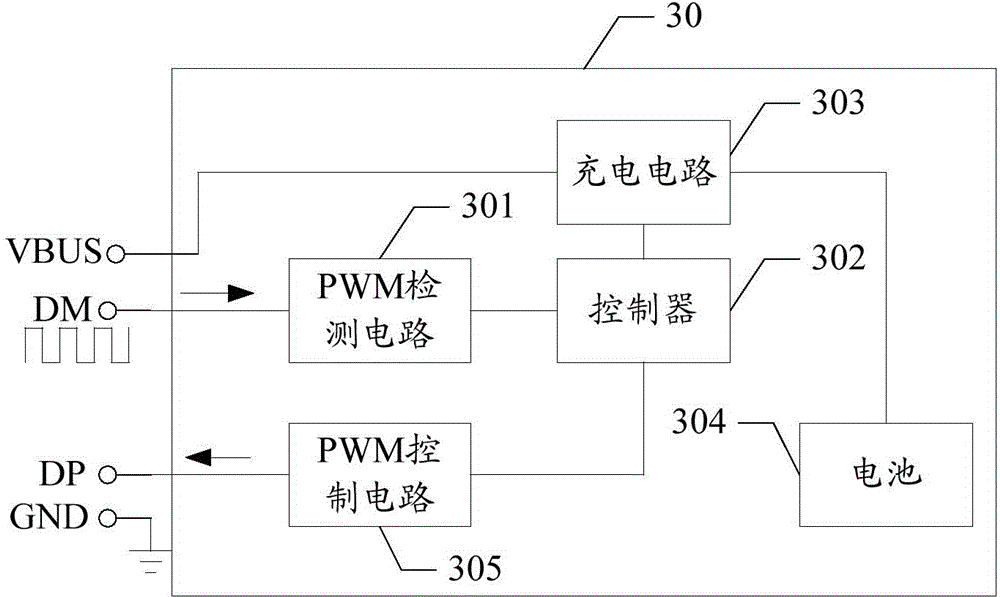

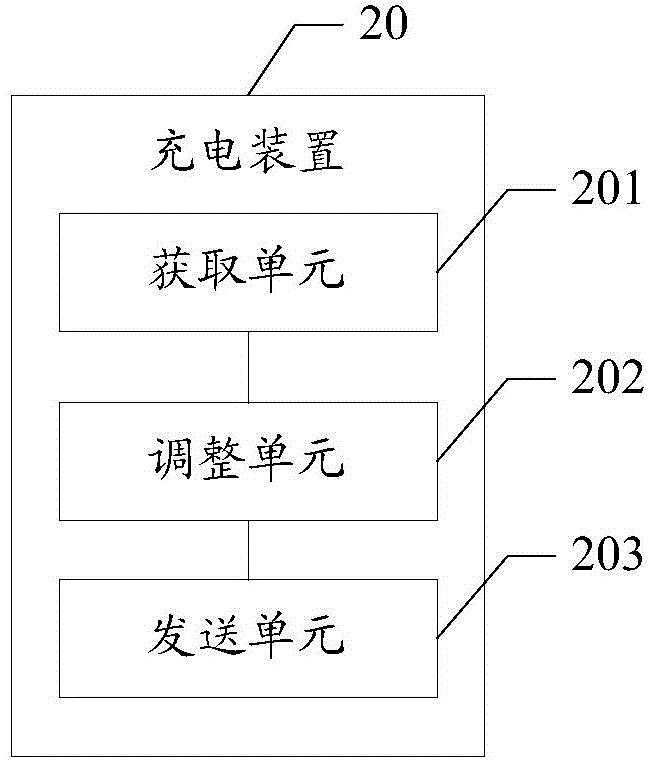

Charging method and device of equipment to be charged, equipment to be charged and charging system

ActiveCN104467135AFast chargingReduce consumptionSecondary cells charging/dischargingElectric powerCharge currentCharged current

The invention discloses a charging method and device of equipment to be charged, the equipment to be charged and a charging system. The charging method includes the steps that when a signal, representing a current rated output current value, transmitted by a charger is received, the current rated output current value of the charger is obtained; according to the current rated output current value of the charger, a preset charging current value of the equipment to be charged is adjusted, and charging is performed at an adjusted charging current value; a signal representing a needed voltage value is transmitted to the charger so that voltage corresponding to the needed voltage value signal can be output through the charger. By the adoption of the method, the device, the equipment to be charged and the charging system, under the condition that the output current of the charger is large, the charging capacity of the charger can be sufficiently utilized for achieving rapid charging.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

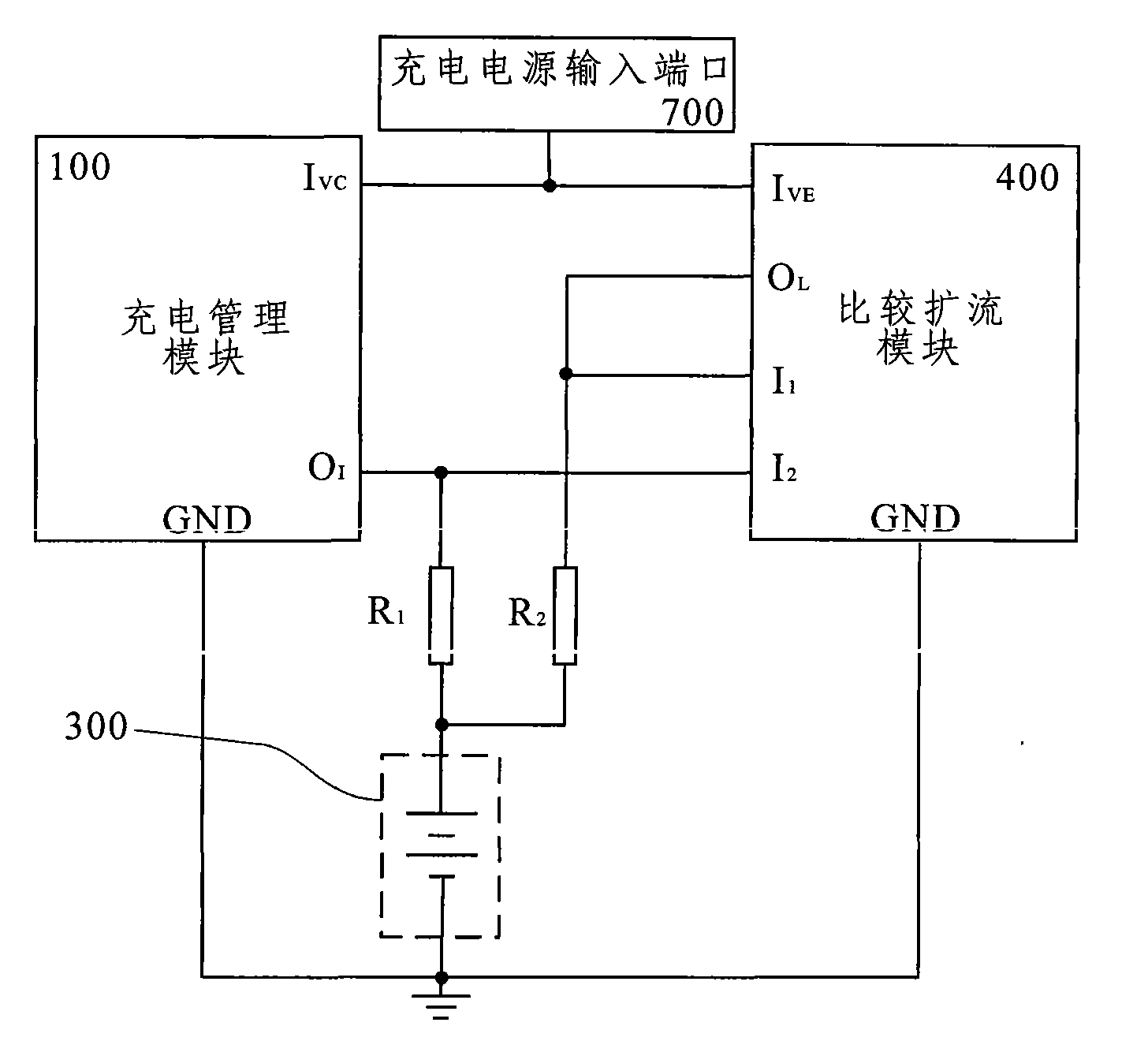

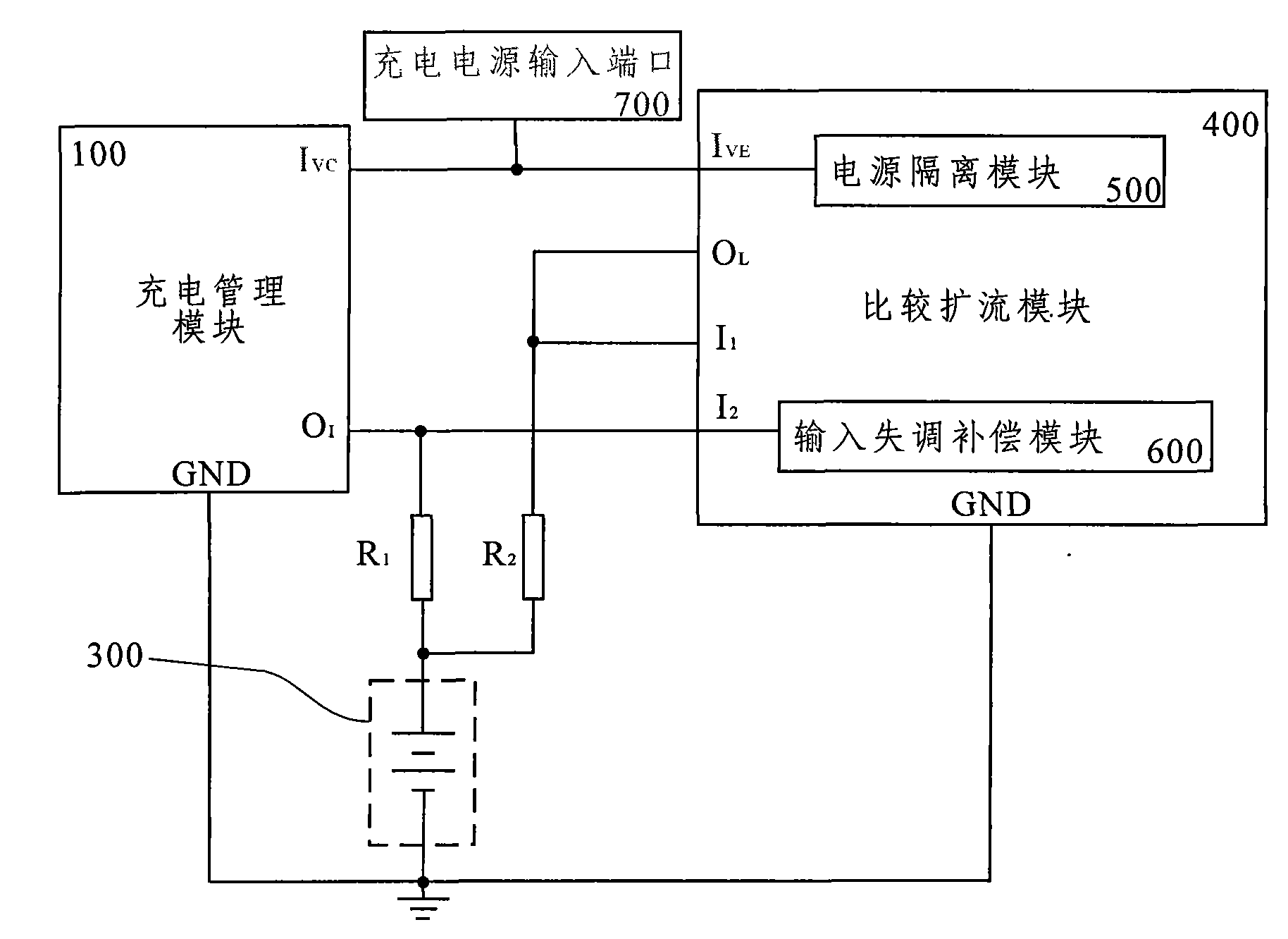

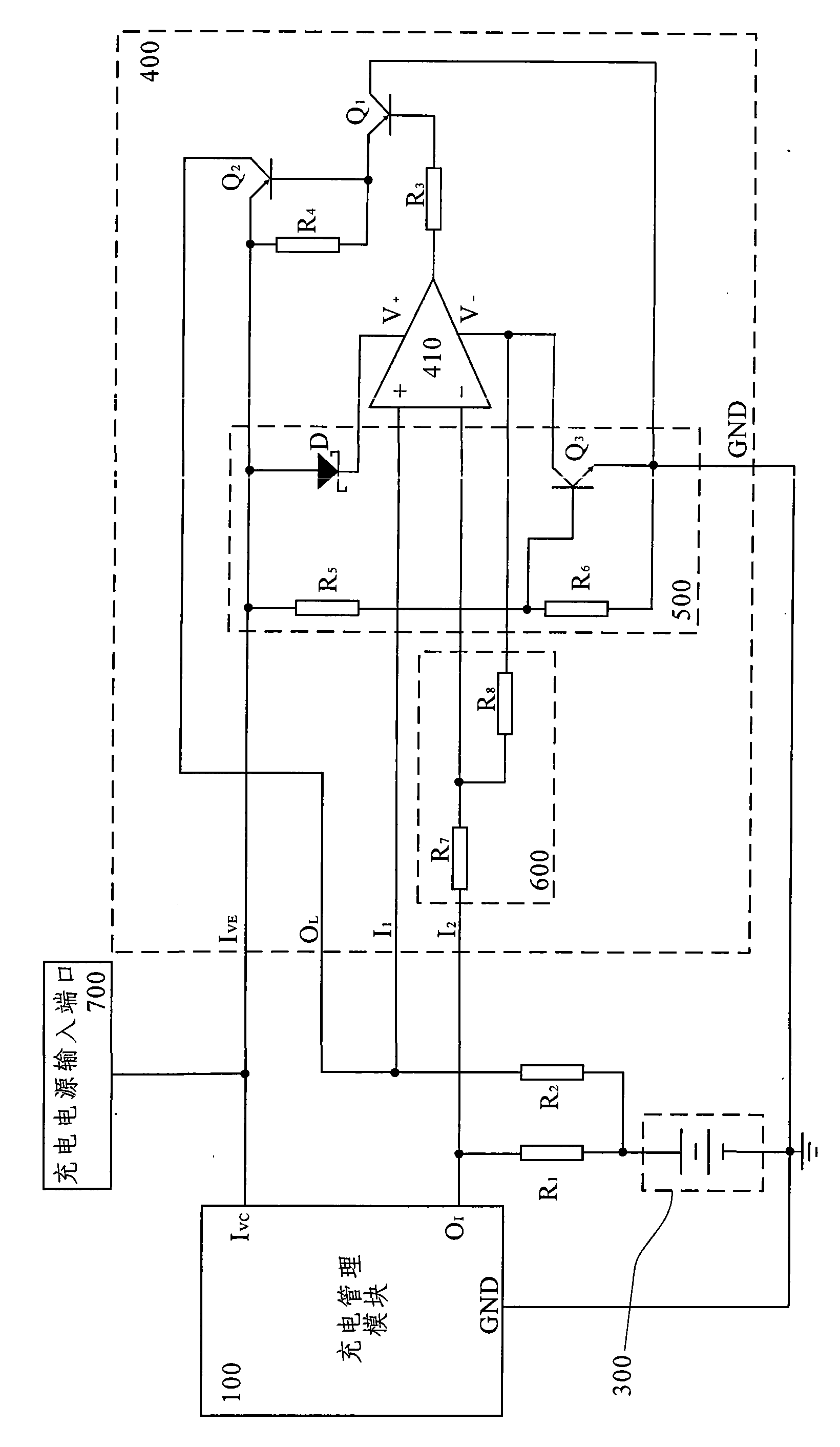

Current amplification quick charge circuit used for hand-hold electronic device

ActiveCN101662162ASimple structureSave spaceBatteries circuit arrangementsElectric powerElectrical resistance and conductanceCharge current

