Processing for manufacturing metallized polypropylene film capacitor

A polypropylene film and manufacturing process technology, applied in film/thick film capacitors, laminated capacitors, wire wound capacitors, etc., can solve the problems of low reliability of edge flashover, large capacitor volume, capacitor failure, etc., and achieve metal loss Small, improved charging current and withstand voltage, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

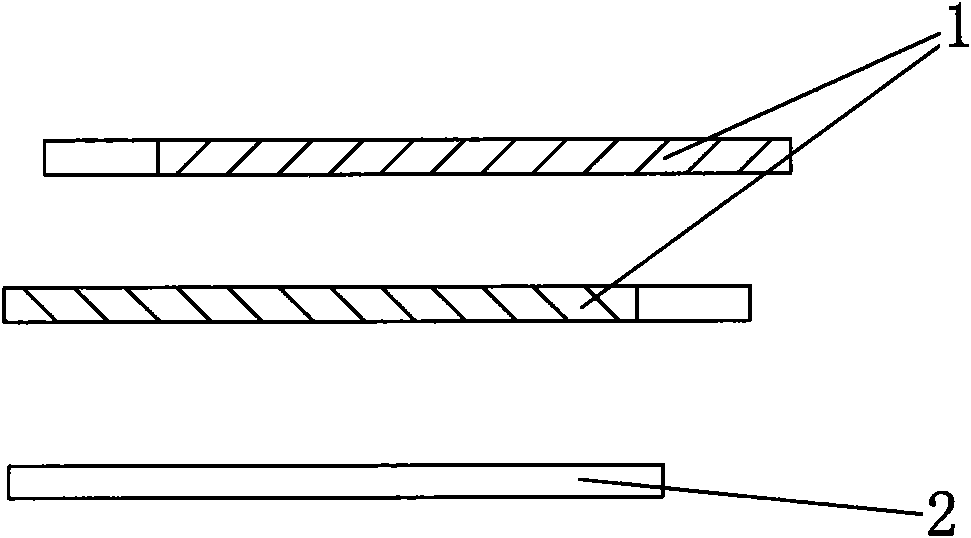

Image

Examples

Embodiment Construction

[0020] The specific process steps of the present invention are as follows: first cut the single-edge vapor-deposited polypropylene film and the polypropylene film into specified specifications, then stack them in layers, wind them into capacitor cores, and place the wound cores in a hot On the flat plate of the molding machine, cover a layer of epoxy cloth for shaping, and wrap a layer of adhesive tape on the surface of the core that has been stabilized by hot pressing. 1mm for the next process. Place the wrapped core and any end exposed on the end face on the turntable of the gold spraying machine. After adjustment, carry out gold spraying treatment. As long as the edge of the end mask is not burned, use dust removal equipment to suck away the floating dust metal particles, and put the metal connection point line on the surface of the core after spraying gold into the fixture of the capacitor energizing machine and connect it to 1-2A, 50V DC , and then use twice the rated vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com