Insulated gate bipolar transistor (IGBT) driving push-pull circuit

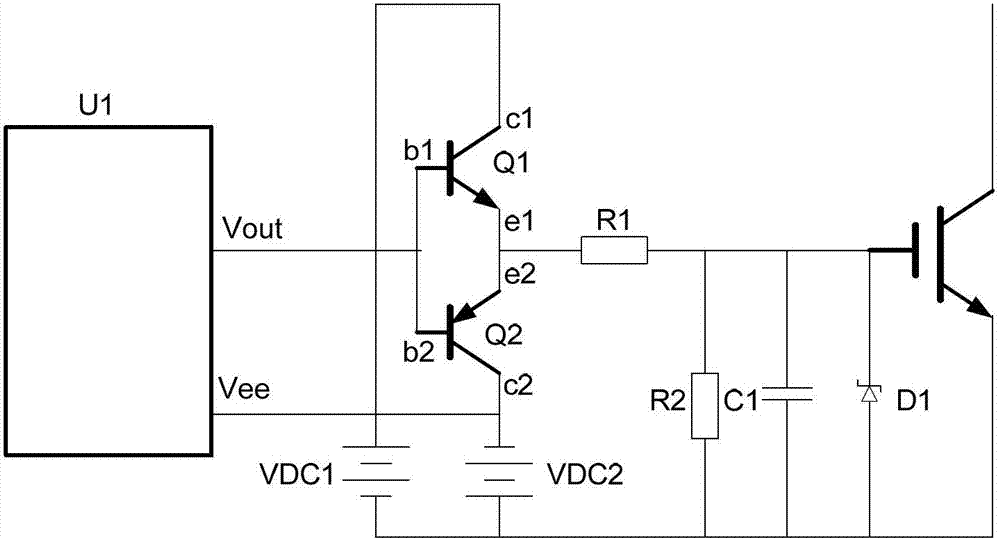

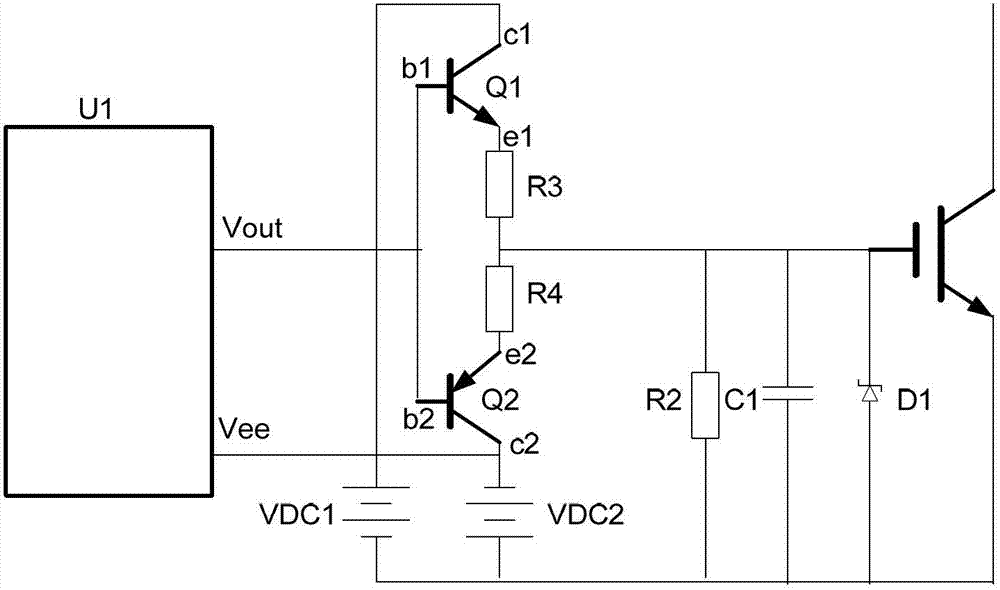

A push-pull circuit and resistor technology, applied in electrical components, electronic switches, pulse technology, etc., can solve the problems of large loss of NPN transistors and PNP transistors, small charge and discharge current peaks, etc., to improve the turn-on and turn-off speed, reduce Loss, the effect of increasing the charge current and discharge current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

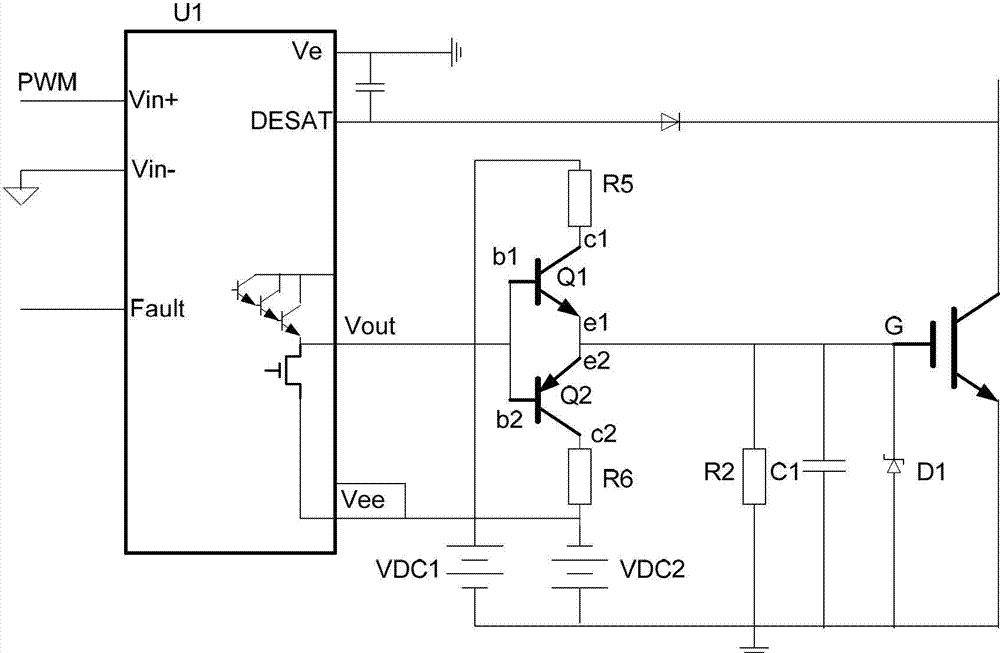

[0014] The IGBT driving push-pull circuit of the present invention is as image 3 As shown, the push-pull circuit mainly includes NPN transistor Q1, PNP transistor Q2, charging resistor R5 and discharging resistor R6. One end of the charging resistor R5 is connected to the positive pole of the input power supply VDC1, and the other end of the charging resistor R5 is connected to the collector c1 of the NPN transistor Q1; the emitter e1 of the NPN transistor and the emitter e2 of the PNP transistor Q2 are connected to one point and connected to the IGBT The gate G is connected. The emitter c2 of the PNP transistor is connected to one end of the discharge resistor R6, and the other end of the discharge resistor is connected to the ground of the power supply VDC2.

[0015] In the present invention, the driving main chip U1 connecting the weak current control signal and the push-pull circuit can be HCPL-316J, ACPL-38JT, EXB841, HCPLJ312, etc., wherein the PWM output terminal Vout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com