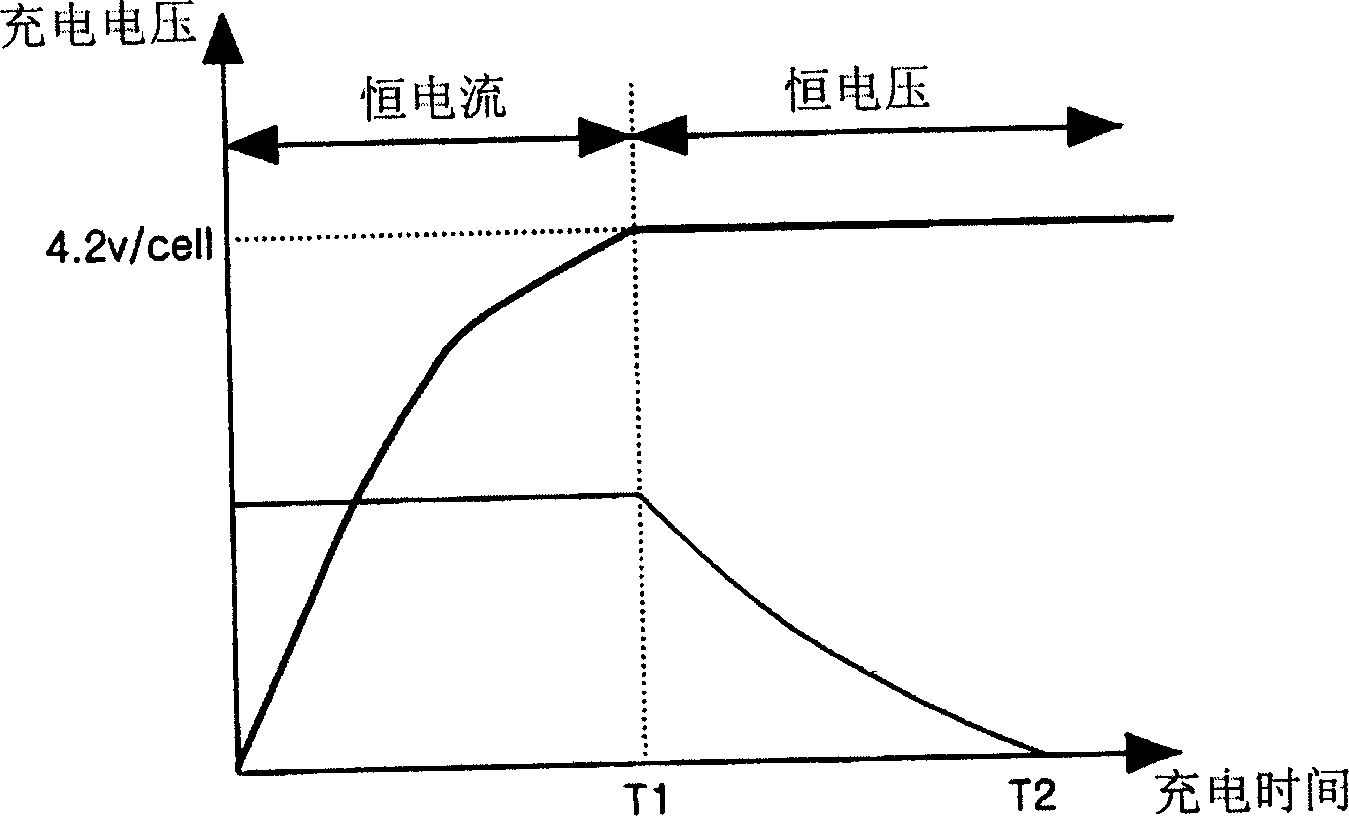

A current amplification quick charge circuit used for a hand-hold electronic device comprises a charge management module which is integrated inside a master chip of the hand-hold electronic device orembedded independently, and a rechargeable battery, particularly comprises a basic charging current sampling resistor, a current amplification charging current sampling resistor and a comparation current amplification module; and when the charge management module charges the rechargeable battery, the comparation current amplification module outputs the amplified current from a current amplificaiton output port according to the voltage difference between two comparing input ports. The current amplification quick charge circuit has simple structure, occupies small space of a printed circuit board, greatly improves the practical charging current to the rechargeable battery according to proportion by the two sampling resistors and the comparation current amplification module, improves chargingspeed, satisfies the charging requirement to high-capacity rechargeable batteries, simultaneously keeps the charge management module to conduct three-stage charge, namely, low current precharge stage, constant current charge stage and constant voltage charge stage, to the rechargeable battery, and is beneficial to maintaining the service life of the rechargeable battery.

Owner:SUNWODA ELECTRONICS

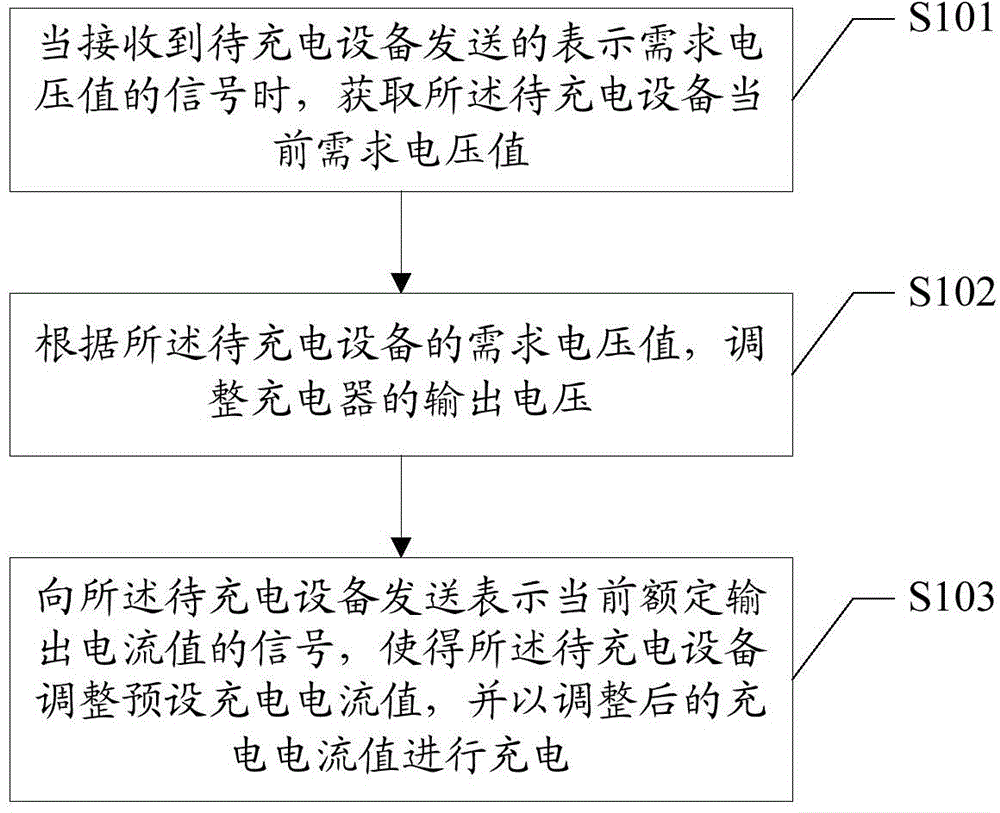

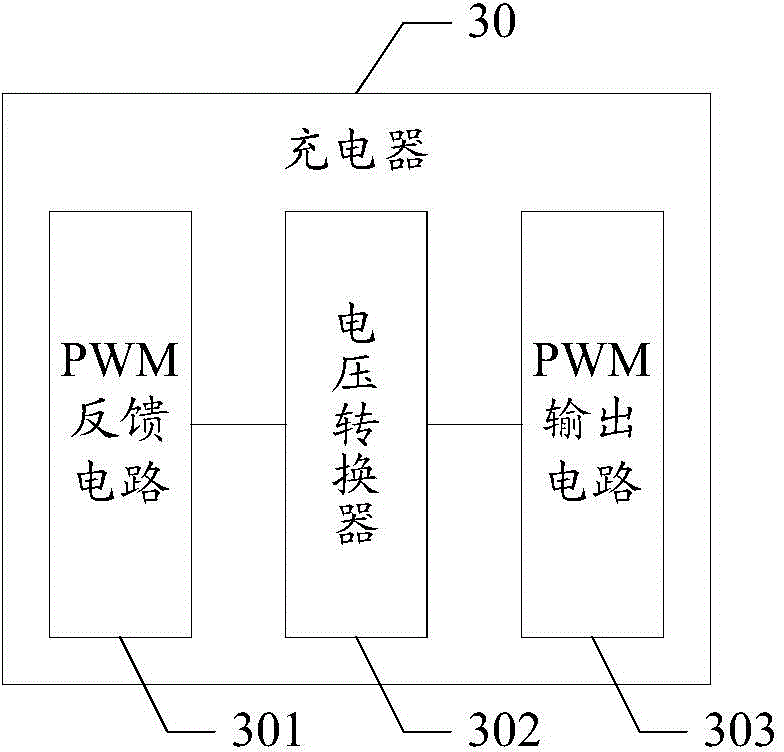

Charging method and device and charger

ActiveCN104467117AIncrease output powerIncrease charging currentBatteries circuit arrangementsSecondary cells charging/dischargingCharge currentCharged current

The invention discloses a charging method and device and a charger. The charging method includes the steps that when a signal, representing a needed voltage value, transmitted by equipment to be charged is received, the current needed voltage value of the equipment to be charged is obtained; according to the needed voltage value of the equipment to be charged, the output voltage of the charger is adjusted; a signal representing a current rated output current value is transmitted to the equipment to be charged so that the equipment to be charged can adjust a preset charging current value of the equipment to be charged according to the current rated output current value, and charging can be performed at an adjusted charging current value. By the adoption of the charging method and device and the charger, the charging capacity of the charger can be sufficiently utilized for achieving rapid charging.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

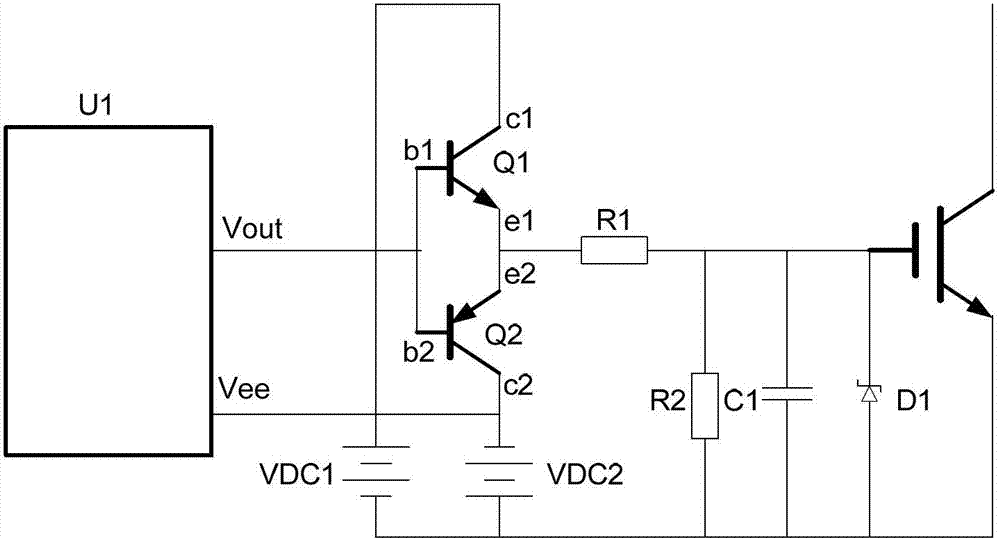

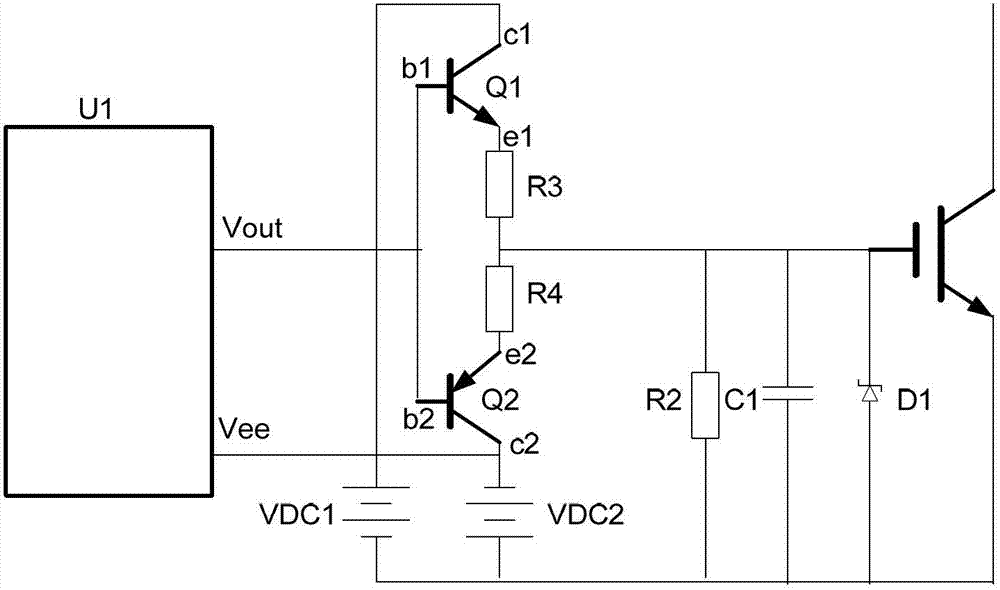

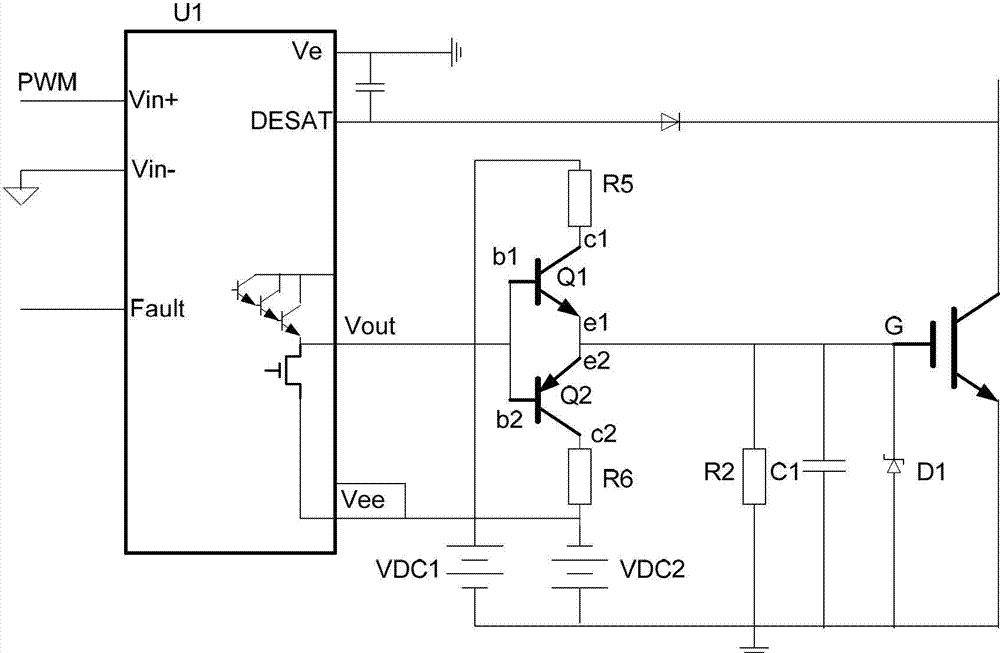

Insulated gate bipolar transistor (IGBT) driving push-pull circuit

InactiveCN102739211AIncrease charging currentIncrease discharge currentElectronic switchingCharge currentPower flow

The invention discloses an insulated gate bipolar transistor (IGBT) driving push-pull circuit, which mainly comprises an NPN triode (Q1), a PNP triode (Q2), a charging resistor (R5) and a discharging resistor (R6), wherein one end of the charging resistor (R5) is connected to an anode of an input power supply (VDC1), and the other end of the charging resistor (R5) is connected to a collector (c1) of the NPN triode (Q1); an emitter (e1) of the NPN triode (Q1) and an emitter (e2) of the PNP triode (Q2) are connected to form a point and connected with a gate (G) of an IGBT; the emitter (e2) of the PNP triode (Q2) is connected with one end of the discharging resistor (R6); and the other end of the discharging resistor (R6) is connected with the ground of a power supply (VDC2). By adoption of a push-pull circuit structure, in the turn-on moment of the IGBT, the NPN triode works in a saturation area, charging current is improved, and the loss of the NPN triode is reduced; and in the turn-off moment of the IGBT, the PNP triode works in the saturation area, discharging current is improved, and the loss of the PNP triode is reduced.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Thin film transistor, array substrate and method for manufacturing the same

ActiveUS20080296575A1Increase currentReduce failureTransistorSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A thin film transistor for a thin film transistor liquid crystal display (TFT-LCD), an array substrate and manufacturing method thereof are provided. The thin film transistor comprises a source, a drain, and a channel region between the source and drain. A source extension region is connected with the source, a drain expanded region is connected with the drain, and the source extension region is disposed opposite to the drain extension region to form a channel extension region therebetween.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

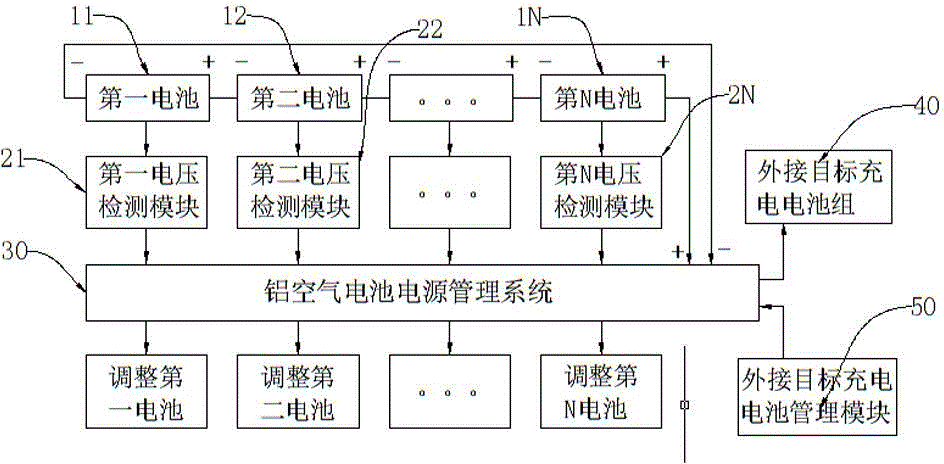

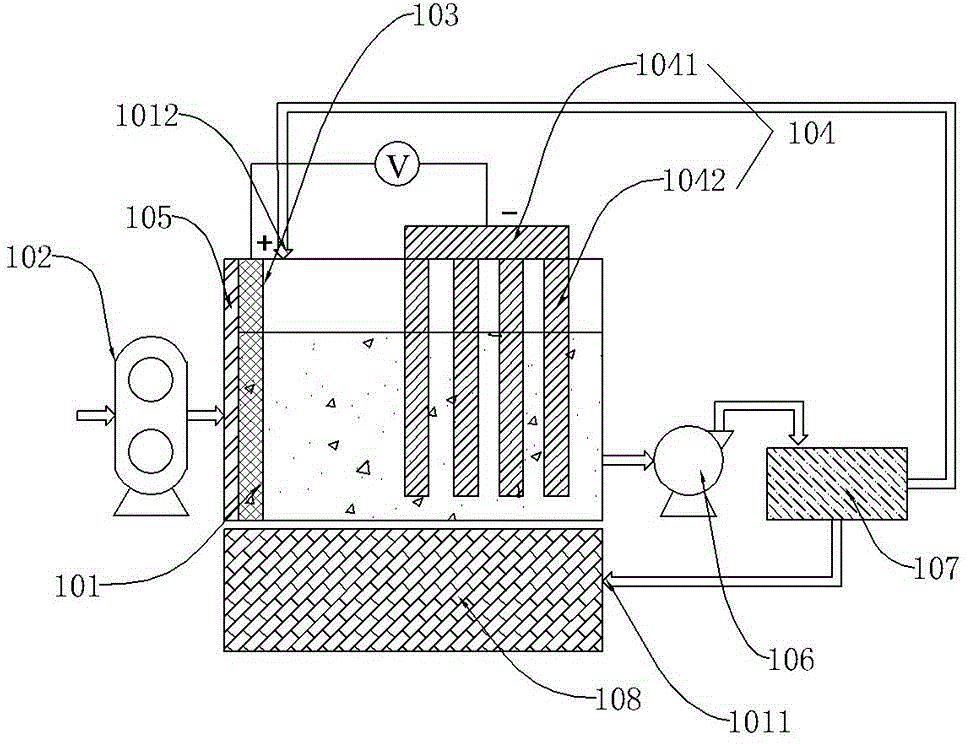

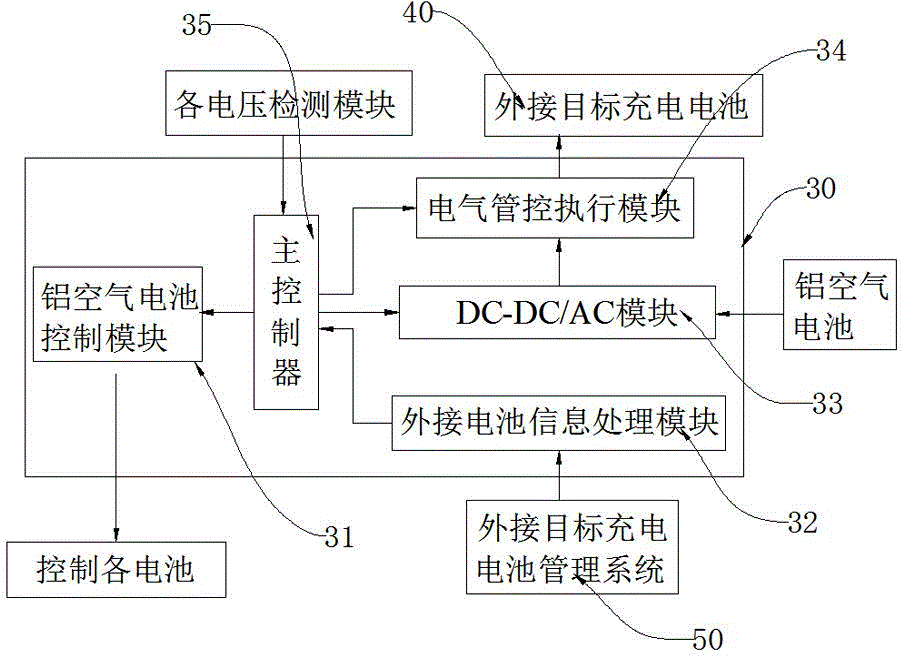

Special high-power charging equipment powered by aluminum-air batteries

ActiveCN104659880ALow costLarge charging currentBatteries circuit arrangementsElectric powerElectricityCharge current

The invention discloses special high-power charging equipment powered by aluminum-air batteries. The charging equipment comprises an aluminum-air battery power management system and multiple aluminum-air batteries, wherein the multiple aluminum-air batteries are electrically connected with the aluminum-air battery power management system after being in serial connection; the aluminum-air battery power management system converts electricity generated by the multiple aluminum-air batteries and conveys the electricity to an external target rechargeable battery, and the external target rechargeable battery starts a charging state. The equipment further comprises multiple voltage detection modules which input detected information of the aluminum-air batteries to a master controller in the aluminum-air battery power management system, the operation conditions of the aluminum-air batteries are adjusted by an aluminum-air battery control module, so that the external target rechargeable battery can be charged. The charging equipment does not need an external power grid, is free from geographical limitations and does not need capacity of any power grid, energy is supplied by aluminum and air which are easy to obtain, the charging current is strong, the equipment is movable, the investment cost is low, and massive stationing and networking are facilitated.

Owner:卢文浩 +2

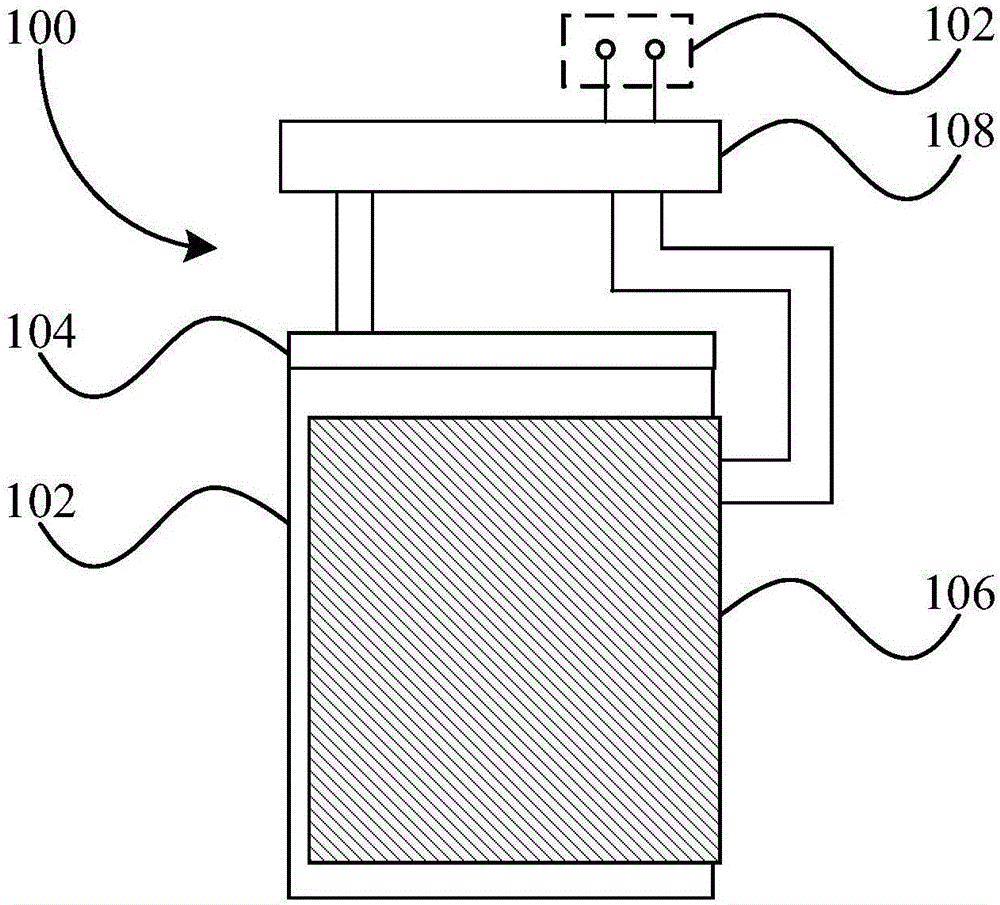

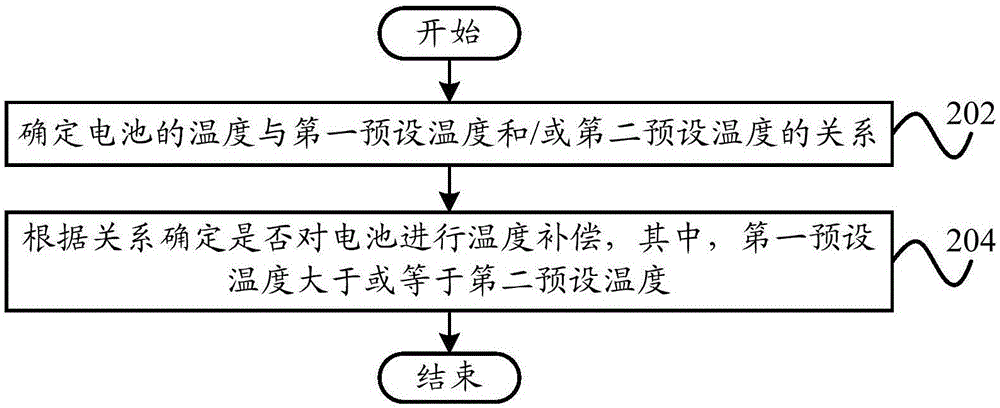

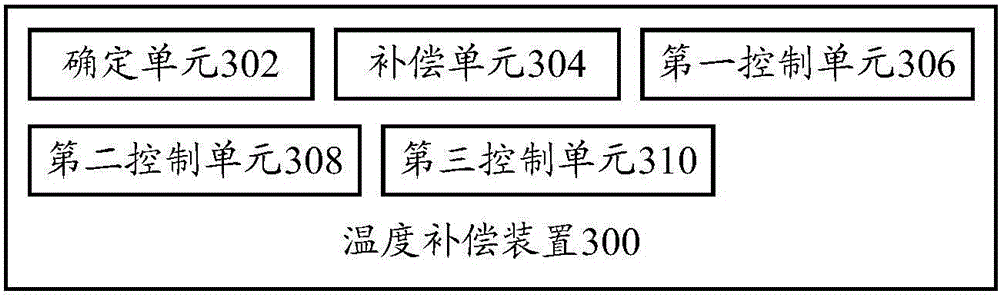

Temperature control device, temperature compensation method, temperature compensation device and terminal

InactiveCN106356915AExtend standby and use timeReduce the chance of security incidentsTemperatue controlElectric powerEngineeringSemiconductor

The invention provides a temperature control device, a temperature compensation method, a temperature compensation device and a terminal. The temperature control device comprises a battery and / or a charging terminal, a temperature detection element, a control chip and a temperature control semiconductor, wherein the temperature detection element makes contact with the battery and is used for detecting the temperature of the battery; the control chip is connected with the temperature detection element and used for detecting the relation between the temperature of the battery and a first preset temperature and / or a second preset temperature when receiving the temperature of the battery; the temperature control semiconductor is arranged in a heat exchange area of the battery and connected to the control chip and used for determining whether to perform temperature compensation on the battery according to a detection result of the control chip; the first preset temperature is higher than or equal to the second preset temperature. With adoption of the technical scheme, the charging time can be shortened, the charging volume of the battery can be increased, the standby time and use time of the terminal can be prolonged, and the use experience of a user is improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

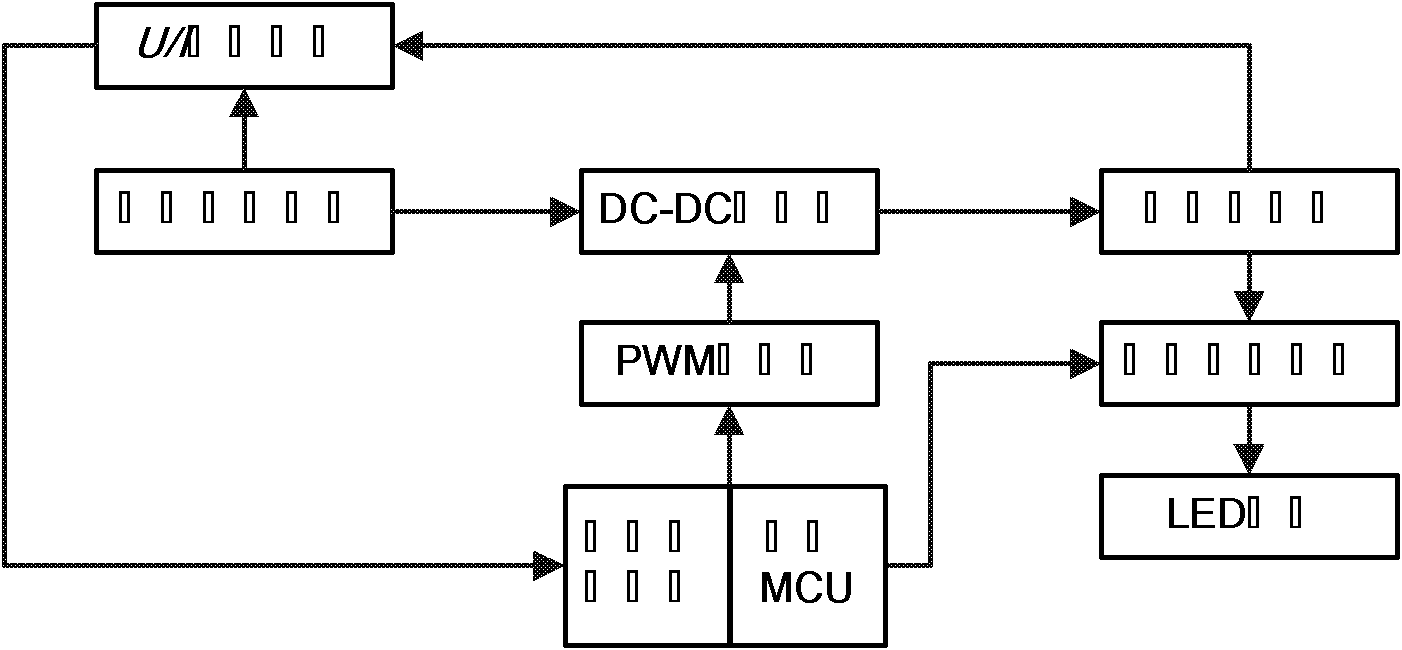

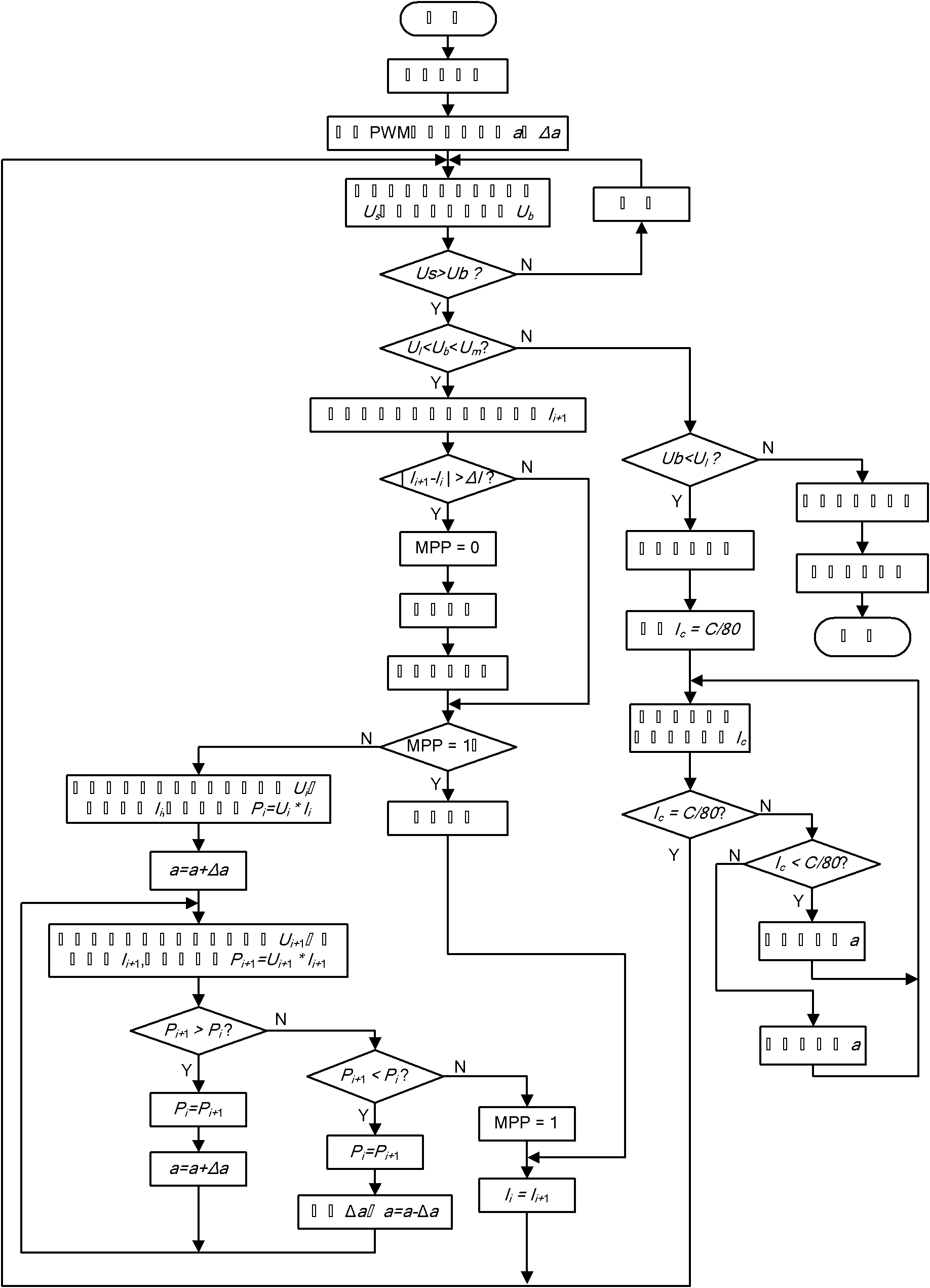

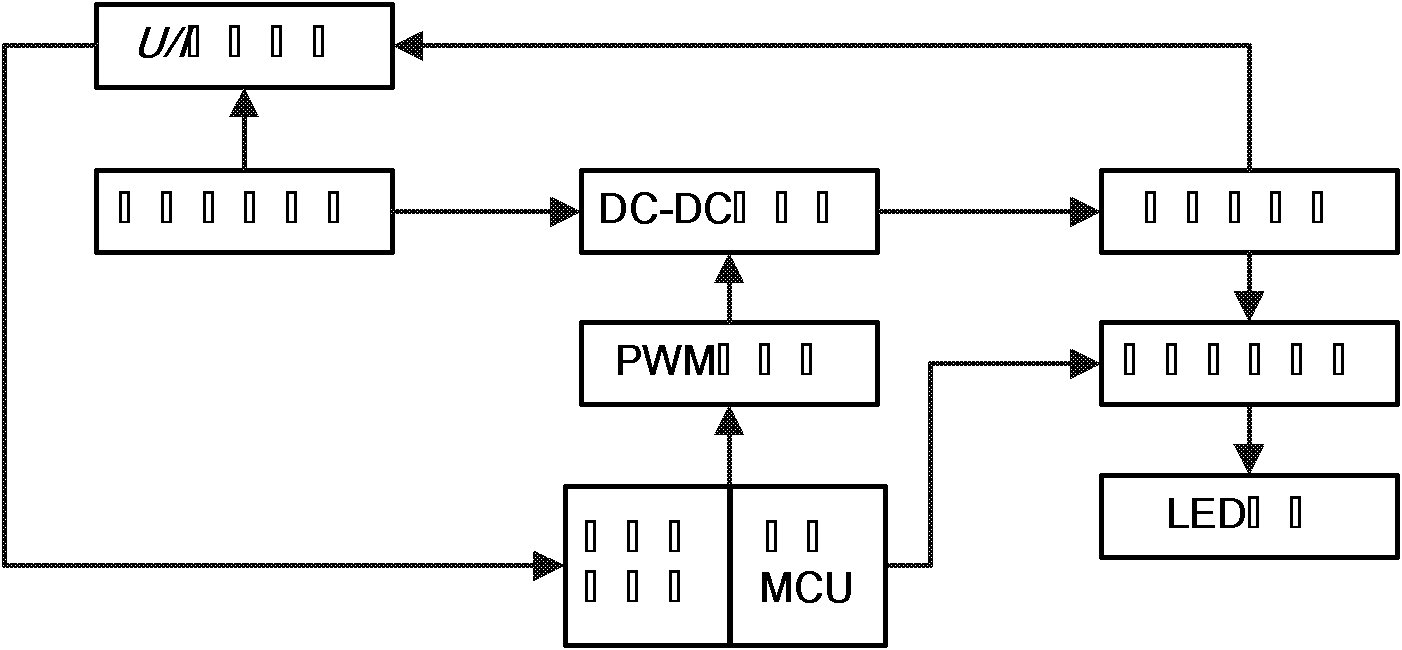

Charge control method of low-power independent photovoltaic generating system

InactiveCN101860061AImprove absorbencyRealize the charging systemBatteries circuit arrangementsElectric powerElectric energyCharge current

The invention discloses a charge control method of a low-power independent photovoltaic generating system, belonging to the technical field of photovoltaic power generation. In the method, the charge efficiency of the independent photovoltaic generating system is improved by fully utilizing the output characteristic of the photovoltaic battery array and the charge characteristic of the lead-acid storage battery, optimum matching of the photovoltaic battery array and the lead-acid storage battery is realized, meanwhile, the acceptable charge current of the lead-acid storage battery is strengthened through self discharge of the lead-acid storage battery and the lead-acid storage battery is ensured to completely absorb the electric energy output by the photovoltaic battery array during charging, thus achieving the aim of improving the charge efficiency of the independent photovoltaic generating system.

Owner:CENT SOUTH UNIV

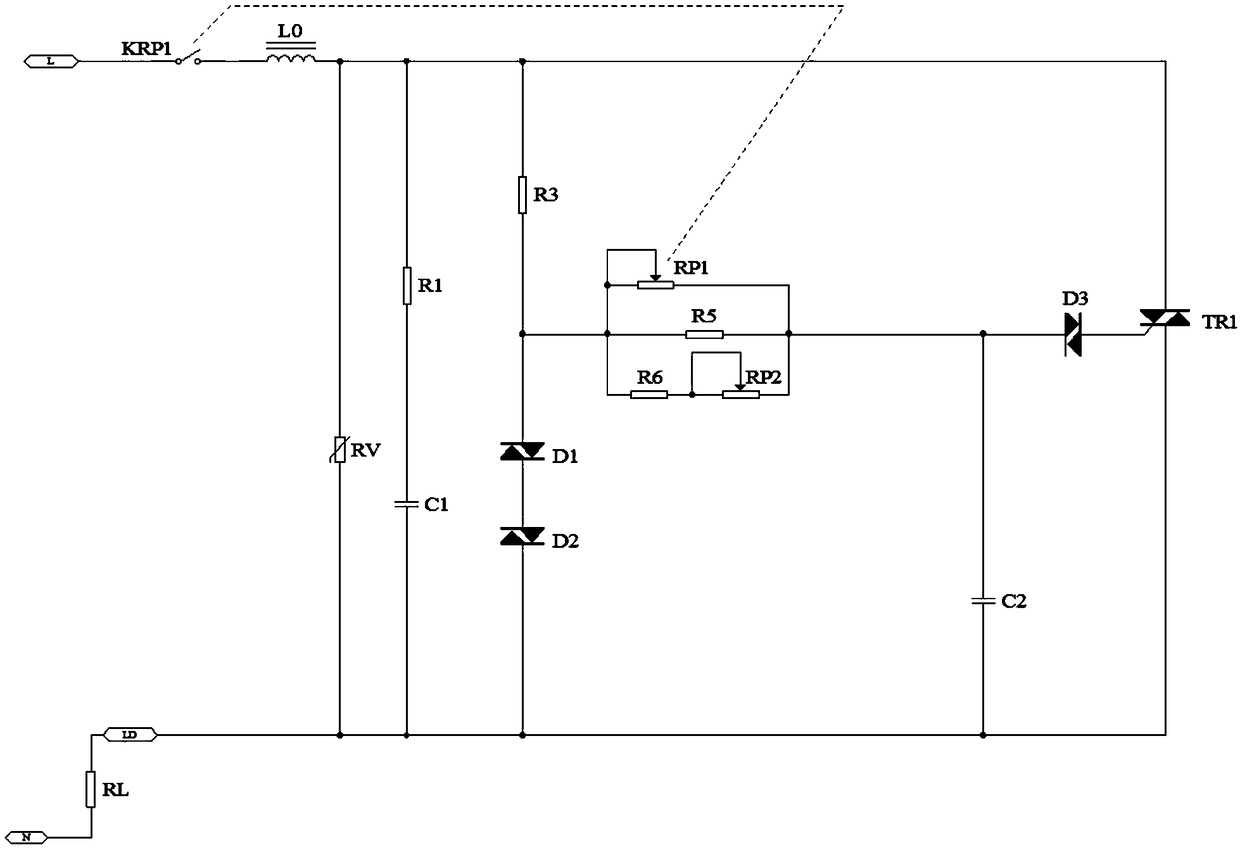

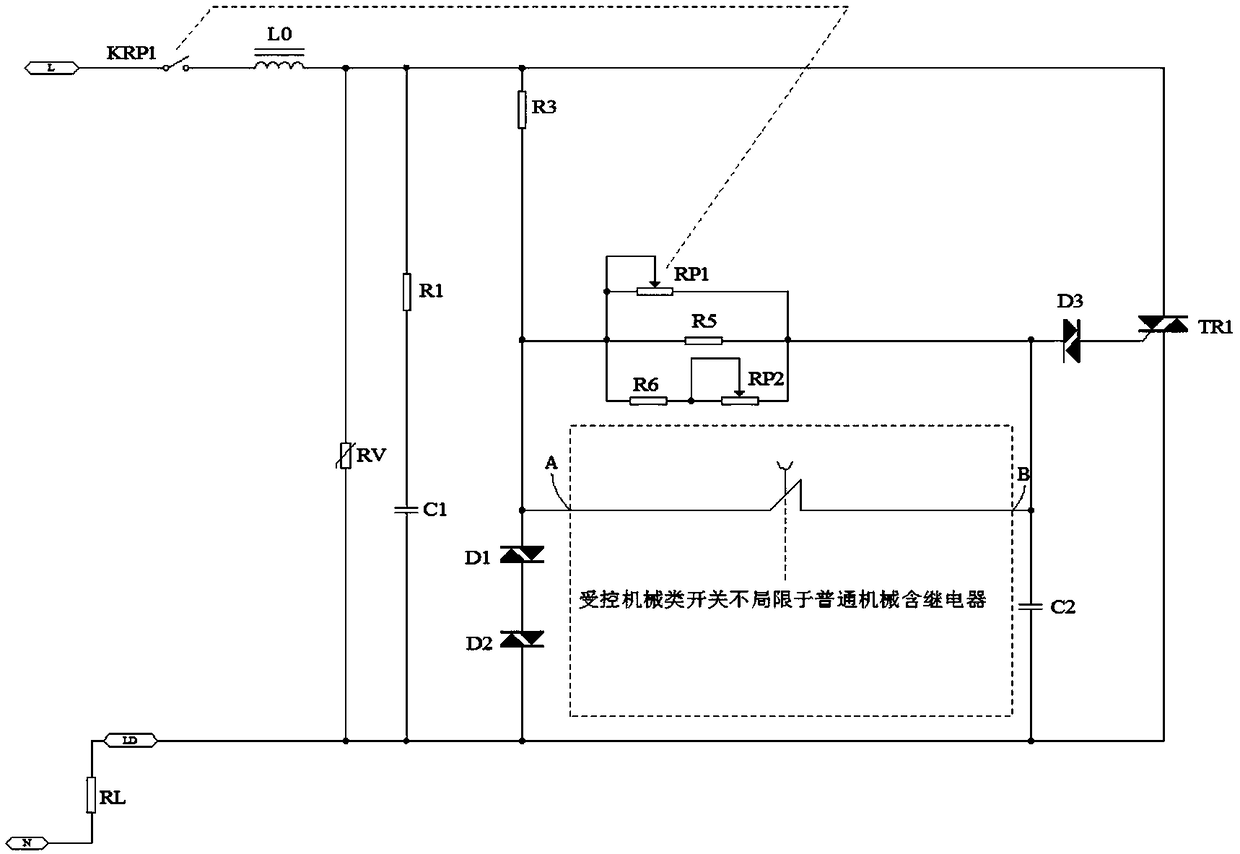

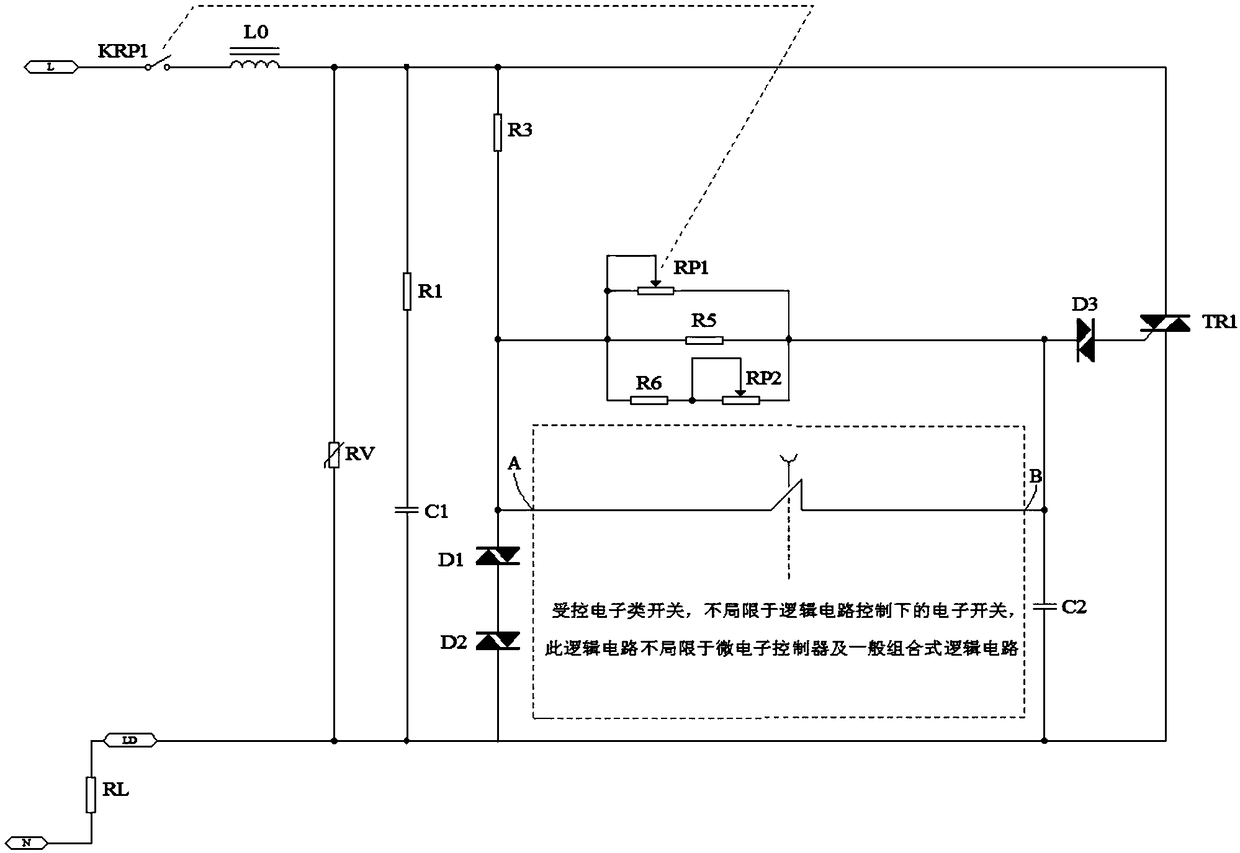

A light and speed regulating circuit

PendingCN109246904AIncrease charging currentElectrical apparatusElectric light circuit arrangementSilicon-controlled rectifierNeutral line

The invention discloses a light and speed regulating circuit, which comprises a main trigger circuit connected in series between a fire line terminal and a neutral line terminal and used for regulating load brightness or load speed through an adjustable resistor network and a switch actuating element, and a compensation circuit connected in parallel with the adjustable resistor network; the compensation circuit provids current compensation to the adjustable resistor network for a period of time after the power switch is closed to satisfy the start-up current of the load and to continuously turn on the switch actuating element for the period of time; The power switch is connected with the fire line end; The switching actuator comprises a silicon-controlled rectifier, a MOS transistor, an IGBT and / or a thyristor. The invention makes the operation of the lamp in or close to the minimum self-sustaining brightness state of the lamp itself after the dimming switch is closed, or the fan be inthe minimum sustaining working current state after the speed regulator switch is closed, so as to solve the problems of dead stroke (invalid stroke) and inconvenience in use when starting the machine.

Owner:XIAMEN TENIA LIGHTING & ELECTRICAL

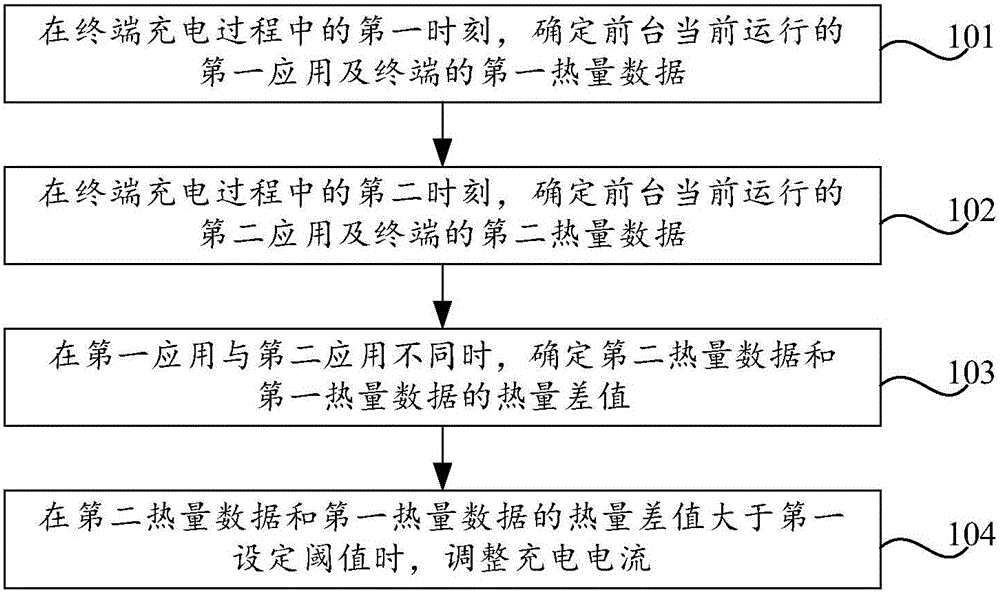

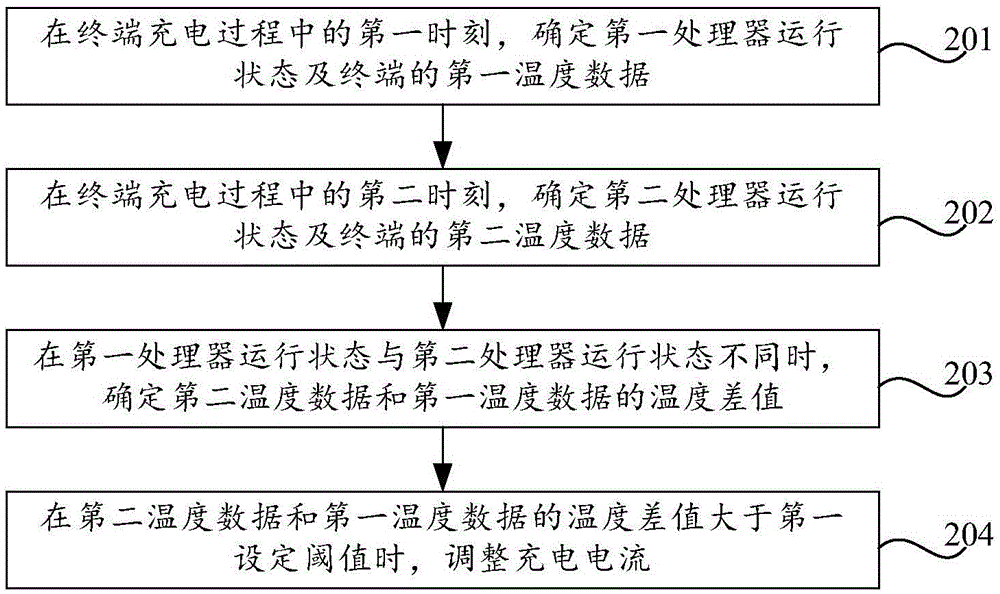

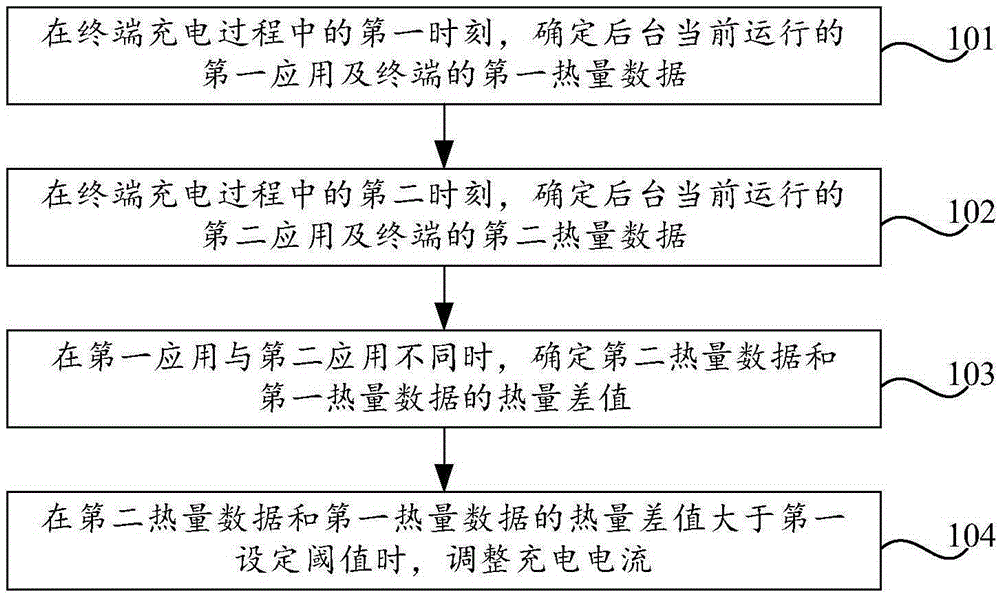

Terminal, charging method and device of terminal

ActiveCN105071500AImprove experienceIncrease charging rateBatteries circuit arrangementsSecondary cells charging/dischargingThermal energyCharge current

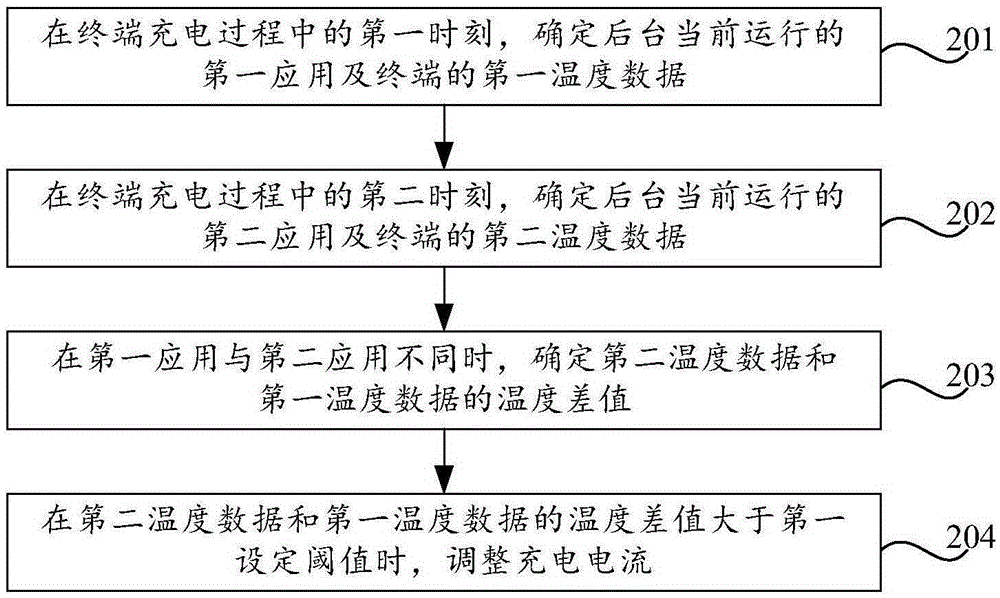

The invention relates to a terminal, a charging method and device of the terminal. The method includes the following steps that: a first application which operates currently and first heat energy data of the terminal are determined at a first time point in the charging process of the terminal; a second application which operates currently and second heat energy data of the terminal are determined at a second time point in the charging process of the terminal, the interval of the first time point and the second time point is a first time interval; when the first application is different from the second application, the difference value of the first heat energy data and the second heat energy data is determined; and when the difference value of the first heat energy data and the second heat energy data is larger than a first set threshold value, charging current is adjusted. With the charging method provided by the embodiment of the invention adopted, relatively constant charging current can be provided for the terminal, and the temperature of the terminal will not rise too fast assuredly, and the charging rate of the terminal when the terminal is being used can be improved, and user experience can be enhanced.

Owner:XIAOMI INC

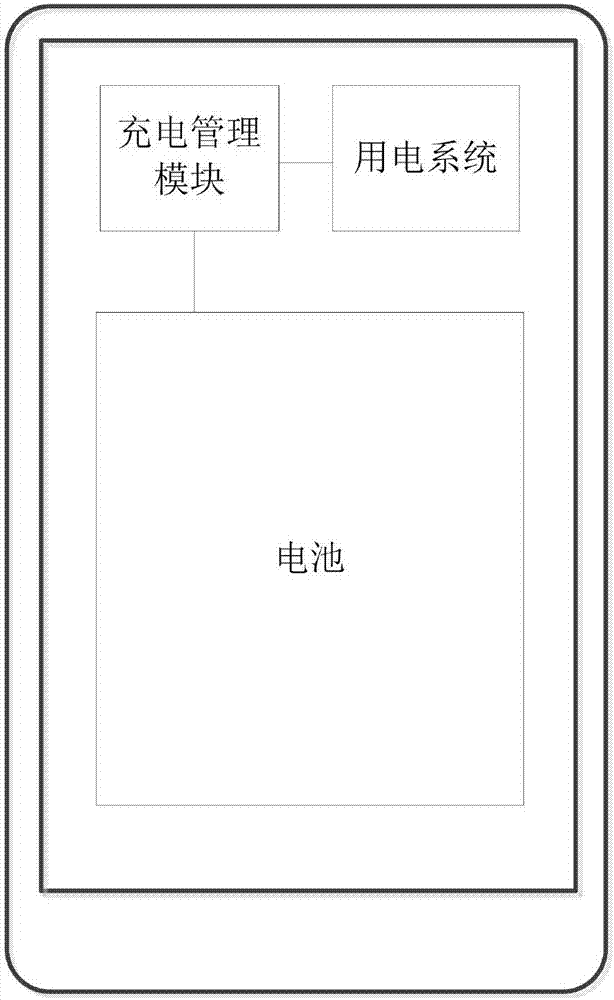

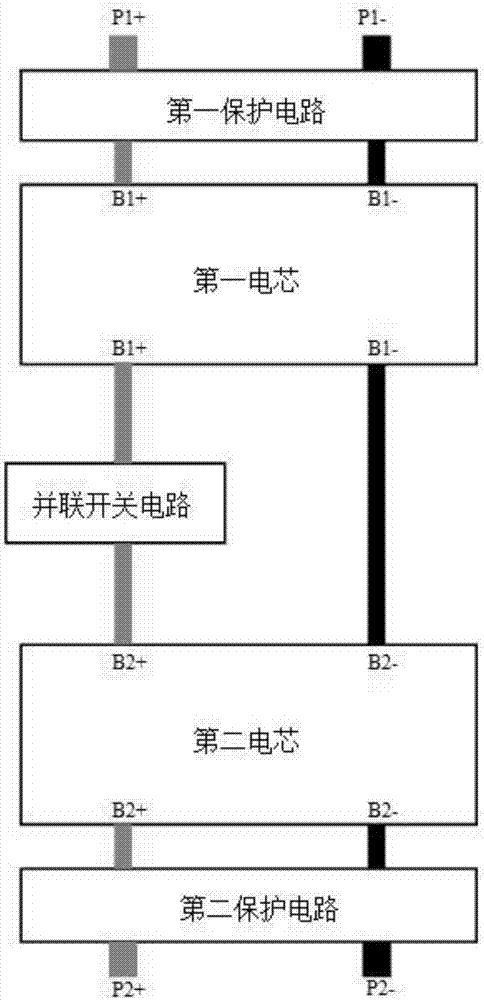

Charging method and charging system

ActiveCN106898833AReduce lossReduce feverSecondary cells charging/dischargingElectric powerCurrent thresholdEngineering

The invention provides a charging method and a charging system. The charging method comprises the following steps: during charging, judging whether a first connecting port of a battery is being discharged or not; when the first connecting port is being discharged, judging whether the power consumption current is higher than a current threshold or not; when the power consumption current is higher than the current threshold, disconnecting a first battery core from a second battery core of the battery, and charging the battery through a second connecting port of the battery; when the power consumption current is lower than the current threshold, supplying power to the outside through a charging management module, controlling the first connecting port to stop discharge, connecting the first battery core with the second battery core, and charging the battery through the second connecting port; and when the first connecting port is not discharged, connecting the first battery core with the second battery core, and charging the battery through the second connecting port. Through the charging method and the charging system, a power consuming system connected with one connecting port and the charging management module connected with another connecting port are separated by the battery, so that local overheating caused by heat superposition of the two heat sources is avoided.

Owner:QIKU INTERNET TECH SHENZHEN CO LTD

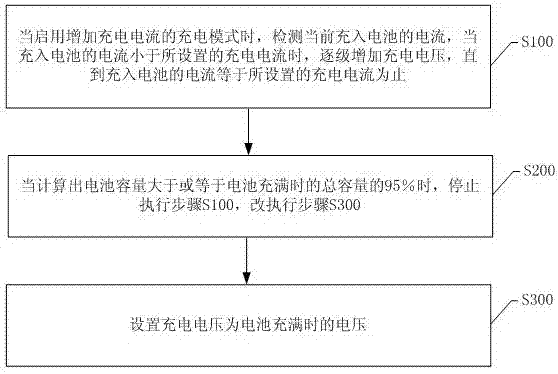

Mobile terminal, charging current processing method thereof and storage medium

InactiveCN107196373AImprove user experienceFast fullBatteries circuit arrangementsElectric powerElectricityCharge current

The invention discloses a mobile terminal, a charging current processing method thereof and a storage medium. The method comprises the following steps: when a user starts to use a charging mode of charging current, detecting current currently charging into a battery, when the current charged into the battery is smaller than set charging current, increasing charging voltage until the current charged into the battery is equal to the set charging current; and when the capacity of the battery is calculated to be greater than or equal to 95% of total capacity when the battery is fully charged, stopping current detection and the work of a voltage increasing module, and turning over to normal charging module work. When the mobile terminal urgently needs to be quickly charged, relatively high charging current can be maintained in the whole charging process, so that the effect of quickly charging the battery is reached, the user experience is promoted, and convenience is brought for the user.

Owner:TCL COMM TECH NINGBO CO LTD

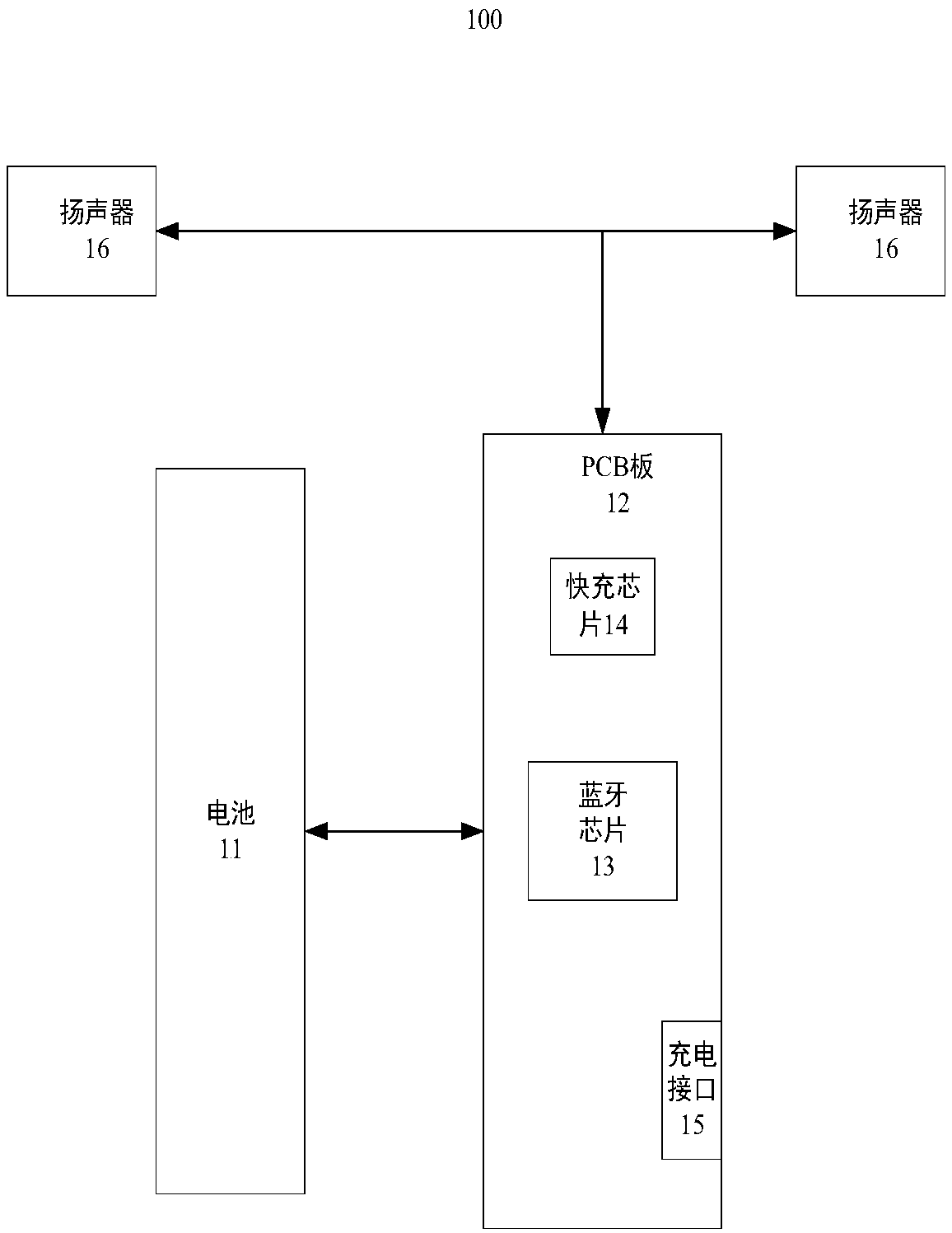

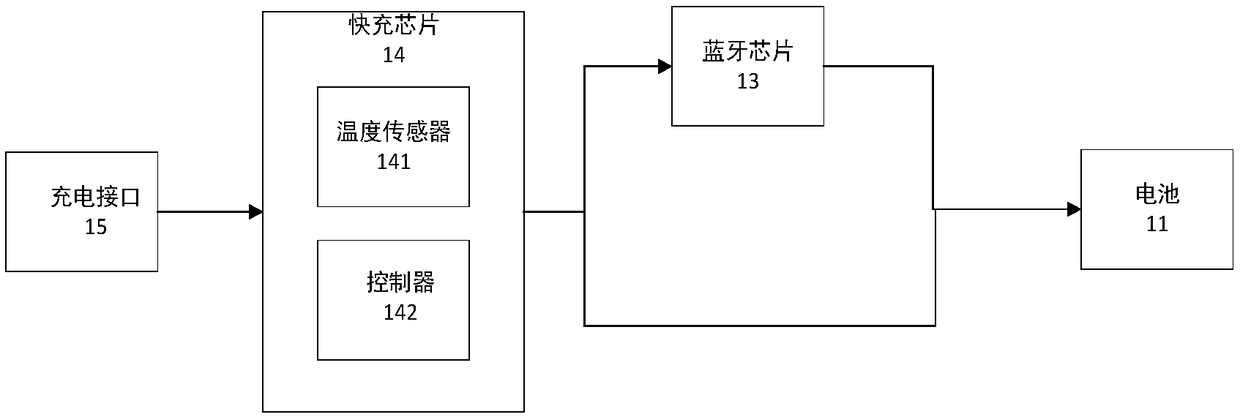

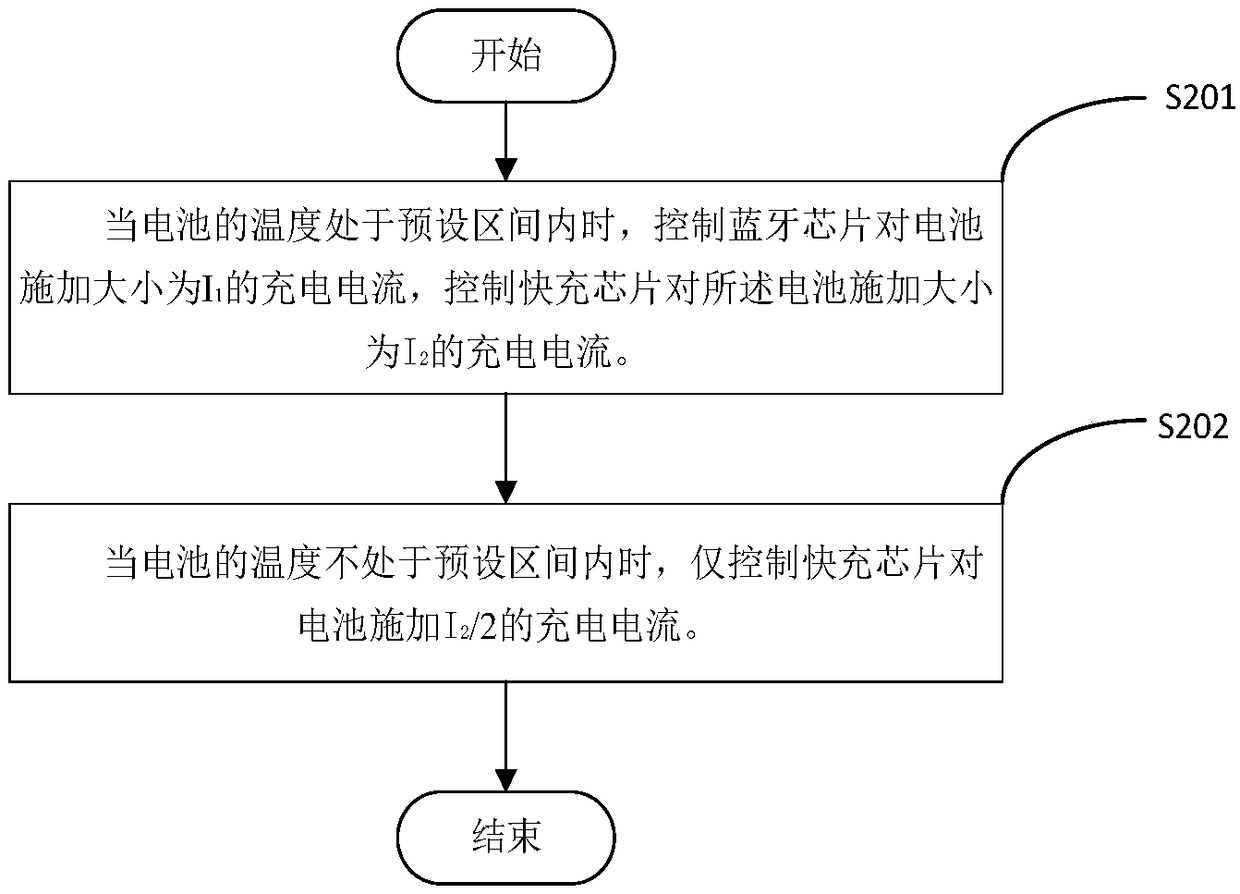

Bluetooth earphone and charging control method thereof

InactiveCN108879836AAvoid short circuitEnsure charging safetyNear-field systems using receiversElectric powerElectricityPower flow

Embodiments of the invention relate to the technical field of intelligent listening and wearing equipment, and disclose a Bluetooth earphone and a charging control method thereof. The Bluetooth earphone comprises a battery, a PCB electrically connected with the battery, a Bluetooth chip and a fast-charging chip, wherein the Bluetooth chip and the fast-charging chip are arranged on the PCB; when the temperature of the battery is within a preset interval, a charging current of I1 is applied to the battery by the Bluetooth chip; the fast-charging chip is used for charging the battery; when the temperature of the battery is within the preset interval, the fast-charging chip is used for applying a charging current of I2 to the battery; when the temperature of the battery is not within the preset interval, the fast-charging chip applies a charging current of less than I2 to the battery. According to the Bluetooth earphone and the charging control method thereof, rapid charging of the Bluetooth earphone can be realized.

Owner:GUANGZHOU KUGOU TECH

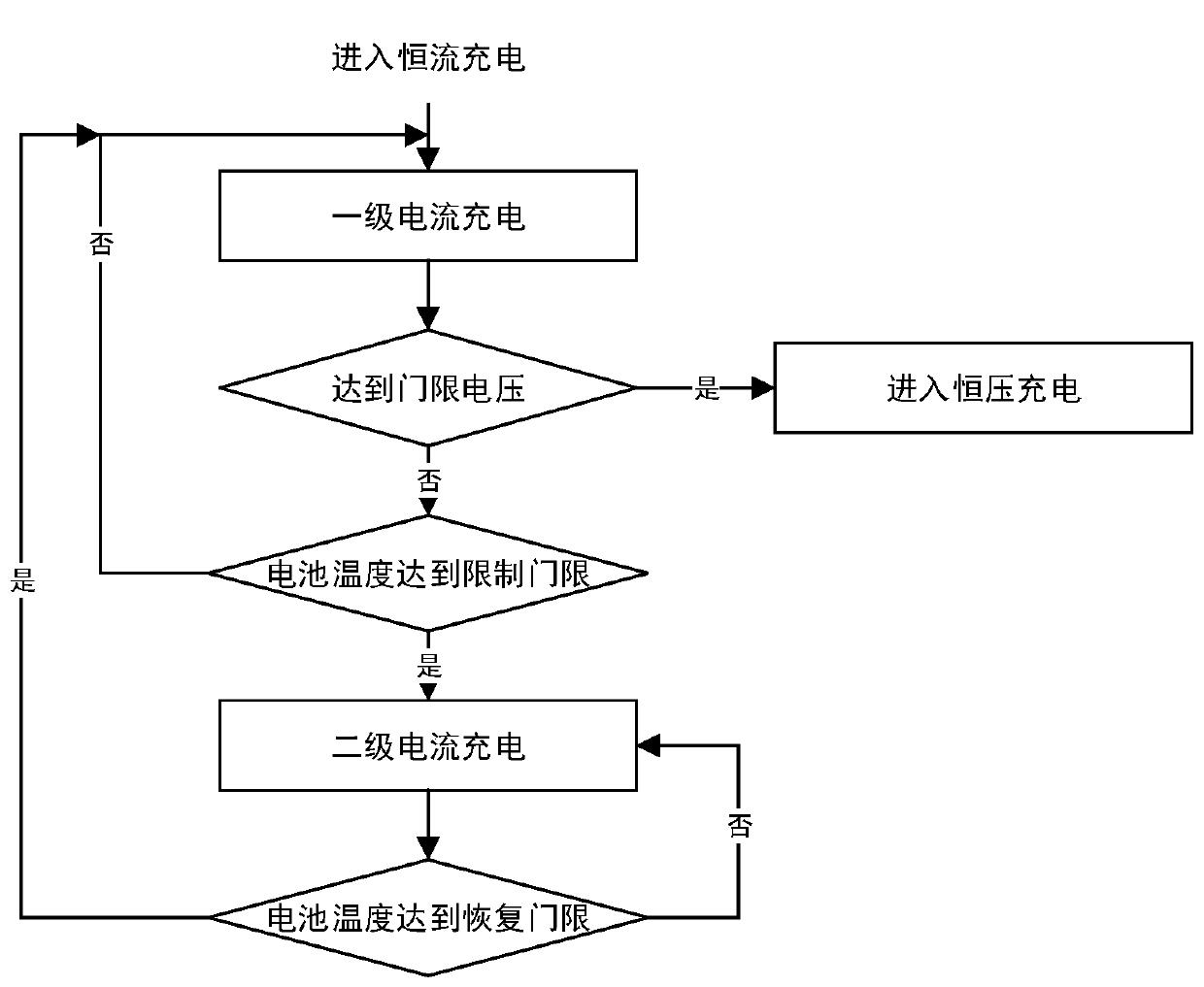

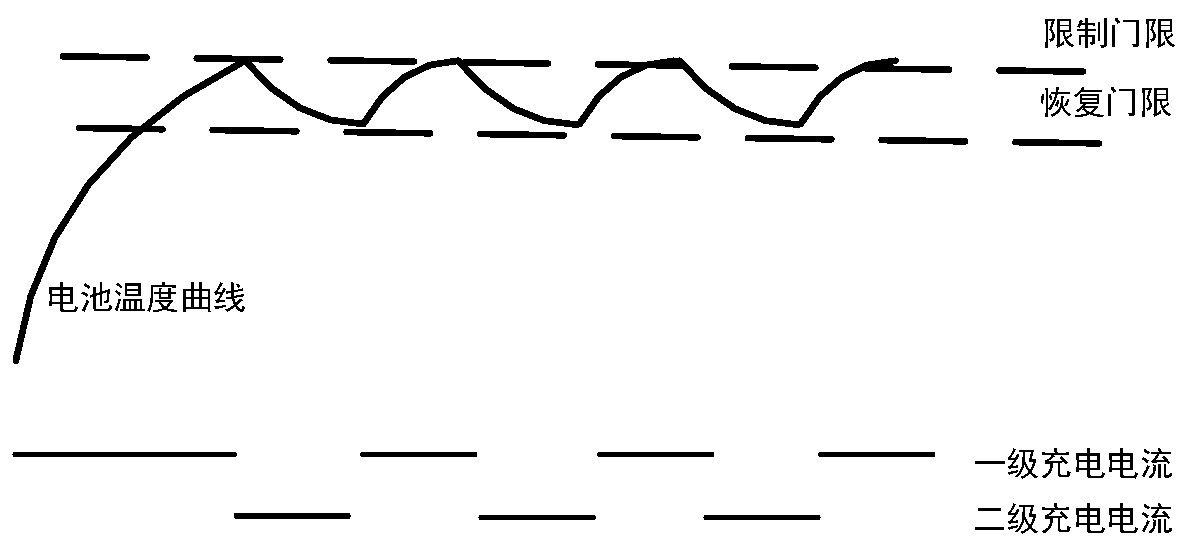

Charging method and device based on temperature monitoring

InactiveCN111342513AIncrease charging currentShorten charging timeBatteries circuit arrangementsSecondary cells charging/dischargingThermodynamicsCharge current

The invention aims to provide a charging method and device based on temperature monitoring. By monitoring the temperature of a battery of the device, setting a limit threshold temperature (slightly lower than the over-temperature protection temperature of the battery) and restoring the threshold temperature, the battery maintains the higher charging current for a long time at the constant-currentcharging stage and under the condition of ensuring that the temperature of the battery of the device does not exceed the standard, the overall charging current at the constant-current stage is improved, and the charging time is shortened. According to the invention, the charging speed and the temperature rise can be considered simultaneously in the quick charging process. The method and the devicecan be applied to the field of consumer electronics, in particular to the small-sized or miniature electronic devices.

Owner:SHANGHAI LONGCHEER TECH CO LTD

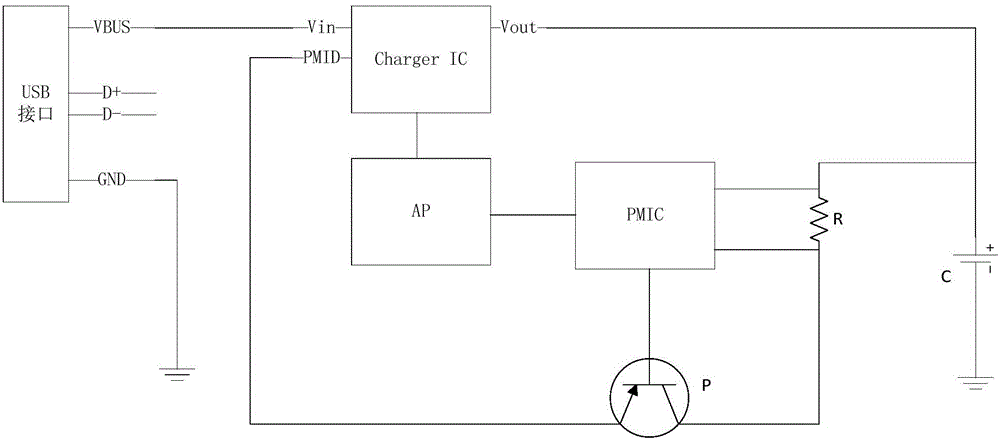

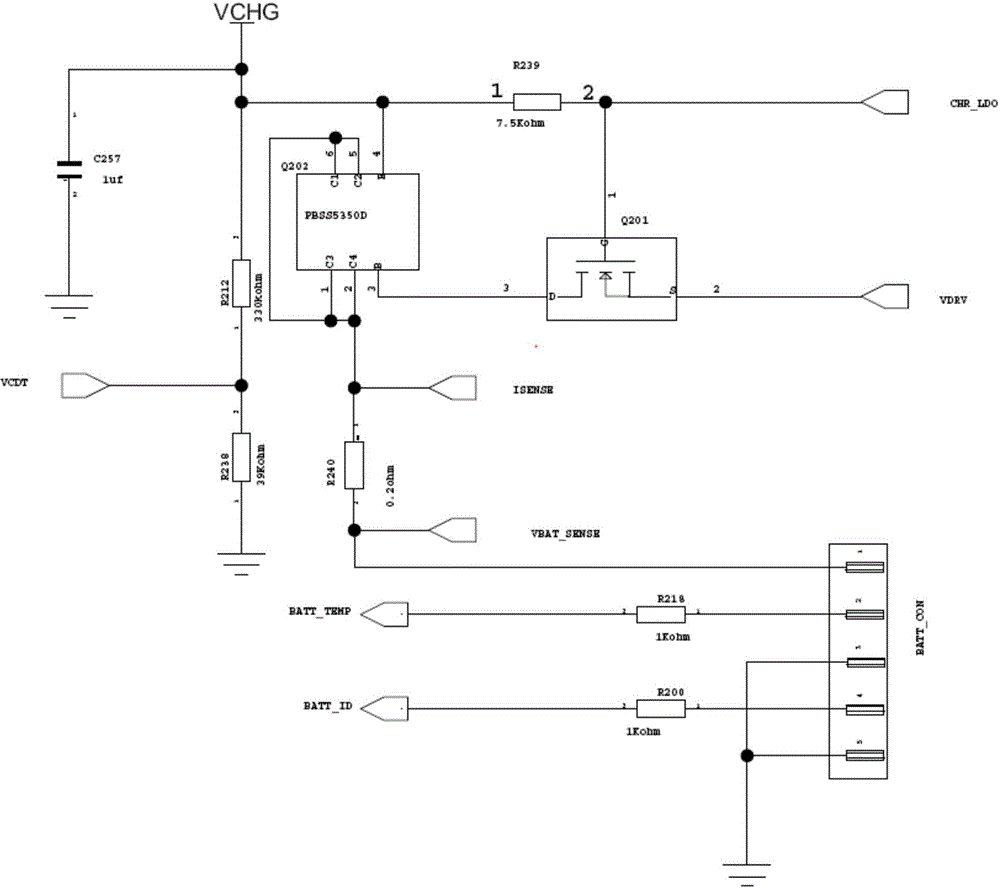

Mobile terminal and charging circuit thereof

InactiveCN105978122AIncrease charging currentReduce the temperatureBatteries circuit arrangementsElectric powerPower flowSupply management

The invention discloses a charging circuit of a mobile terminal. The charging circuit comprises a USB interface, a switch charging module which is connected with the USB interface, a processing control module which is connected with the switch charging module, a power supply management module which is connected with the processing control module, a triode which is connected with the switch charging module and the power supply management module, a resistor which is connected with the power supply management module and the triode, and a battery which is connected with the switch charging module and the resistor. According to the charging circuit of the mobile terminal, the switch charging module and a linear charging circuit formed by integration of the power supply management module are simultaneously configured to start charging so as to realize two-path parallel charging. Charging current is enhanced, and the generated heat is dispersed to two charging circuits so as to achieve the effect of temperature reduction.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

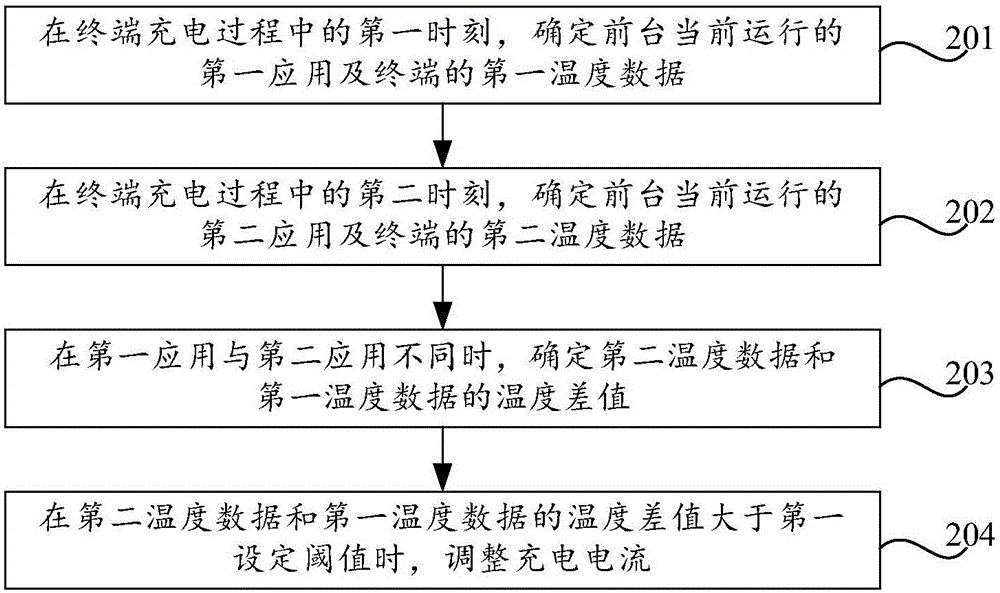

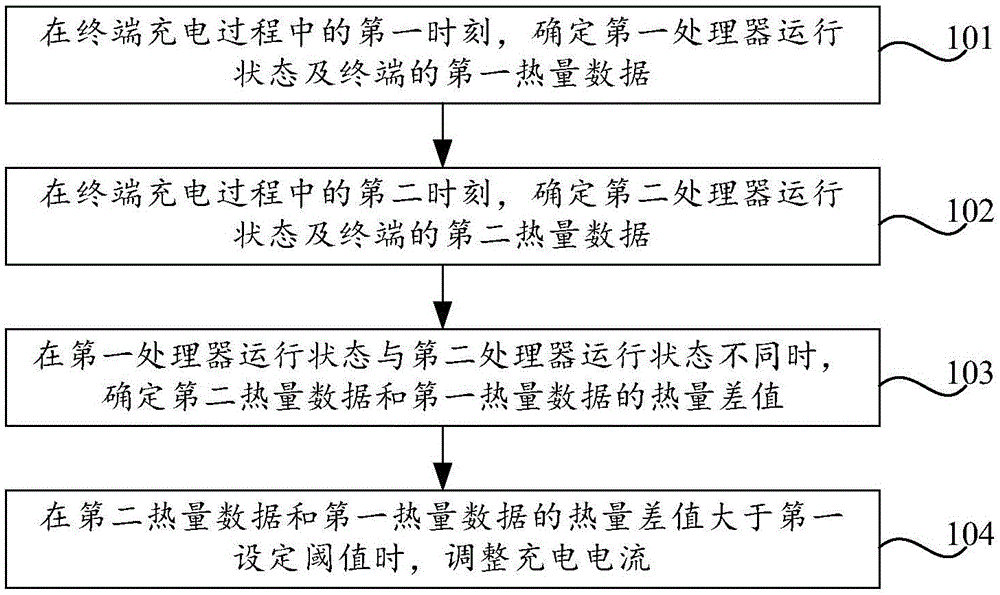

Method and device for charging terminal and terminal

ActiveCN105070965AImprove experienceIncrease charging rateBatteries circuit arrangementsSecondary cells charging/dischargingCharge currentCharge rate

The invention relates to a method and a device for charging a terminal and the terminal. The method comprises the following steps: at the first moment in the terminal charging process, determining an operating state of a first processor of the terminal and first heat energy data of the terminal; at the second moment in the terminal charging process, determining the operating state of a second processor of the terminal and second heat energy data of the terminal; when the operating state of the first processor is different from that of the second processor, determining a difference value between the second heat energy data and the first heat energy data; and when the difference value between the second heat energy data and the first heat energy data is greater than a first set threshold, regulating charging current. Through application of the method and the device, relatively constant charging current can be provided for the terminal; the condition that the temperature of the terminal does not rise too fast is ensured; the charging rate in the process of using the terminal while charging is increased; and the user experience is improved.

Owner:XIAOMI INC

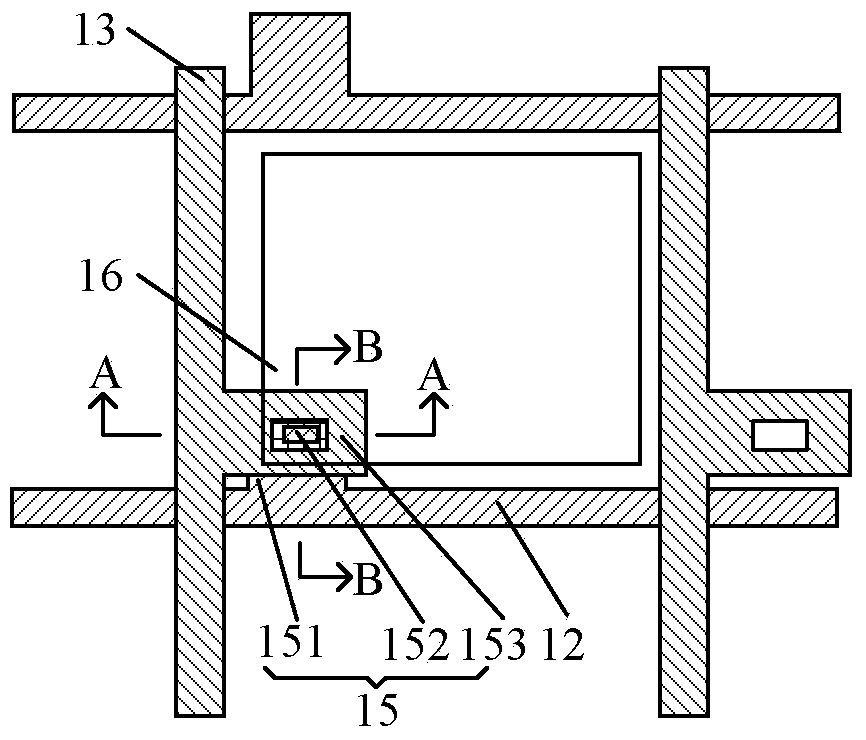

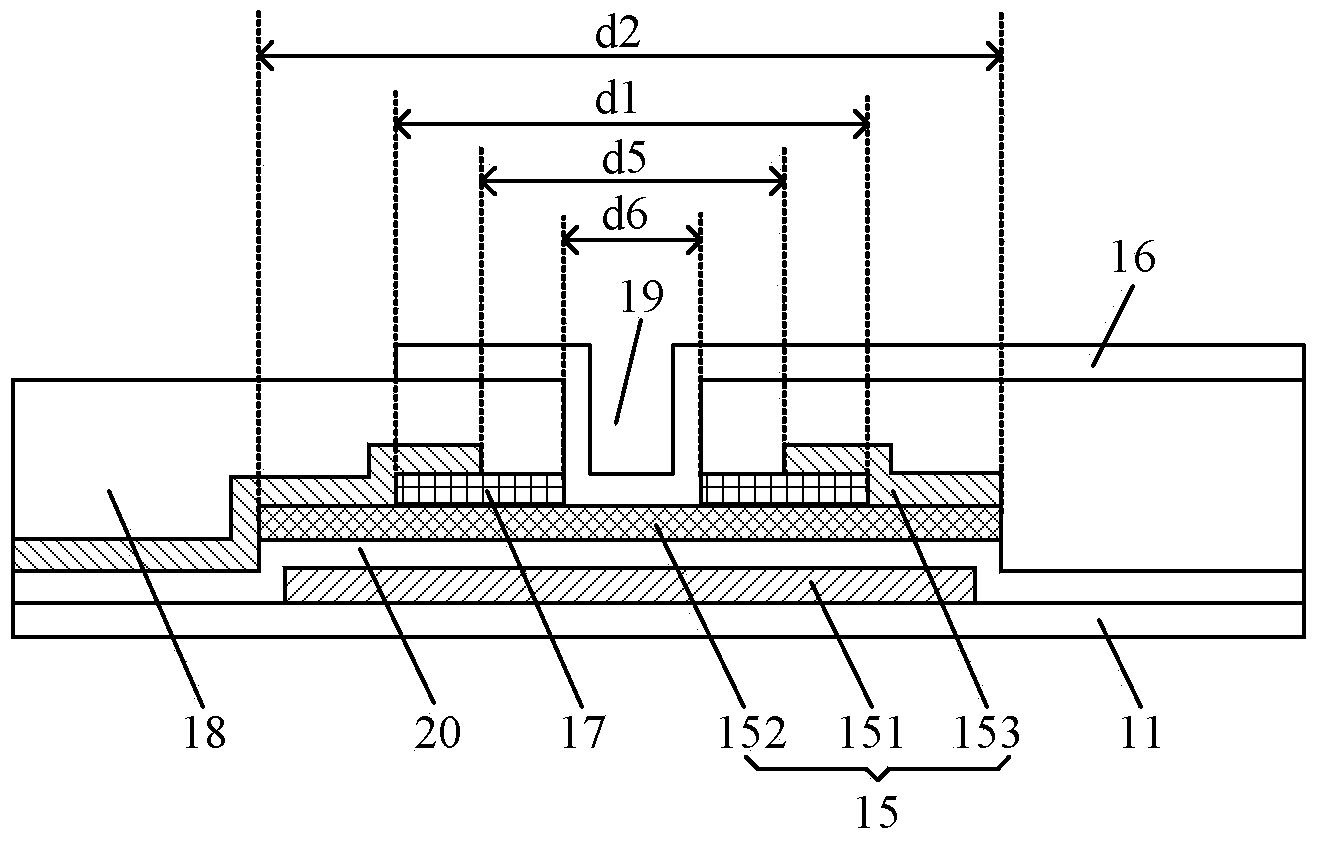

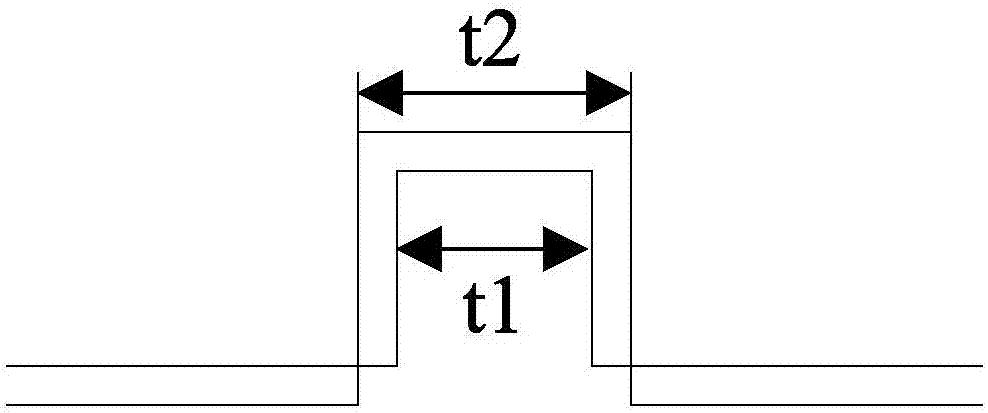

Pixel structure and array substrate

ActiveCN107479289AIncrease charging currentImprove charging effectStatic indicating devicesNon-linear opticsCapacitanceCapacitor

The embodiment of the invention discloses a pixel structure and an array substrate. The pixel structure comprises a pixel unit, a data line and a first scanning line. The pixel unit comprises a thin film transistor TFT and a pixel electrode; the grid electrode of the TFT is electrically connected with the first scanning line; one end of the drain electrode and the source electrode of the TFT is electrically connected with the data line, and the other end of the drain electrode and the source electrode of the TFT is electrically connected with the pixel electrode; a liquid crystal capacitor is formed between the pixel electrode and a common electrode; a storage capacitor is formed between the pixel electrode and a second scanning line, and the second scanning line is the next scanning line of the first scanning line. After the TFT is started, the data line charges the pixel electrode; in the charging process, the driving voltage on the second scanning line is adjusted to second voltage from first voltage. According to the pixel structure and the array substrate, the charging performance can be improved, and the display effect can be improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Terminal charging method, device and terminal

ActiveCN105244936AImprove experienceIncrease charging rateBatteries circuit arrangementsSecondary cells charging/dischargingThermal energyCharge current

The invention discloses a terminal charging method, a device and a terminal. The method comprises steps: at a first moment during a terminal charging process, a first application currently operated by a backstage and first thermal energy data of the terminal are determined; at a second moment during the terminal charging process, a second application currently operated by the backstage and second thermal energy data of the terminal are determined, and a first time interval exists between the second moment and the first moment; when the first application and the second application are different, the difference value between the second thermal energy data and the first thermal energy data is determined; and when the difference value between the second thermal energy data and the first thermal energy data is larger than a first set threshold, charging current is adjusted. When the embodiment of the invention is applied, relatively-constant charging current can be provided for the terminal, temperature of the terminal can be ensured not to rise too quickly, the charging speed during the process of using the terminal while charging is improved, and user experience is enhanced.

Owner:XIAOMI INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com